Permanent-magnet rotor deflection-type three-degree-of-freedom motion motor

A permanent magnet rotor, degree of freedom technology, applied in electrical components, holding devices with magnetic attraction or thrust, etc., can solve the problems of large wear and poor torque output capability of three-degree-of-freedom motion motors, and improve dynamic response and performance. Positioning accuracy, strong torque output capability, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

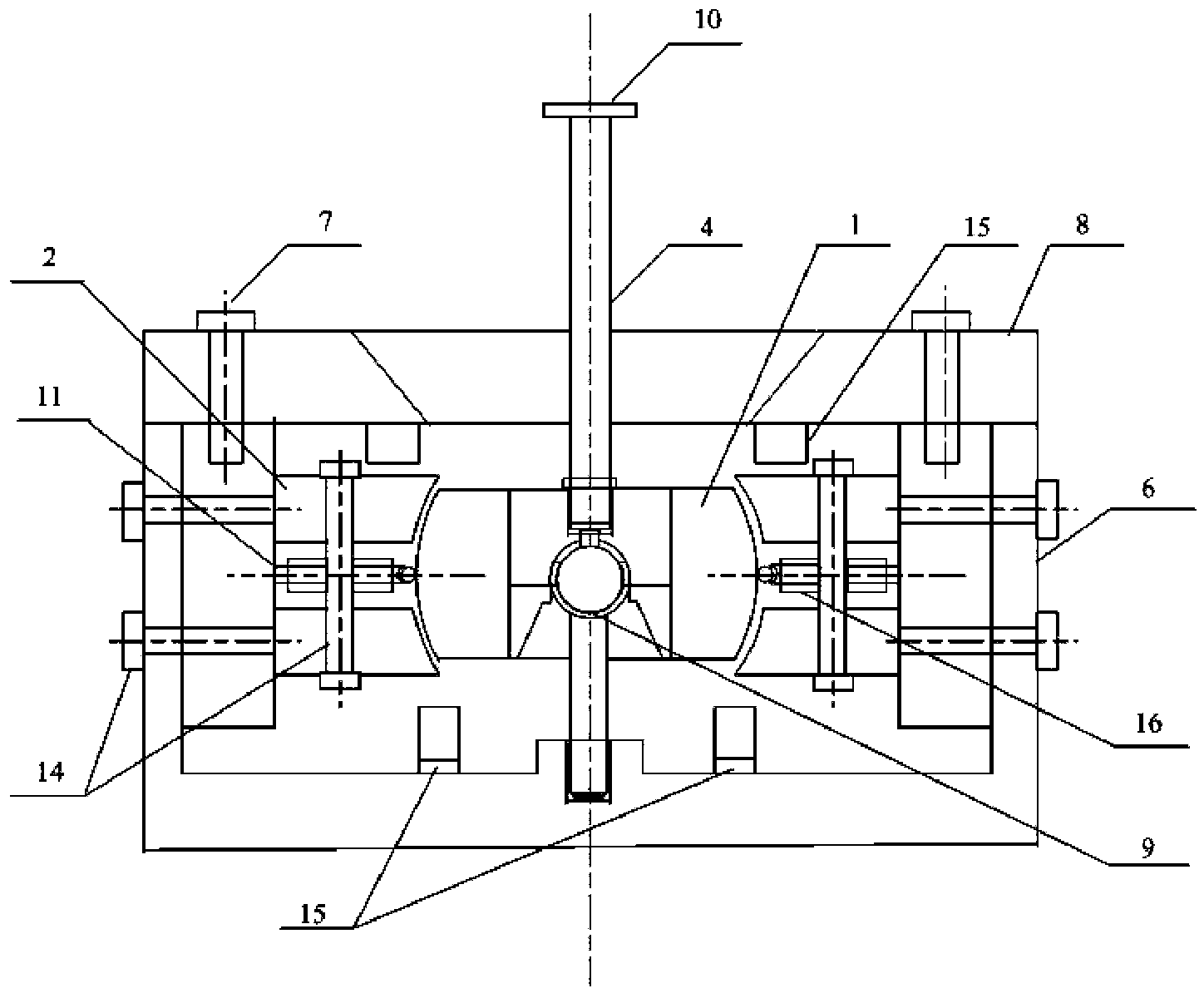

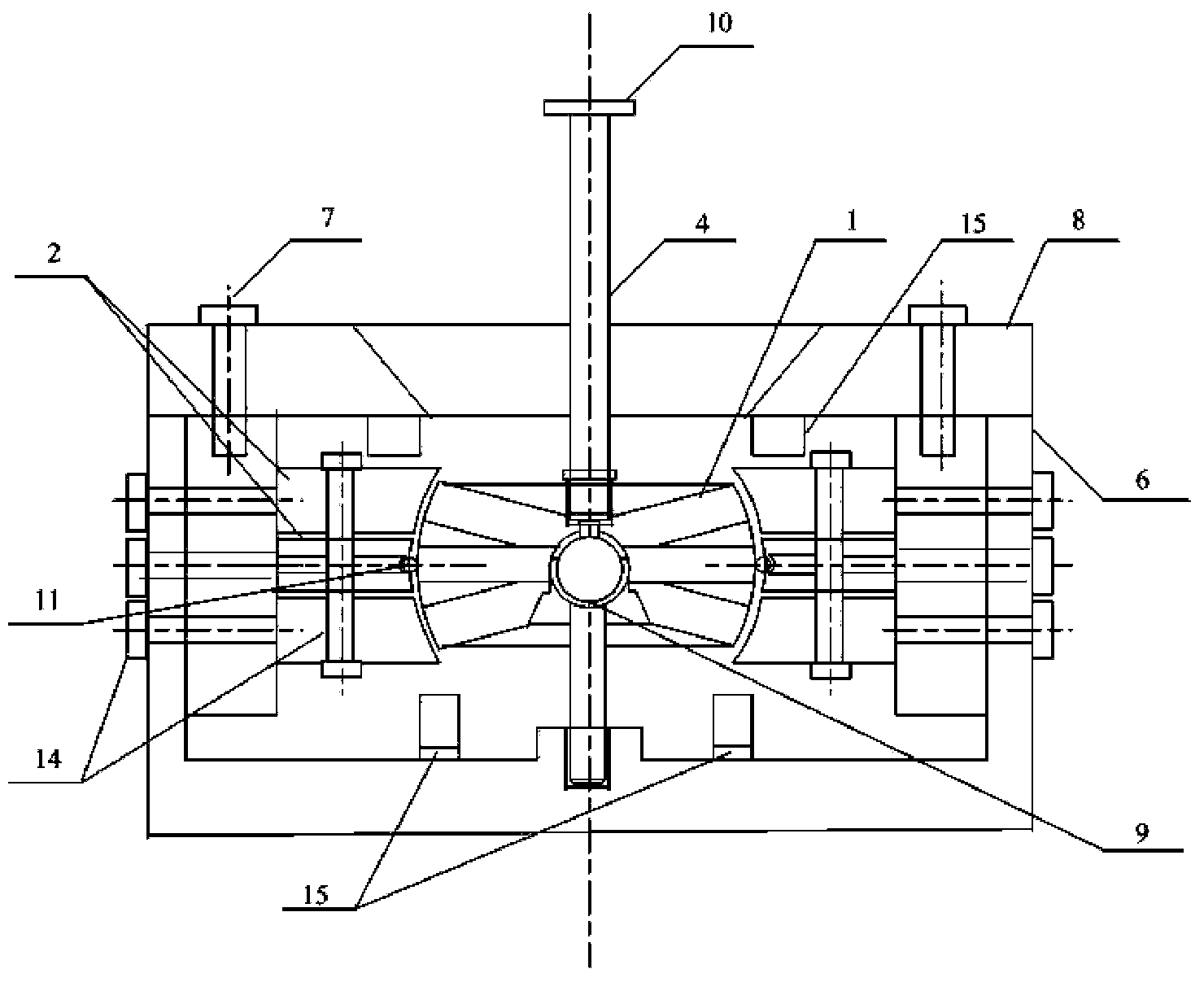

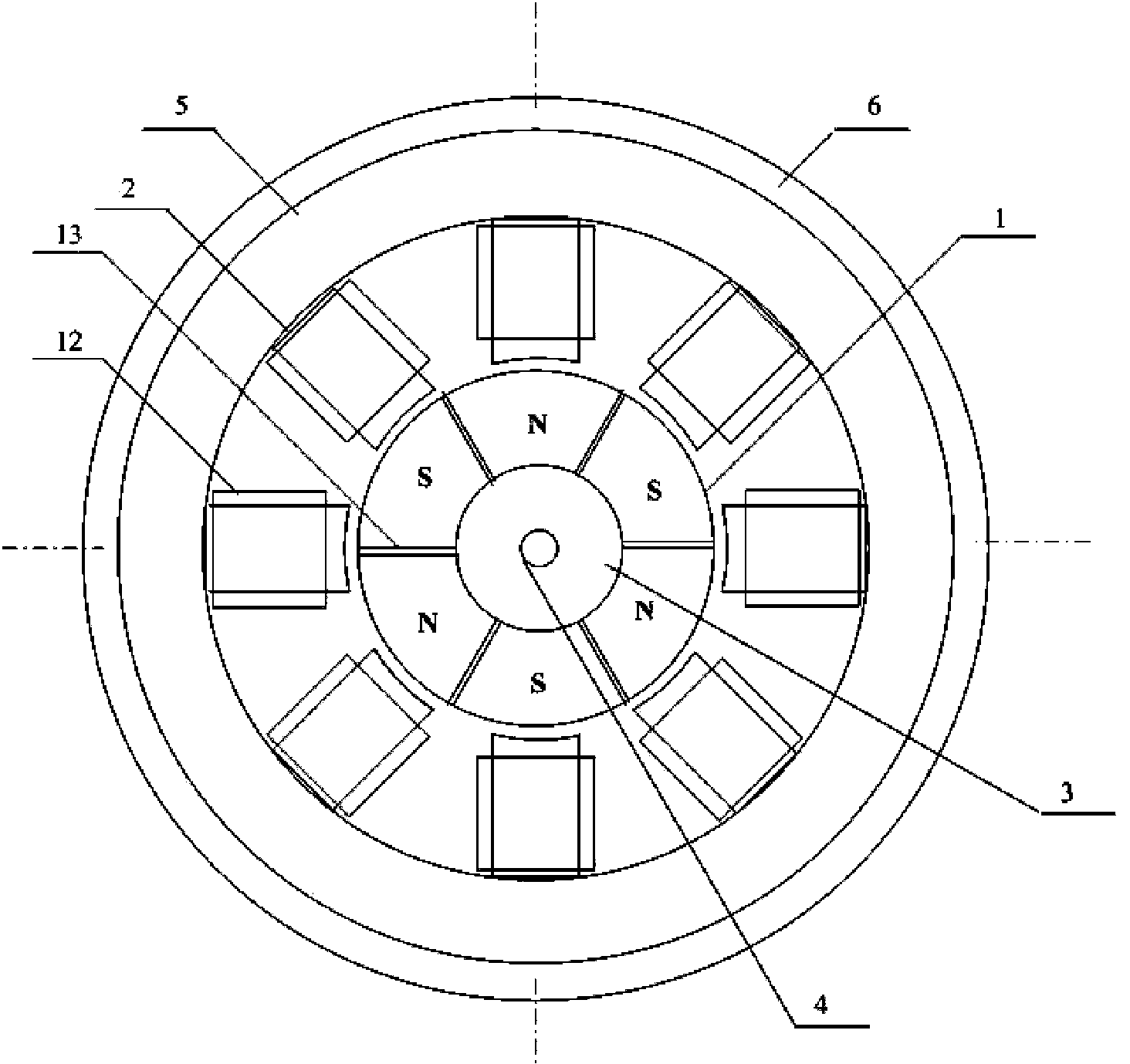

[0039] see figure 1 , 2 , 3 and 4, the drum-shaped and butterfly-shaped rotors are composed of magnetic poles 1 made of permanent magnetic materials and magnetic spacers 13 between the magnetic poles. The motor body has stators, coils and rotors. The base and stator shell 6 are fixed as one. The shell The end cover 8 is in the shape of a trumpet with an opening on the side of the output shaft, and fixing screw holes are distributed on the inner surface of the casing to fix the stator core 2, the bearing 9 and the magnetic sensor group 15 respectively.

[0040] On the rotor, permanent magnet slots are distributed according to the principle of equal division. The permanent magnets arranged radially along the output shaft in the adjacent permanent magnet slots are distributed alternately with N poles and S poles. The drum-shaped rotor has a single-layer structure, and the butterfly rotor The cross structure constitutes a three-layer structure; the bottom adjustable screw ball be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com