Step-down type conversion circuit

一种变换电路、电阻的技术,应用在电气元件、直流功率输入变换为直流功率输出、调节电变量等方向,能够解决操作不便、浪费人力和时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

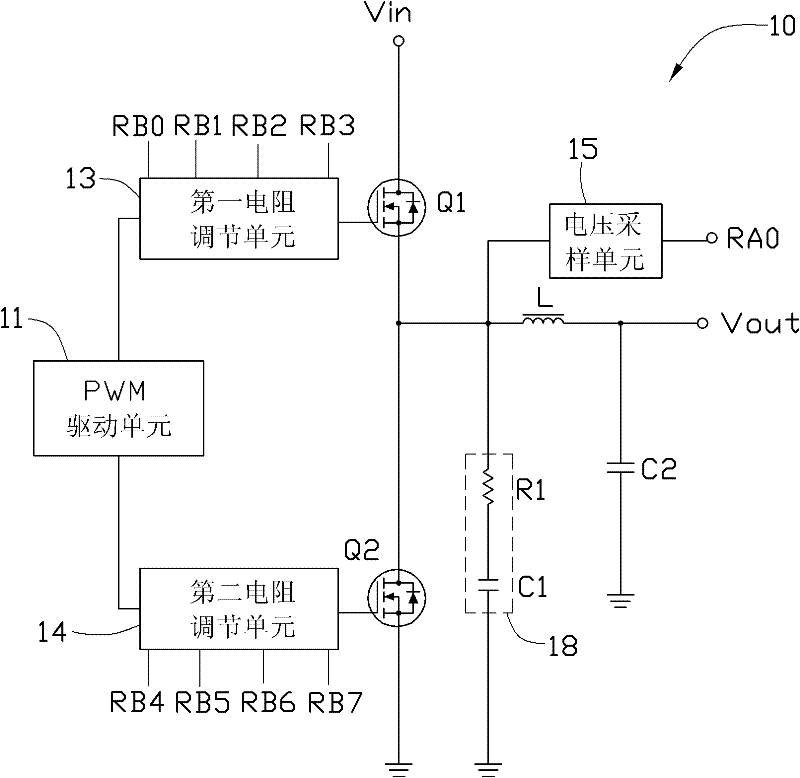

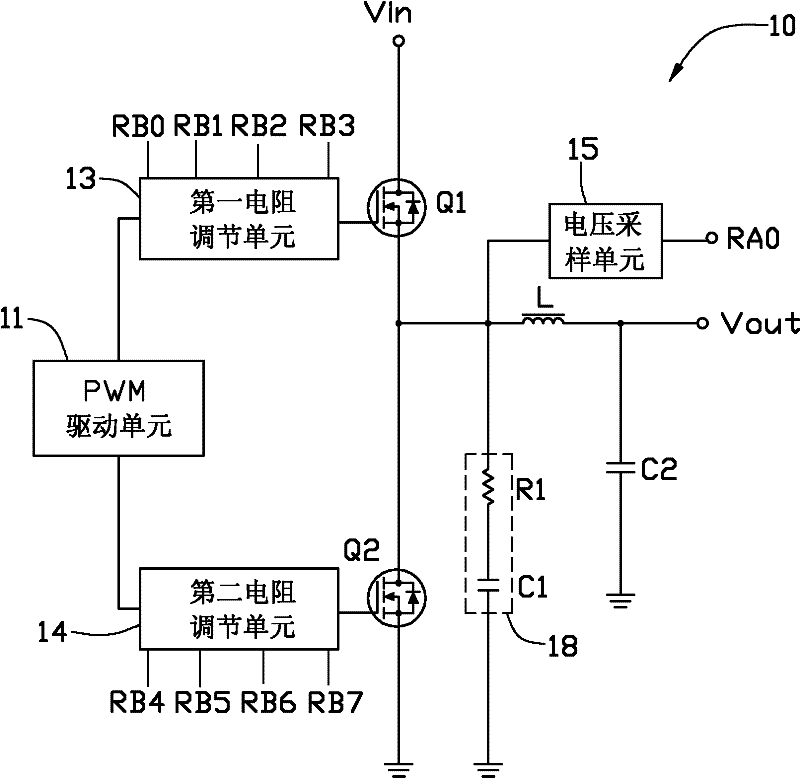

[0039] Please refer to figure 1 and figure 2 A preferred embodiment of the present invention provides a step-down conversion circuit 10, including a voltage input terminal Vin, a PWM (pulse width modulation, pulse width modulation) drive unit 11, a first field effect transistor Q1, a second field effect transistor Q2, a voltage The sampling unit 15 , the control unit 12 , the first resistance adjustment unit 13 , the second resistance adjustment unit 14 , the switch unit 16 , the display unit 17 and the voltage output terminal Vout.

[0040] The voltage input terminal Vin is connected to the drain of the first field effect transistor Q1 to input the external power into the step-down conversion circuit 10 . The source of the first FET Q1 is connected to the drain of the second FET Q2. The drain of the second field effect transistor Q2 is grounded through the inductor L and the second capacitor C2 connected in series. The voltage output terminal Vout is connected between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com