Curved-surface pyramidal micro-lens array and rear projection screen with the lens array

A micro-lens array, pyramid-shaped technology, applied in the directions of lenses, optics, instruments, etc., to achieve the effect of improving contrast, large field of view, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

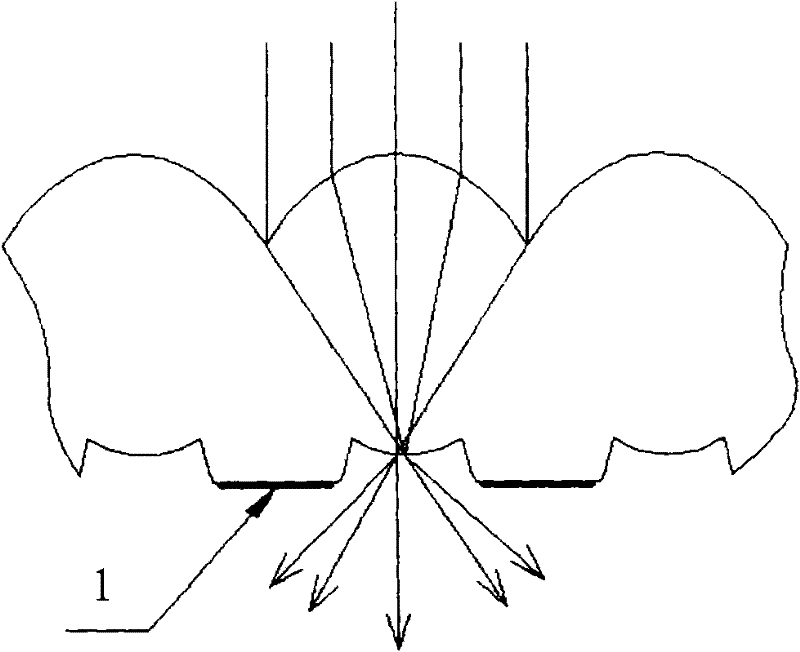

[0026] like Figure 4 , Figure 5 As shown, the curved pyramid microlens array 6 of the present invention is composed of a plurality of curved pyramid microlens units 7 having the same structure as an array structure with the same number of rows and columns, and each curved pyramid microlens unit 7 is tapered as a whole , all have a bottom surface, a top surface and four sides connecting the bottom surface and the top surface; the bottom surface of the curved pyramid microlens unit 7 is a square, the top surface is a spherical surface, and the side surfaces are arc surfaces with a certain curvature. The divergence of the outgoing light through the curved pyramid-shaped microlens unit 7 is related to the curved pyramid-shaped side angle (i.e. the angle between two opposite sides) α, the radius of curvature R2 of the side surface and the radius of curvature R1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com