Air conditioner

A technology for air conditioners and external air temperature, applied to refrigerators, compressors, mechanical equipment, etc., can solve the problems of large-scale outdoor units and complex control, and achieve the effect of suppressing sharp rise and stabilizing room temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

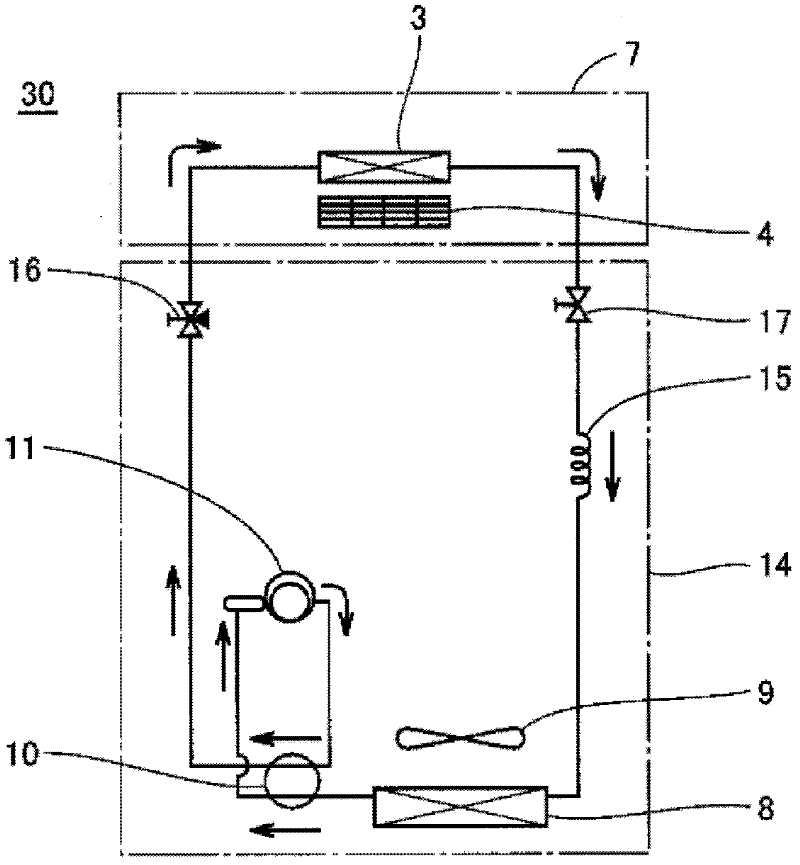

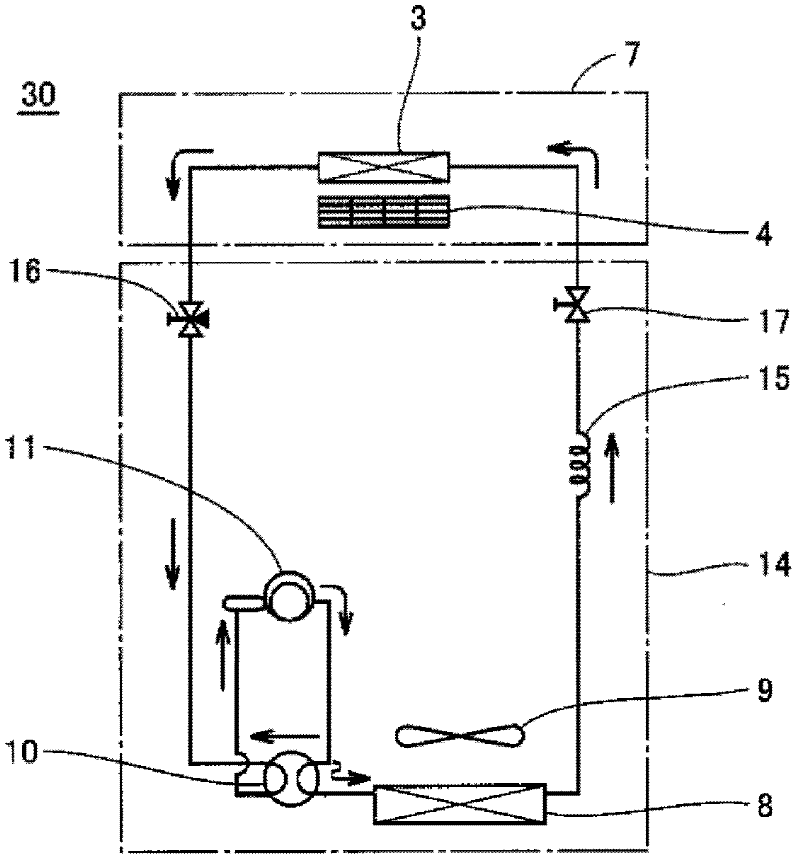

[0051] figure 1 It is a refrigerant|coolant circuit diagram which shows the structure of the air conditioner 30 which concerns on Embodiment 1 of this invention. figure 1 Indicates the flow of refrigerant during heating operation.

[0052] figure 1The air conditioner 30 is a separate device including the indoor unit 7 and the outdoor unit 14 . The indoor unit 7 includes an indoor heat exchanger 3 and an indoor fan 4 . The outdoor unit 14 includes: an outdoor heat exchanger 8 , an outdoor fan 9 , a four-way valve 10 , a compressor 11 , a capillary tube 15 as an expansion mechanism, a three-way valve 16 and a two-way valve 17 . As an expansion mechanism, an expansion valve can also be used instead of the capillary 15 .

[0053] The indoor fan 4 supplies indoor air to the indoor heat exchanger 3 . In the indoor heat exchanger 3, the indoor air supplied by the indoor fan 4 exchanges heat with the refrigerant. The outdoor fan 9 supplies outdoor air to the outdoor heat exchang...

Embodiment approach 2

[0094] In Embodiment 1, in Figure 8 In steps S8 and S12, when the temperature Thex1 of the outdoor heat exchanger 8 is equal to or higher than the defrosting end reference temperature (10° C.) (the first defrosting end condition), the defrosting operation is ended. However, when the outside air temperature is -20° C. or lower, the temperature of the outdoor heat exchanger 8 hardly rises even if the defrosting operation is performed. Therefore, if the defrosting operation is continued until the frost on the outdoor heat exchanger 8 is completely removed, the room temperature becomes too low.

[0095] Therefore, in the second embodiment, the defrosting operation is also terminated when the defrosting operation time exceeds the upper limit (the longest defrosting time) (the second defrosting end condition). The longest defrosting time is set at about 15 minutes. In addition, since the indoor fan 4 stops during the defrosting operation, the temperature sensor 1 cannot accuratel...

Embodiment approach 3

[0107] Since the higher the rotation speed of the outdoor fan 9, the more heat is used as sensible heat, so the outdoor heat exchanger 8 is less likely to be frosted. However, since the outdoor fan 9 is installed outdoors, it becomes a noise source when the rotation speed is too high. Therefore, the outdoor fan 9 is normally operated at a rotation speed lower than the maximum rotation speed.

[0108] And when the outdoor heat exchanger 8 starts to frost, since the fins are covered by frost, even if the rotating speed of the outdoor fan 9 is increased, the noise will hardly increase. Therefore, in Embodiment 3, the control unit 32 detects a state in which the outdoor heat exchanger 8 is not fully frosted, that is, a state in which partial frosting starts. And, when the outdoor heat exchanger 8 starts to partially frost, the controller 32 increases the rotation speed of the outdoor fan 9 by about 100 to 200 rpm compared to the normal rotation speed. In this way, since the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com