Cleaning machine for bottles or similar containers

A container and cleaning technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of skewed containers, damaged containers, occlusions, etc., to achieve the best sliding performance, avoid damage, and improve processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

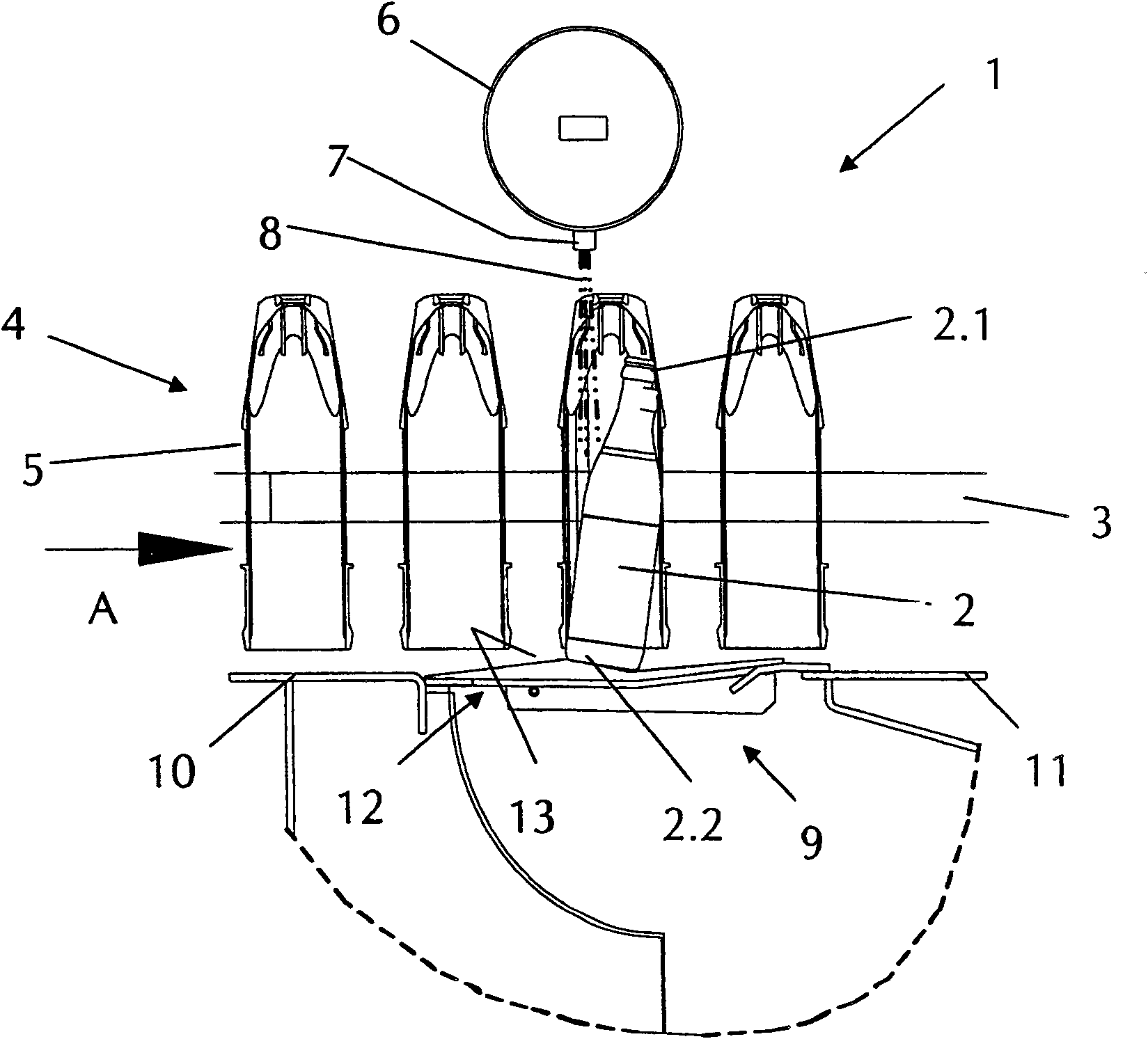

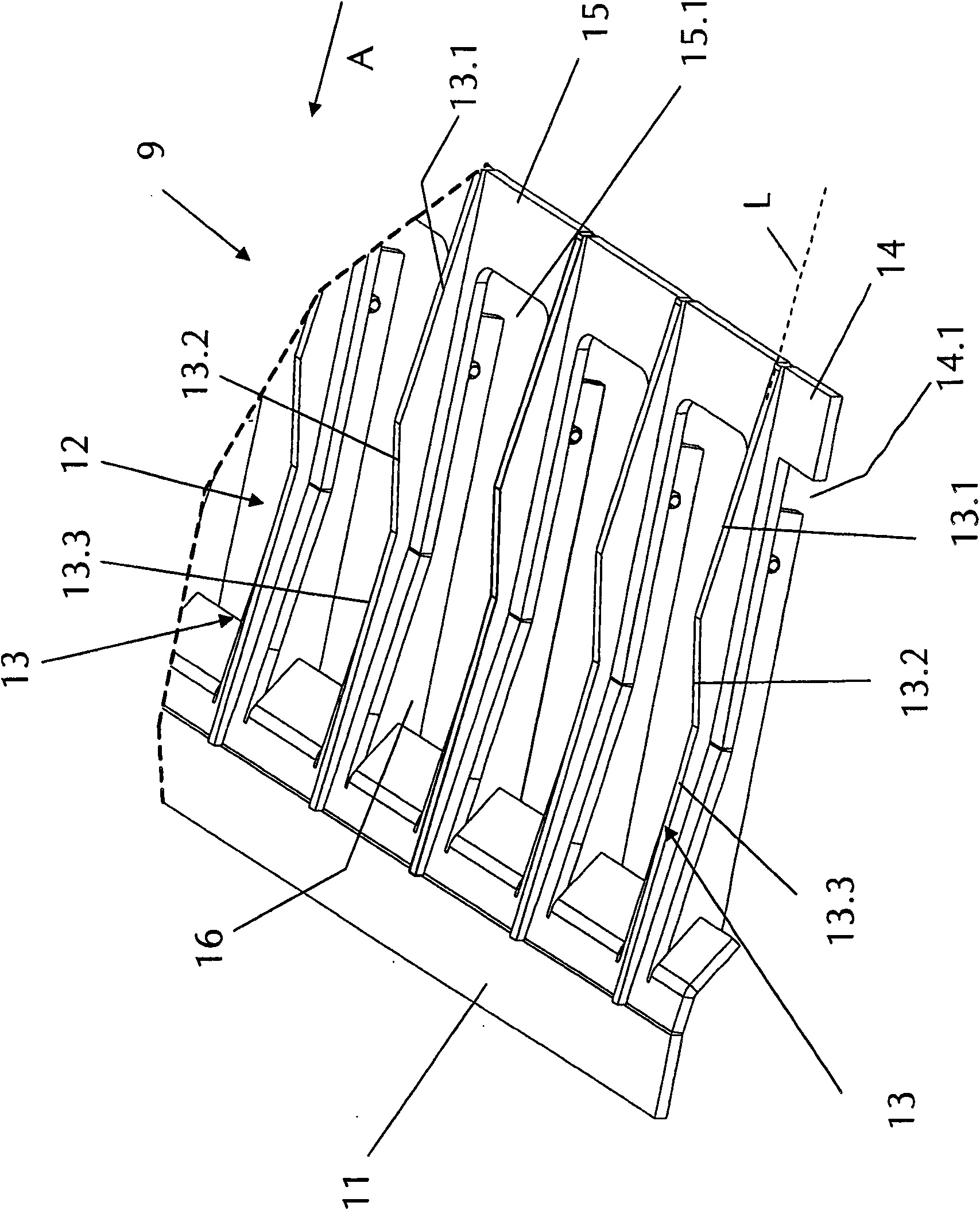

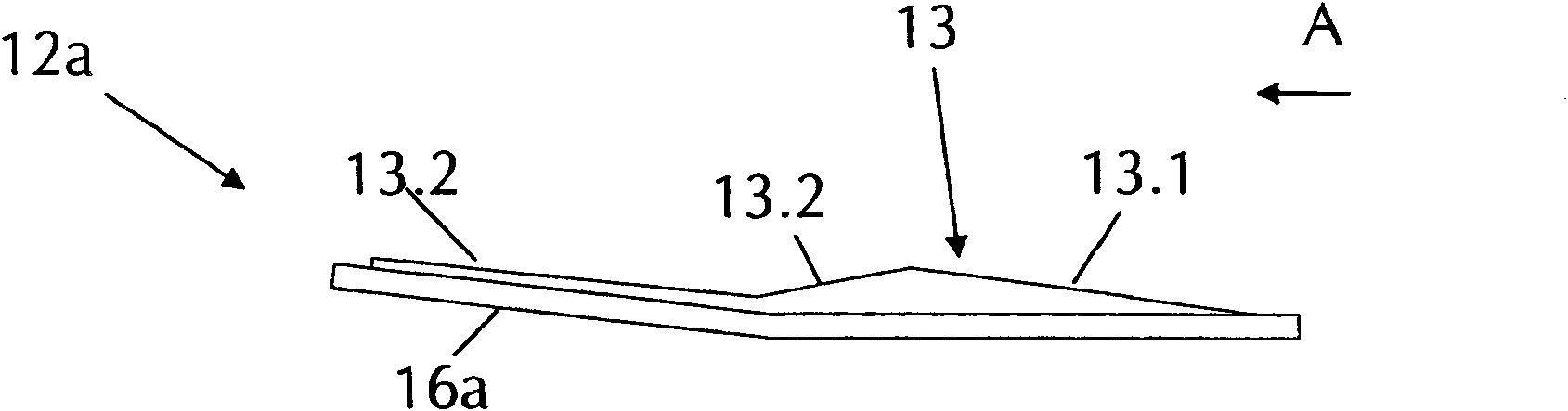

[0013] In the figures, reference numeral 1 designates a treatment area of a container or bottle cleaning machine, which is not otherwise shown and which comprises, in a manner known to a person skilled in the art, a conveying system which is driven in a continuous cycle, and the bottles 2 are moved by means of the conveying system between the bottle dispenser for the bottles to be cleaned and the bottle outlet for the cleaned bottles through a plurality of processing zones, including moving After treatment zone 1. In said treatment zone, spray washing of the bottles 2 takes place in particular on the outer or side surfaces of the bottles in order to remove any labels, label residues or other foreign matter.

[0014] In a manner also known to those skilled in the art, the conveyor system comprises a plurality of bottle cages 4 on a chain 3 driven in continuous circulation, each bottle cage having a plurality of bottle units 5, each for receiving A bottle 2 to be cleaned, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com