Printed circuit board

A technology of printed circuit boards and conductive paths, applied in printed circuits, printed circuit components, circuits, etc., can solve the problems of electrical connectors that cannot meet the requirements and the characteristic impedance becomes smaller, and achieve the effect of improving the characteristic impedance and reducing the capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

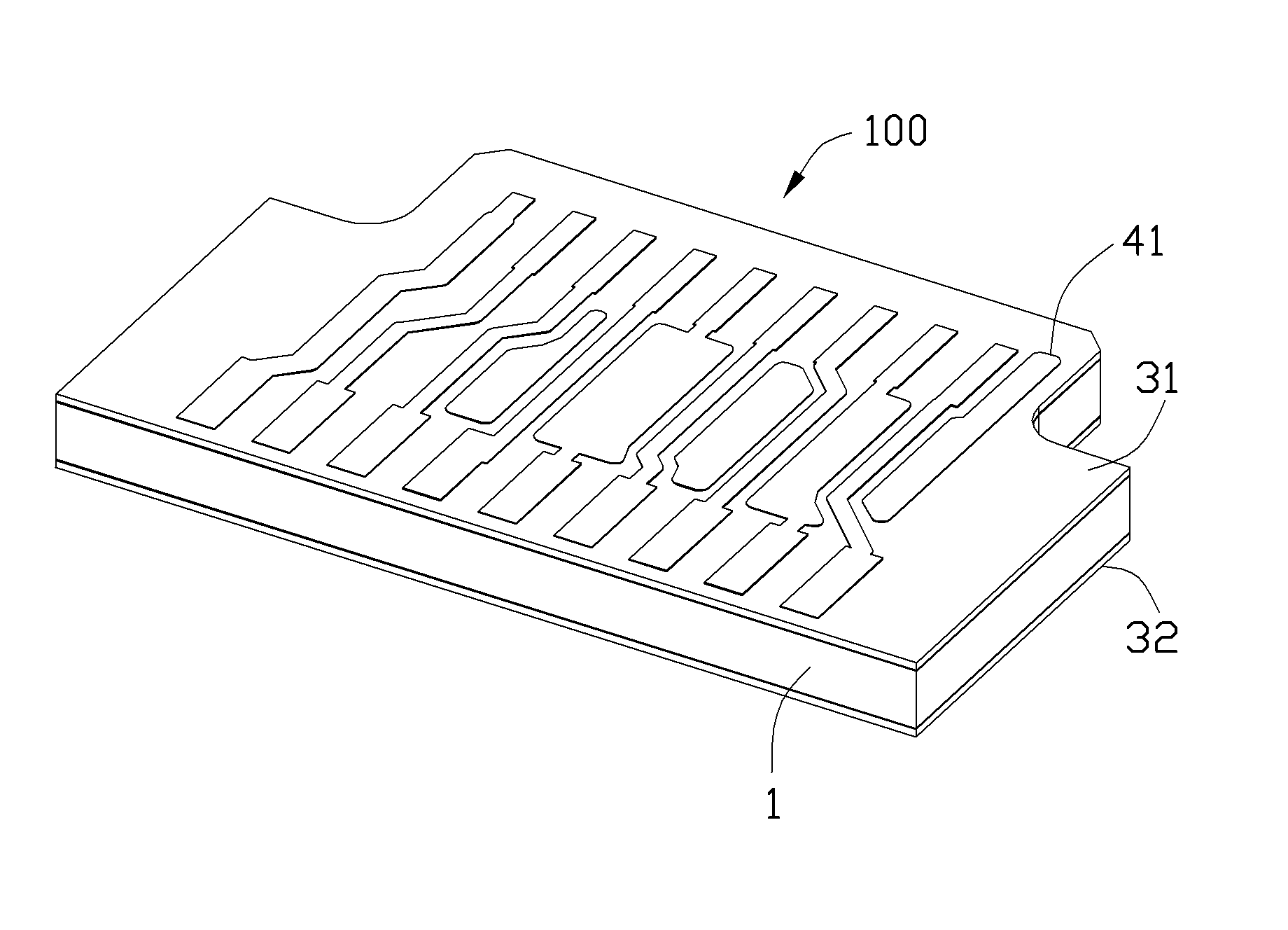

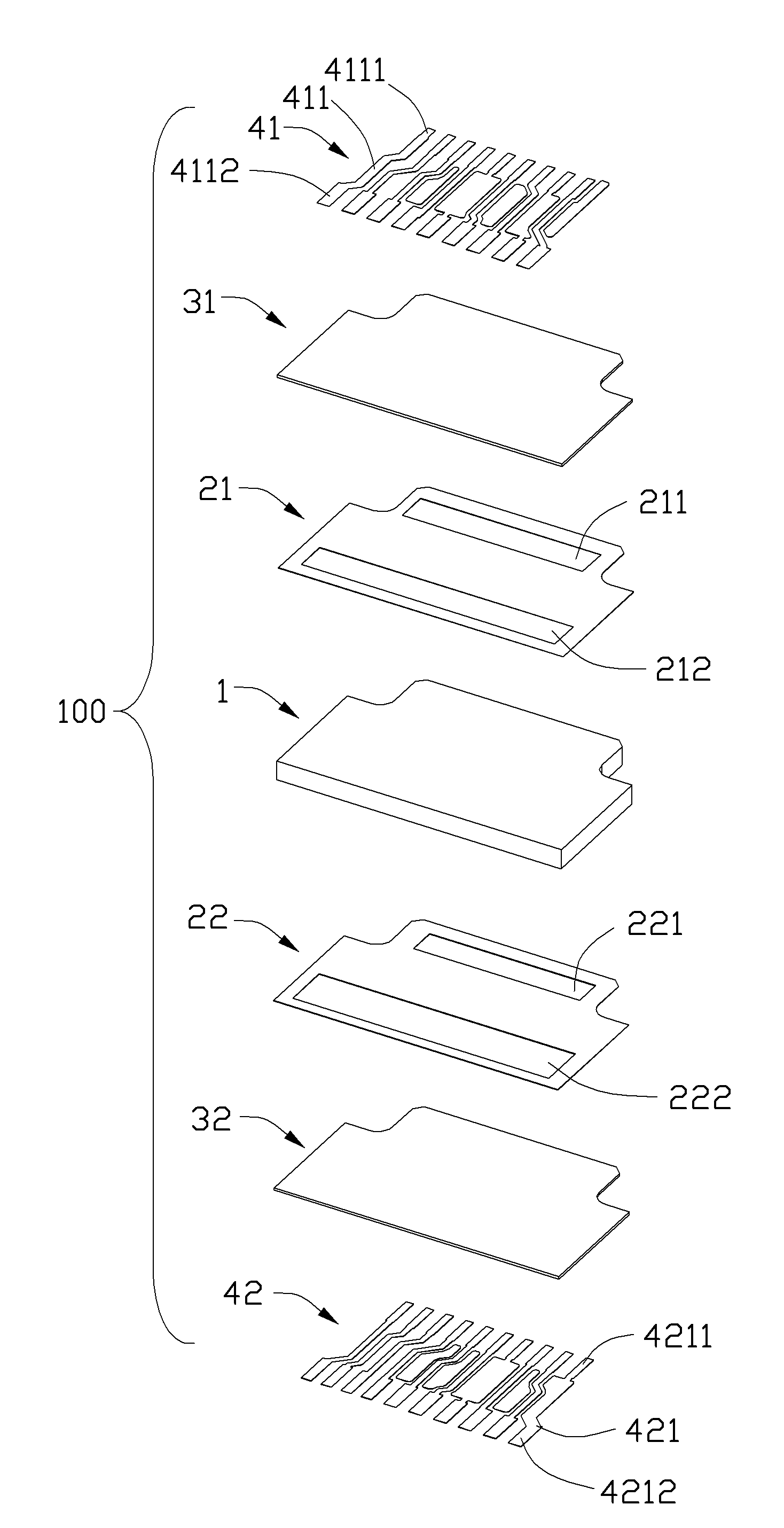

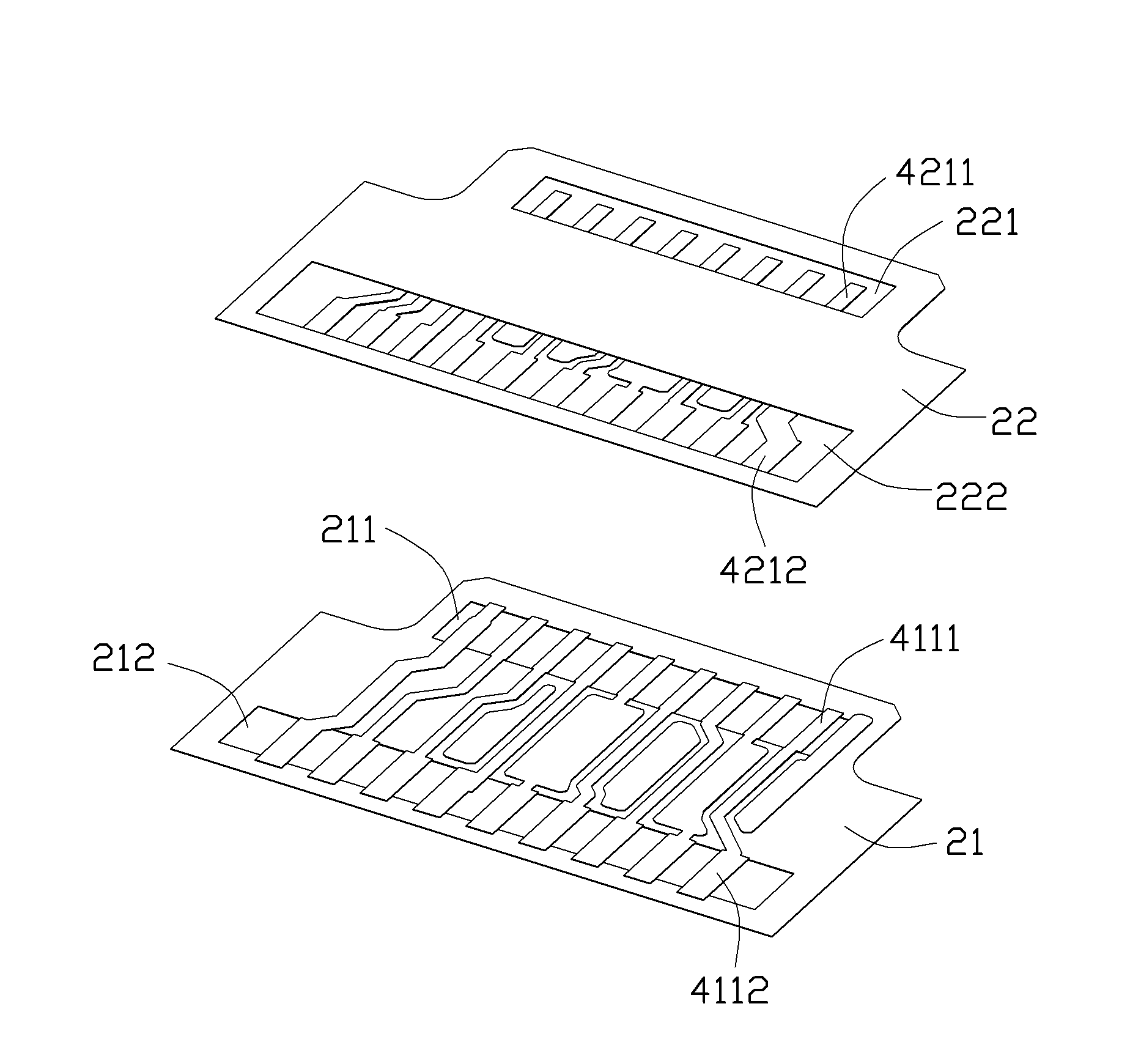

[0010] See Figure 1 to Figure 2 , The printed circuit board 100 of the present invention includes an insulating substrate 1, a first grounding layer 21, a second grounding layer 22, a first interlayer 31, a second interlayer 32, a first conductive path 41, and a second Conductive path 42. The printed circuit board 100 has a convex shape as a whole, but in other embodiments, it may also have other shapes.

[0011] The first ground layer 21 and the second ground layer 22 are printed by copper on the upper and lower surfaces of the insulating substrate 1, respectively. The first ground layer 21 is provided with a first through slot 211 at the front edge and a second through hole at the rear edge. The groove 212 and the second ground layer 22 are provided with a first through groove 221 at the front edge and a second through groove 222 at the rear edge. The first barrier layer 31 is located between the first ground layer 22 and the first conductive path 41, and the second barrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com