Dynamic characteristic model building method of chilling system, chilling system monitoring method and chilling method monitoring device

A technology of dynamic characteristics and model establishment, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inability to adjust and correct characteristic curves, maintenance, and inability to establish models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

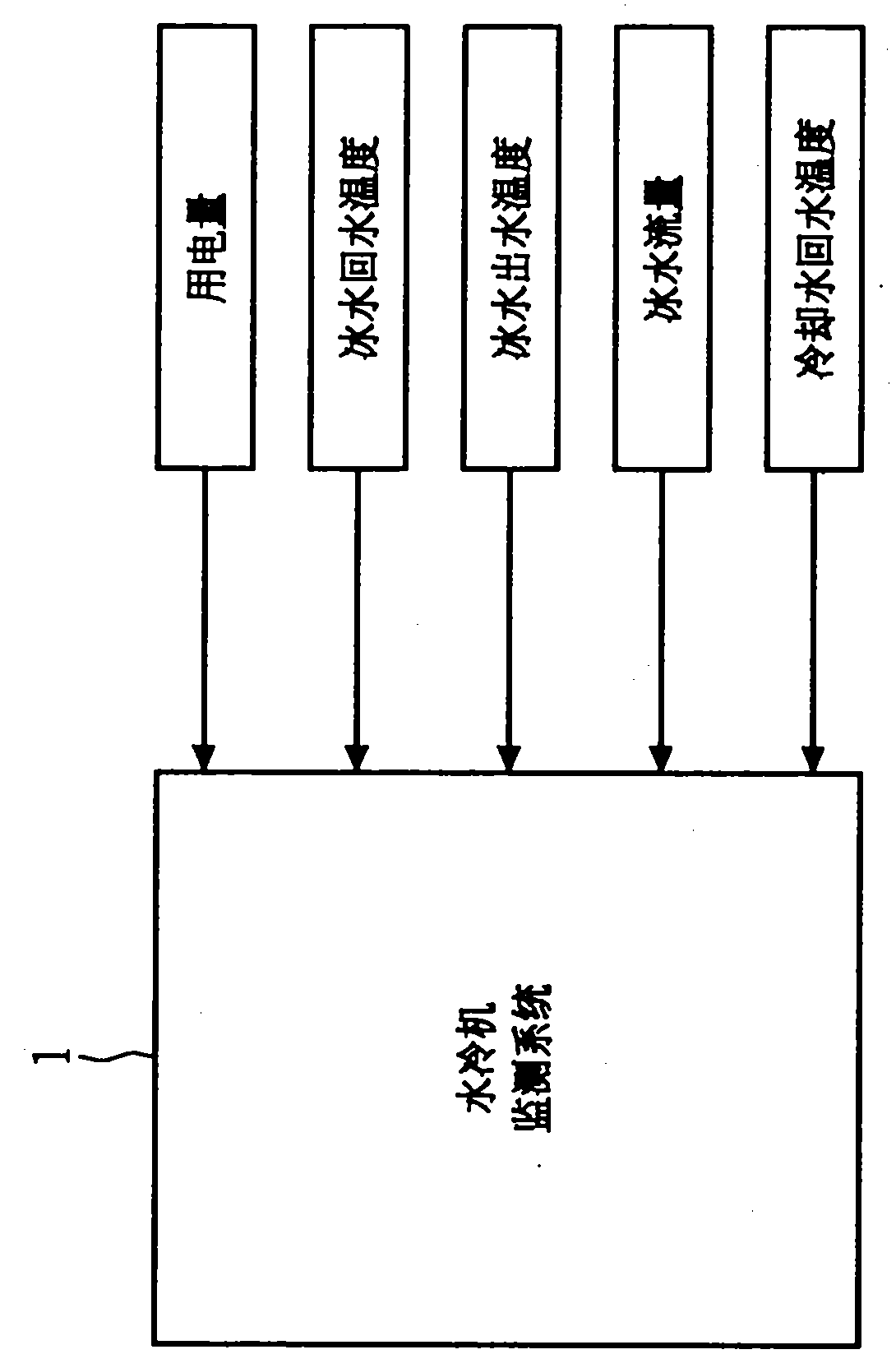

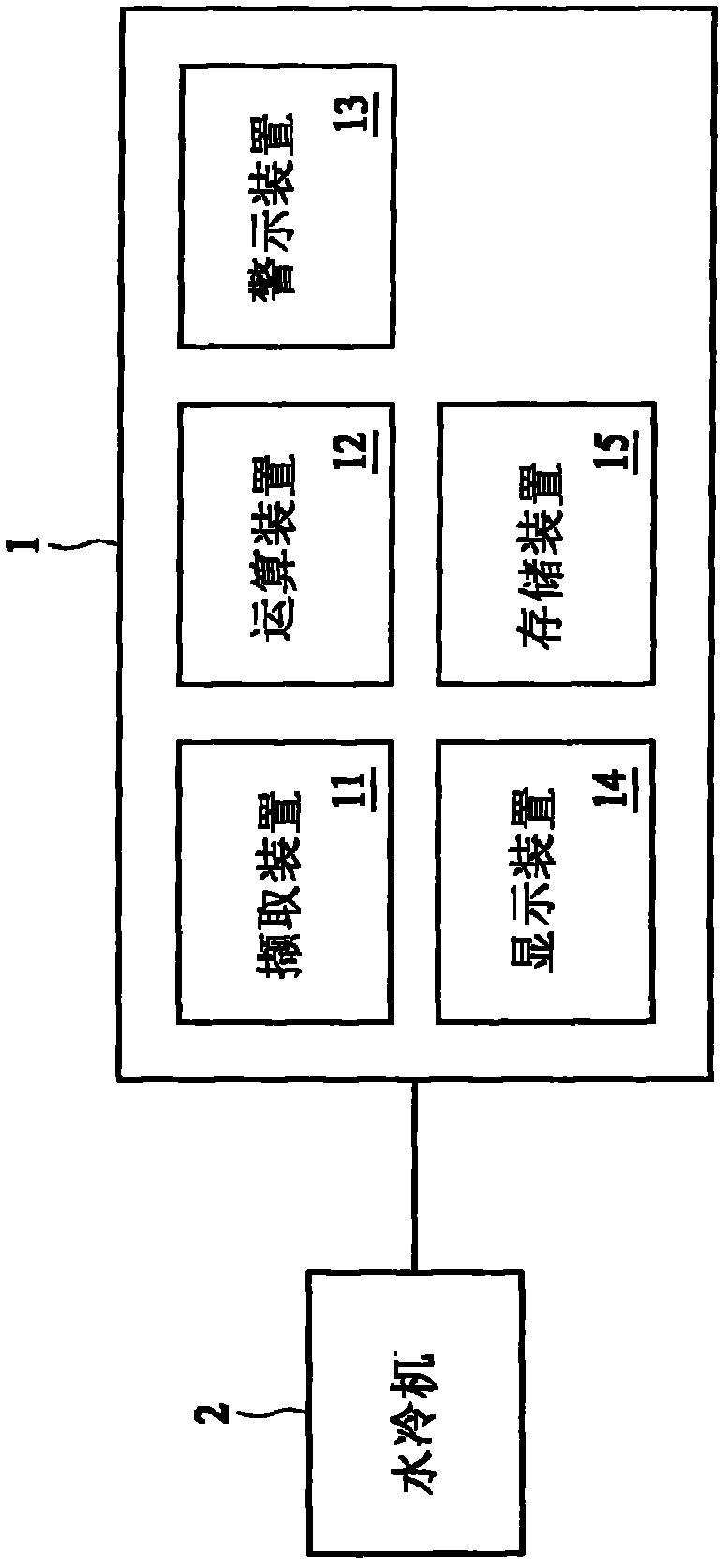

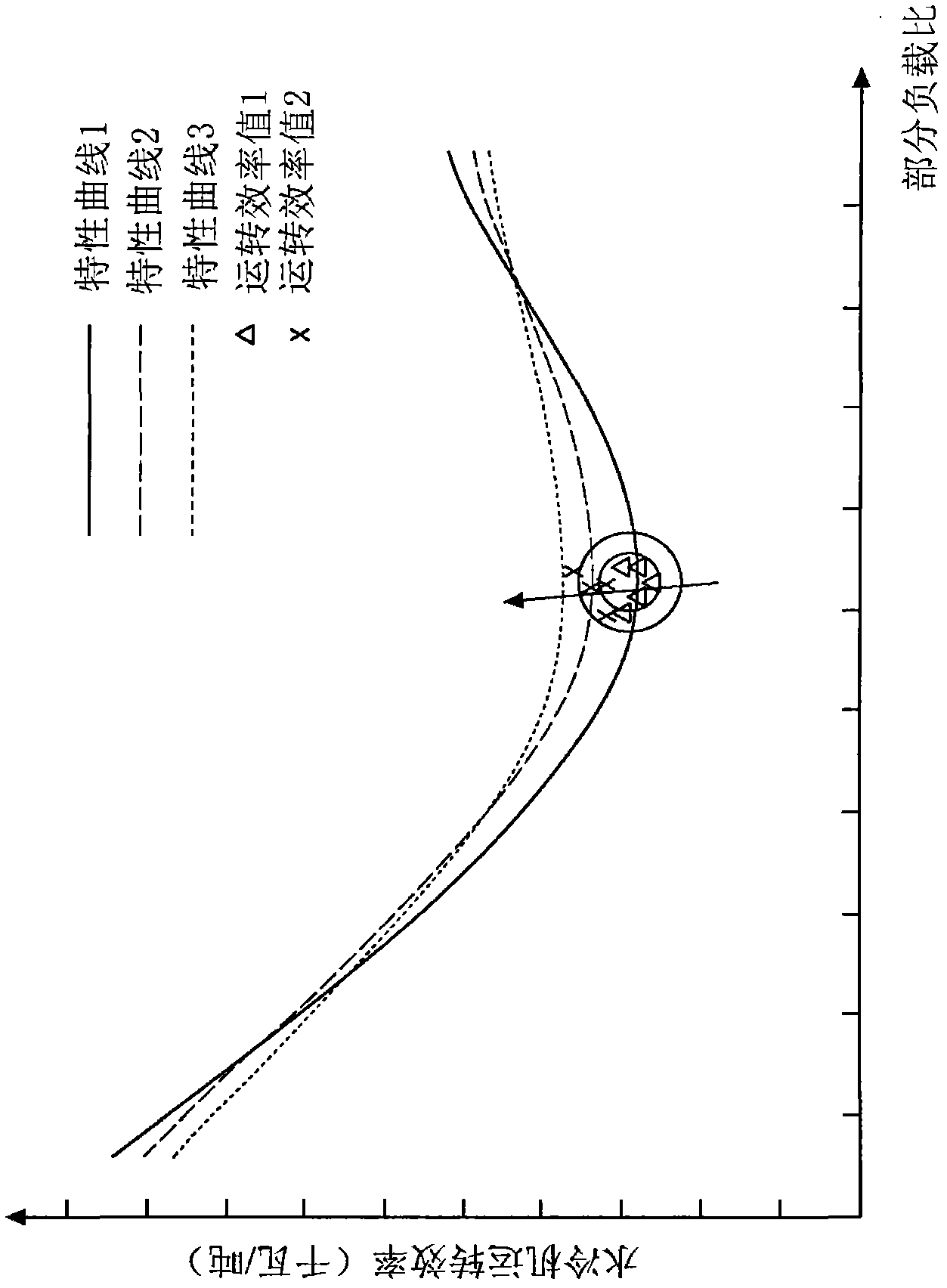

[0026] figure 1 A connection schematic diagram of the water chiller monitoring system 1 according to an embodiment of the present invention is shown. figure 2 A schematic diagram showing a water chiller monitoring system 1 according to an embodiment of the present invention. refer to figure 1 and figure 2 As shown, the water-cooler monitoring system 1 can be connected to the water-cooler or the factory management monitoring system (FMCS) 2, through the sensors on the water-cooler 2 or the factory database, the retrieval device 11 is used to obtain the relevant operation information of the water-cooler, the information includes There is the power consumption W of the water cooler 2, and the temperature T of the return water of the ice water chi , ice water outlet temperature T cho , Cooling water return temperature T cwi , and the ice water flow rate Q cho Wait for the operation information. Calculate the dynamic actual water-cooler operating efficiency (KPI) of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com