Method by catalyzing and hydrogenating animal and vegetable oil to produce high-quality diesel

A technology for catalytic hydrogenation of animal and vegetable fats and oils, which is applied in the fields of hydrogenation treatment process, preparation of liquid hydrocarbon mixture, petroleum industry, etc. It can solve the problems of raw material limitation, no freezing point of hydrogenation products, etc., and achieve the reduction of oxygen content, Strong resistance to water and the effect of extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

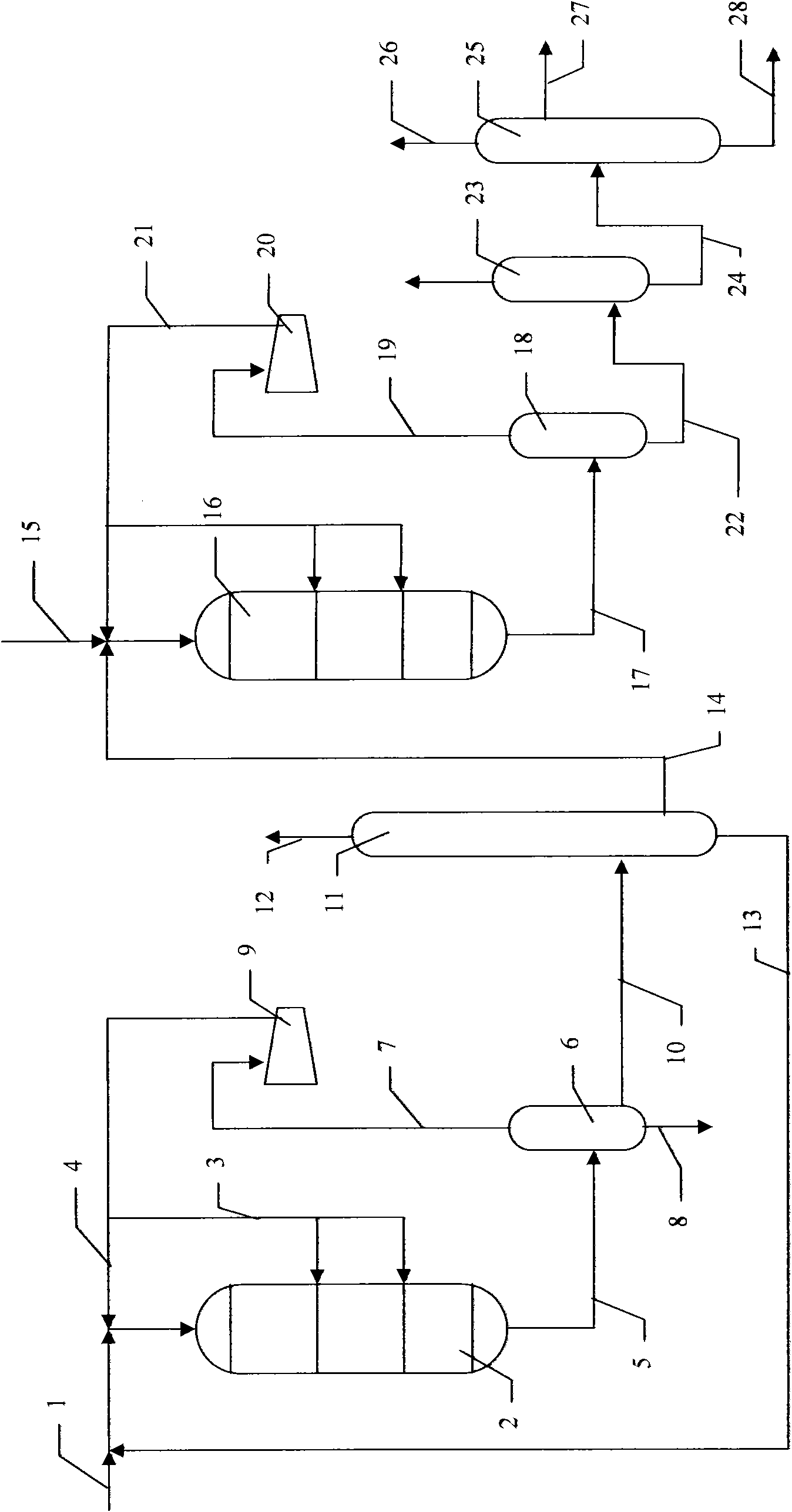

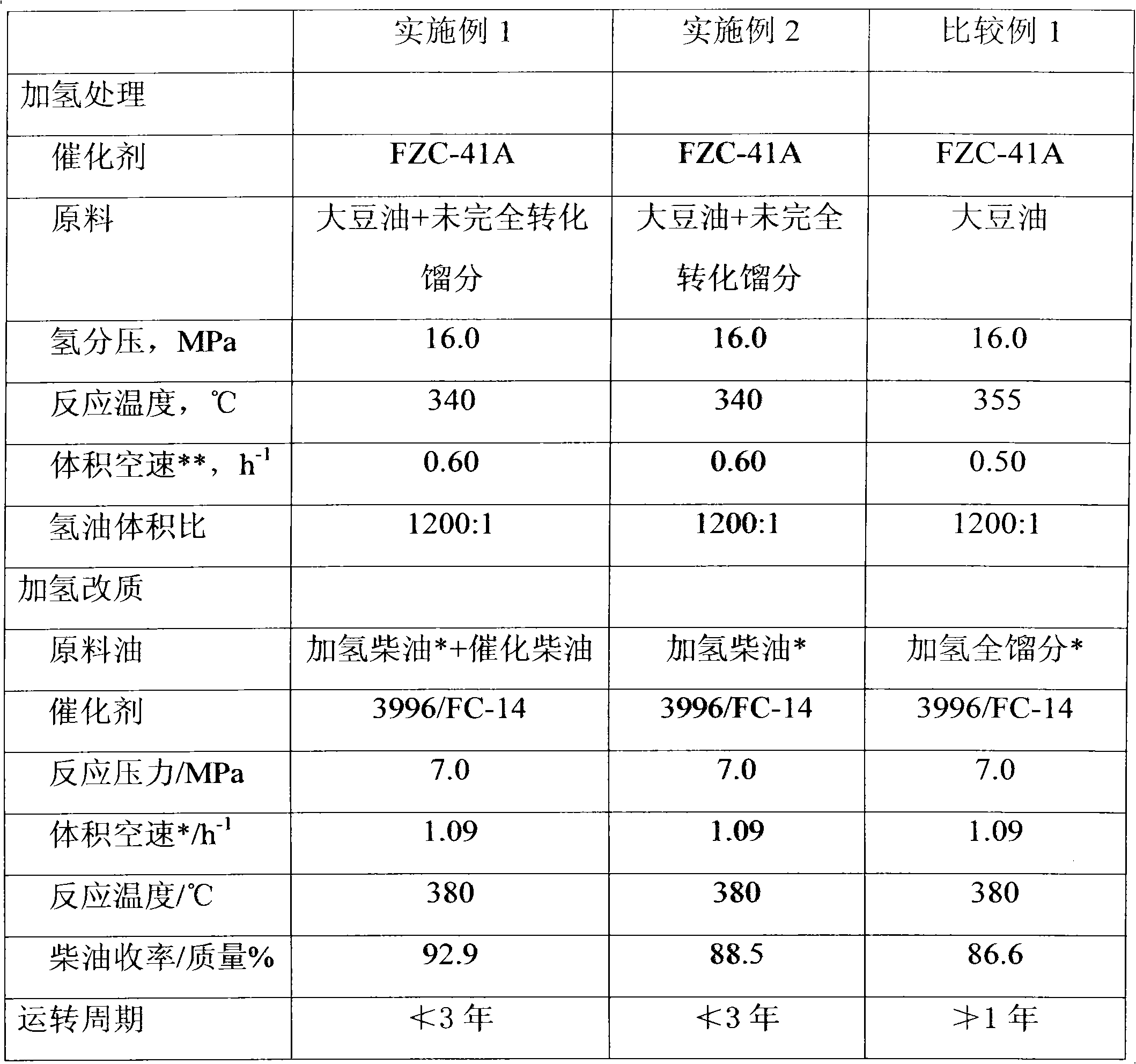

[0046] use figure 1 In the process flow shown, the raw material entering the hydro-upgrading unit includes not only the hydrotreated diesel fraction, but also the upgraded raw material outside the unit-catalytic cracking diesel.

[0047] The properties of the catalyst are listed in Table 1, wherein the hydrotreating catalyst FZC-41A is a supported oxidation state catalyst, which needs to be reduced with hydrogen before use to obtain a supported reduced metal catalyst, and the reduction of the catalyst is based on general knowledge in the field.

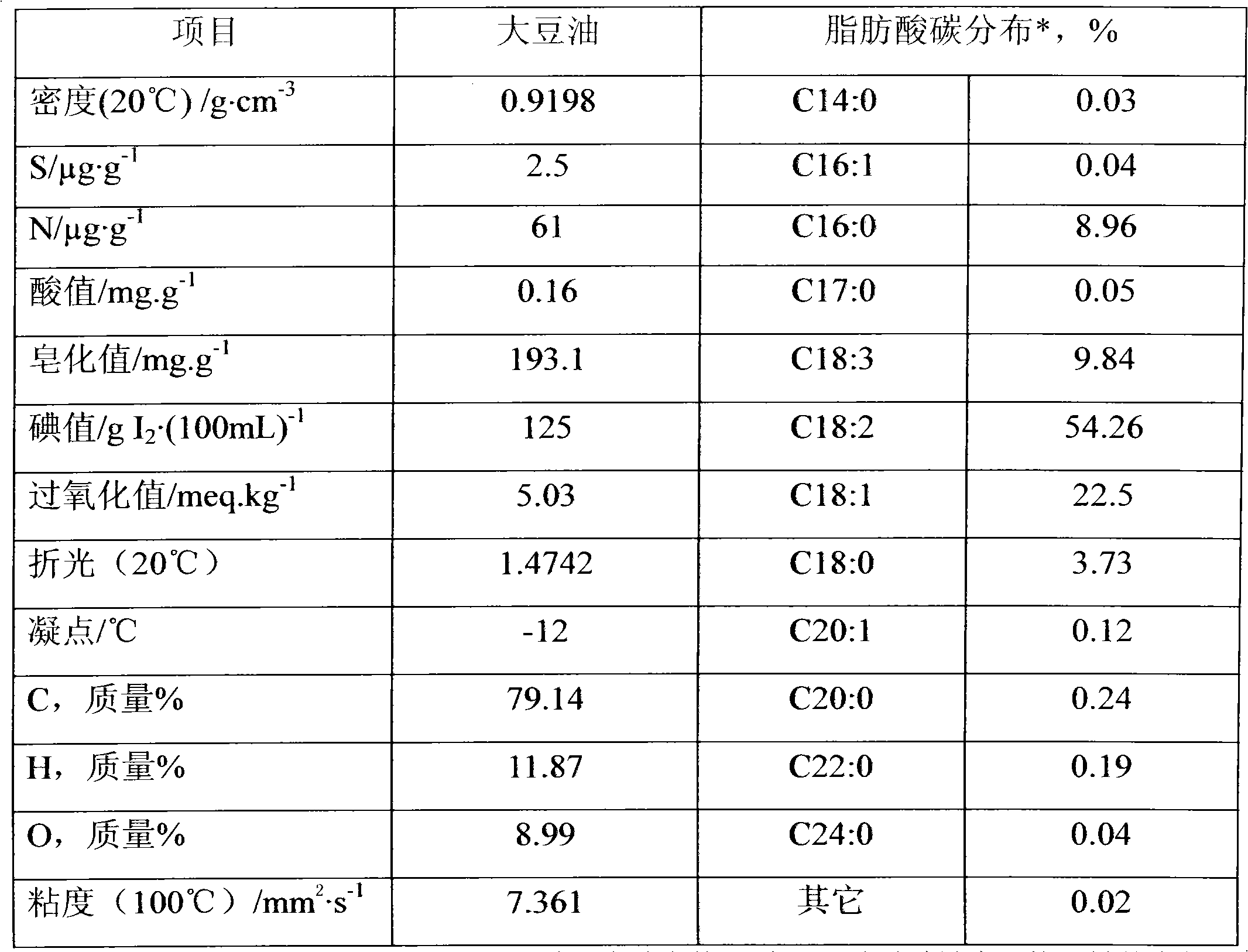

[0048] The animal and vegetable oil raw material used in the test is soybean oil. The properties of soybean oil and modified raw materials outside the device are listed in Table 2 and Table 3. The test conditions and test results are listed in Table 4-Table 6.

Embodiment 2

[0050] use figure 1 The process shown is different in that the raw material entering the hydro-upgrading unit does not include catalytic cracking diesel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com