Preparation method of mesoporous-microporous zeolite molecular sieve

A microporous zeolite and molecular sieve technology, applied in the field of molecular sieve synthesis and modification, can solve the problems of reducing zeolite catalytic activity, microporous crystal structure damage, low mesopore specific surface area, etc., and achieve BET surface area improvement, high mesopore specific surface area, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 30g of microporous mordenite and 2400mL of 0.30 mol / L NaOH solution in a beaker, stir at room temperature for 30min, transfer to a closed reaction kettle, add 75mL of methanol, treat at 60°C for 4h, filter and wash . Put the washed mordenite in a beaker, add 1500mL of 0.2mol / L hydrochloric acid solution, stir at room temperature for 20min, transfer to a water bath at 70°C for 3h, filter, wash, and dry in an oven at 110°C for 12h. The obtained sample number is CL1.

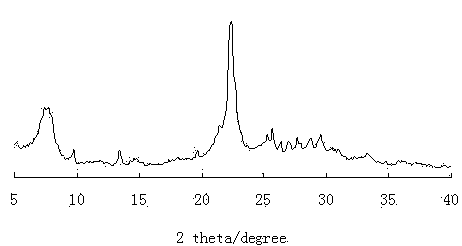

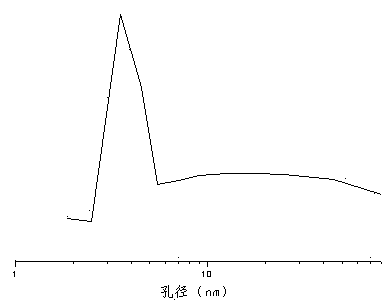

[0038] Depend on figure 1 It can be seen that the CL1 sample has the characteristic spectrum of mordenite and still maintains a good zeolite structure. Depend on image 3 It can be seen that after the modification treatment, there is an obvious concentration of mesopores in the microporous mordenite, and the most probable pore diameter is 3.5nm, indicating that after the treatment, a large number of mesoporous structures are formed in the mordenite.

Embodiment 2

[0040] Take 1 g of microporous ZSM-5 zeolite and 40 mL of 0.60 mol / L KOH solution in a beaker, stir at room temperature for 30 min, transfer to a closed reaction kettle, add 3 mL of ethanol, and treat at 80 °C for 3 h. Filter and wash. Put the washed ZSM-5 zeolite in a beaker, add 30mL of 0.2mol / L nitric acid solution, stir at room temperature for 20min, transfer to a water bath at 90°C for 2h, filter, wash, and dry in an oven at 110°C 12h, the obtained sample number is CL2.

Embodiment 3

[0042] Take 30 g of microporous β, 2100 mL of 0.50 mol / L NaOH solution in a beaker, stir at room temperature for 30 min; then transfer to a closed reaction kettle, add 150 mL of propanol, and treat at 100 ° C for 4 h; filter , Washing; put the washed zeolite beta into a beaker, add 1500mL of 0.8mol / L sulfuric acid solution, stir at room temperature for 30min, transfer to a water bath at 90°C for 3h, filter, wash, and place in an oven for 110 ℃ drying for 12h, the obtained sample number is CL3.

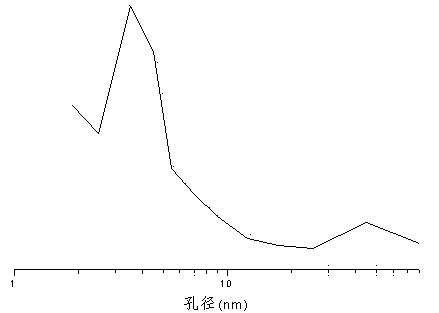

[0043] Depend on figure 2 It can be seen that the CL3 sample has the characteristic spectrum of zeolite beta and still maintains a good structure of zeolite beta. Depend on Figure 4 It can be seen that after the modification treatment, there is an obvious concentration of mesoporous pore diameters in the microporous zeolite β, and the most probable pore diameter is 3.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com