Fully automatic film sticking machine

A film laminating machine, fully automatic technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of poor dimensional accuracy of film cutting, poor position accuracy of protective film, poor position accuracy of film sticking, etc. High-precision size, high-precision film position, and the effect of cutting film edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

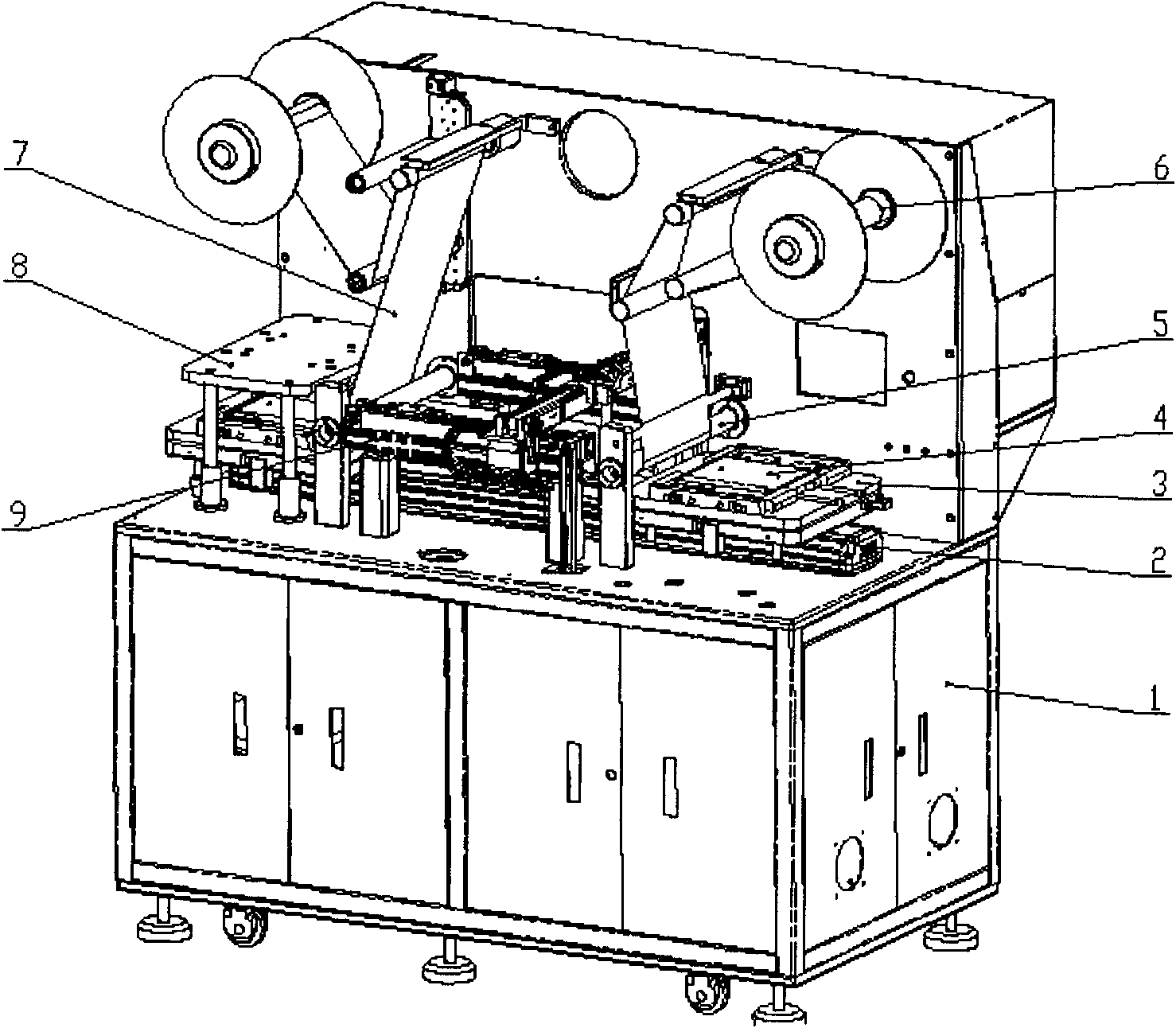

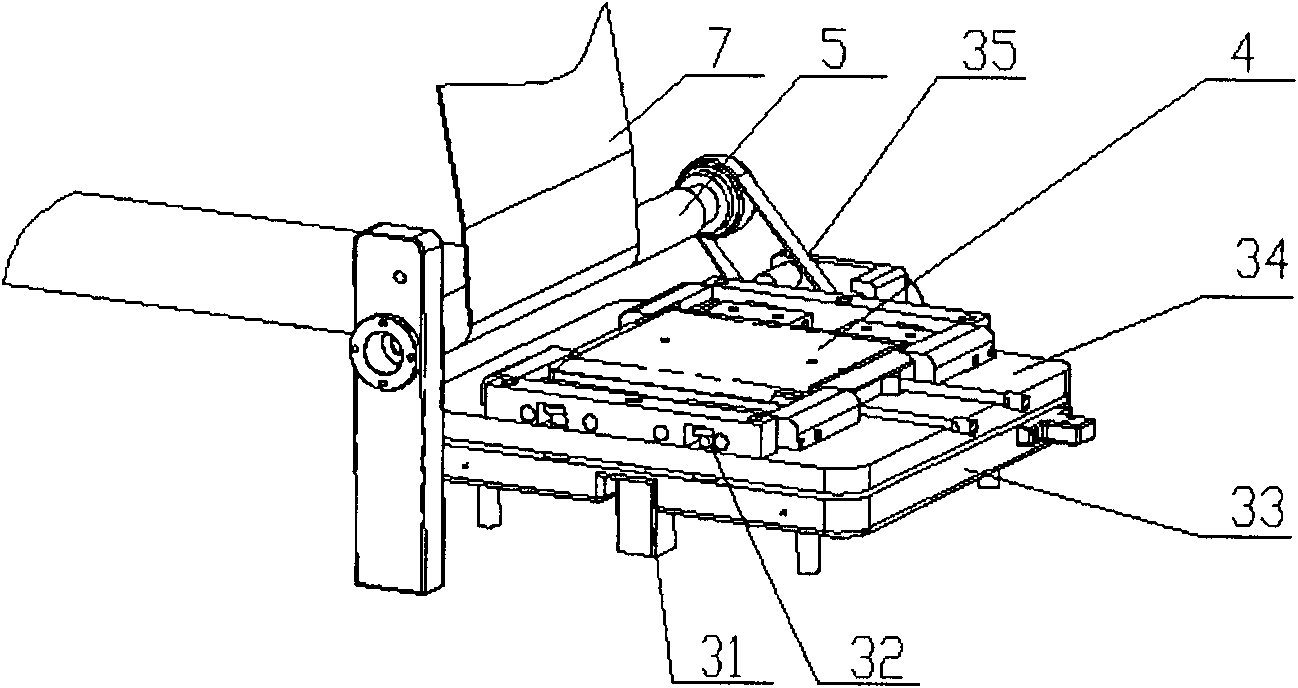

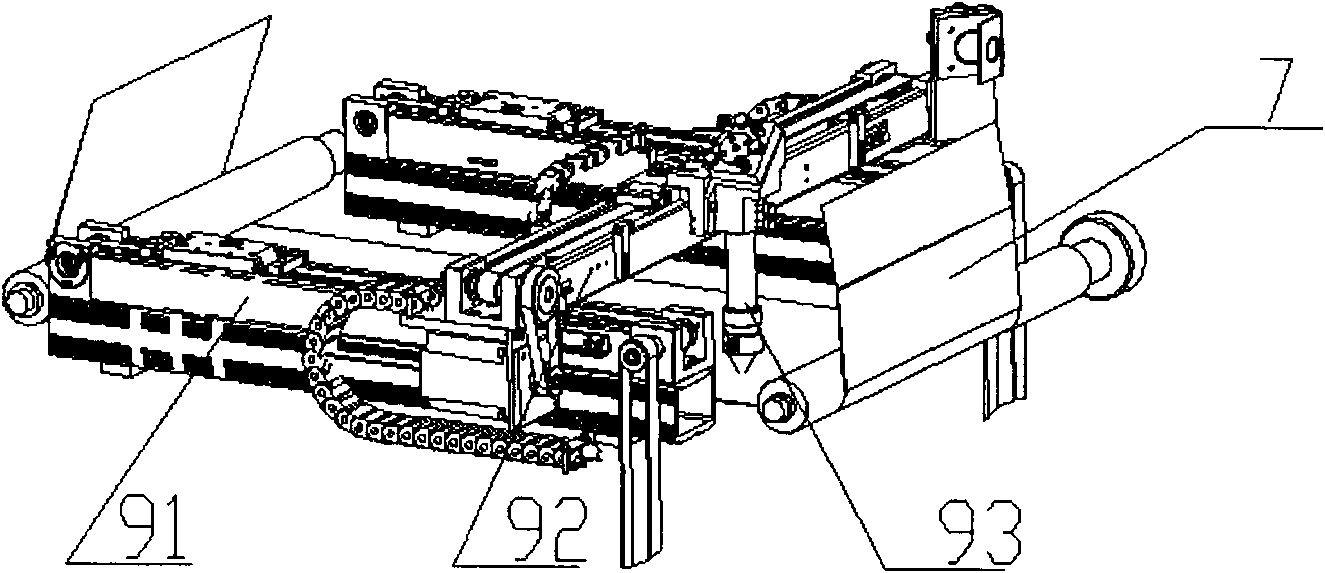

[0034] like figure 1 As shown, the present invention provides a fully automatic film laminating machine, including a body 1 and a transmission system 2 placed on the body 1, a product carrier 3, a pressure roller 5, a film cutting system 9, a film pressing system 8, and a film feeding system 6 And the control system placed in the body 1. The pasted product 4 is placed on the product carrier 3, and the product carrier 3 is fixed on the transmission system 2. The transmission system 2 is driven by a ball screw and a servo motor, and is driven by a control system to achieve precise positioning. The transmission system 2 drives the product carrier 3, and drives the pasted product 4 to move forward. When passing the pressure roller 5, the pressure roller 5 presses the protective film 7 onto the surface of the pasted p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com