Paper diaper

A diaper and paper technology, applied in the field of diapers, can solve the problems of easy formation of lumps, discomfort, poor urine absorption effect, etc., and achieve the effects of easy drainage and infiltration, strengthening the drainage effect, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

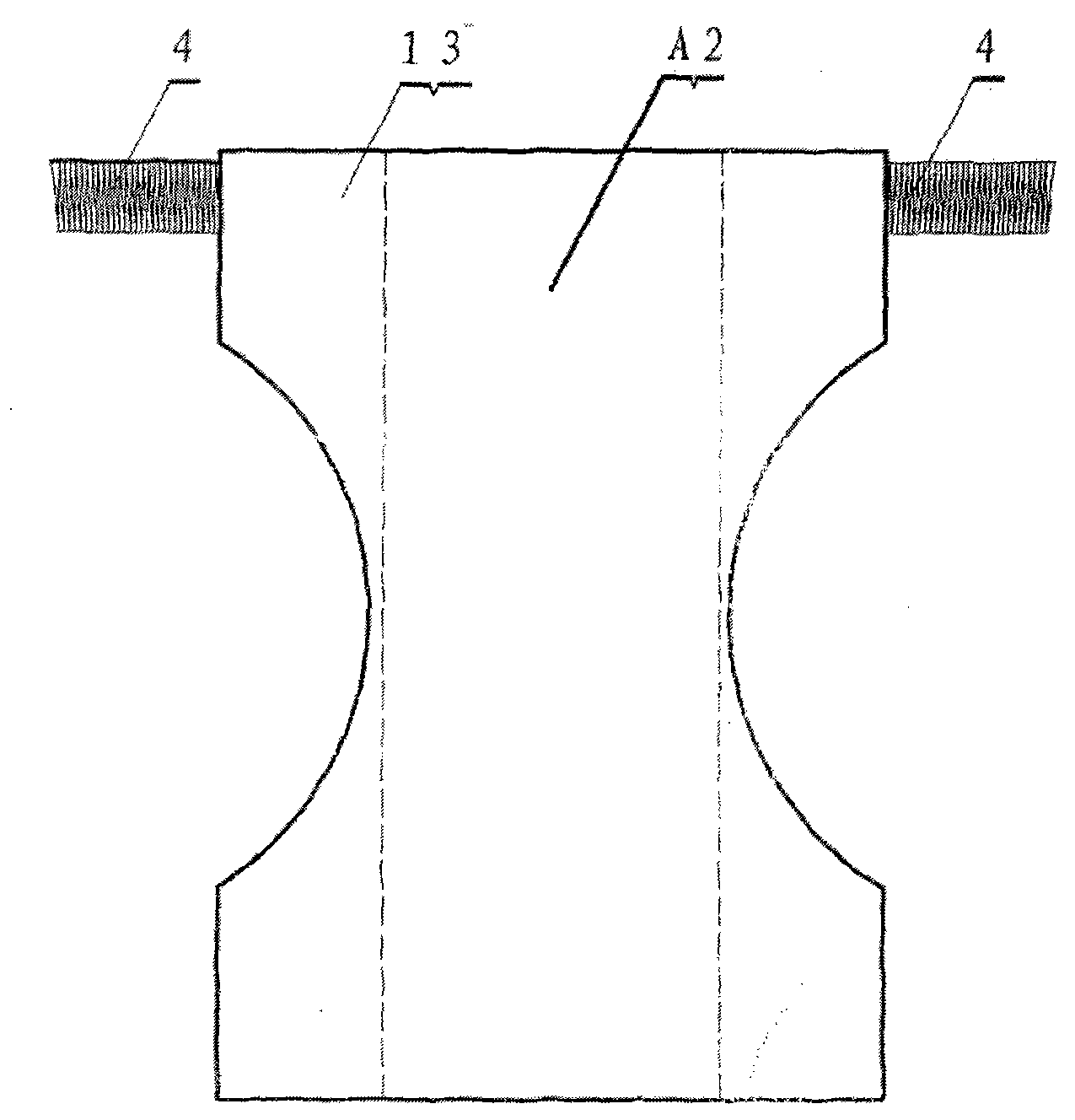

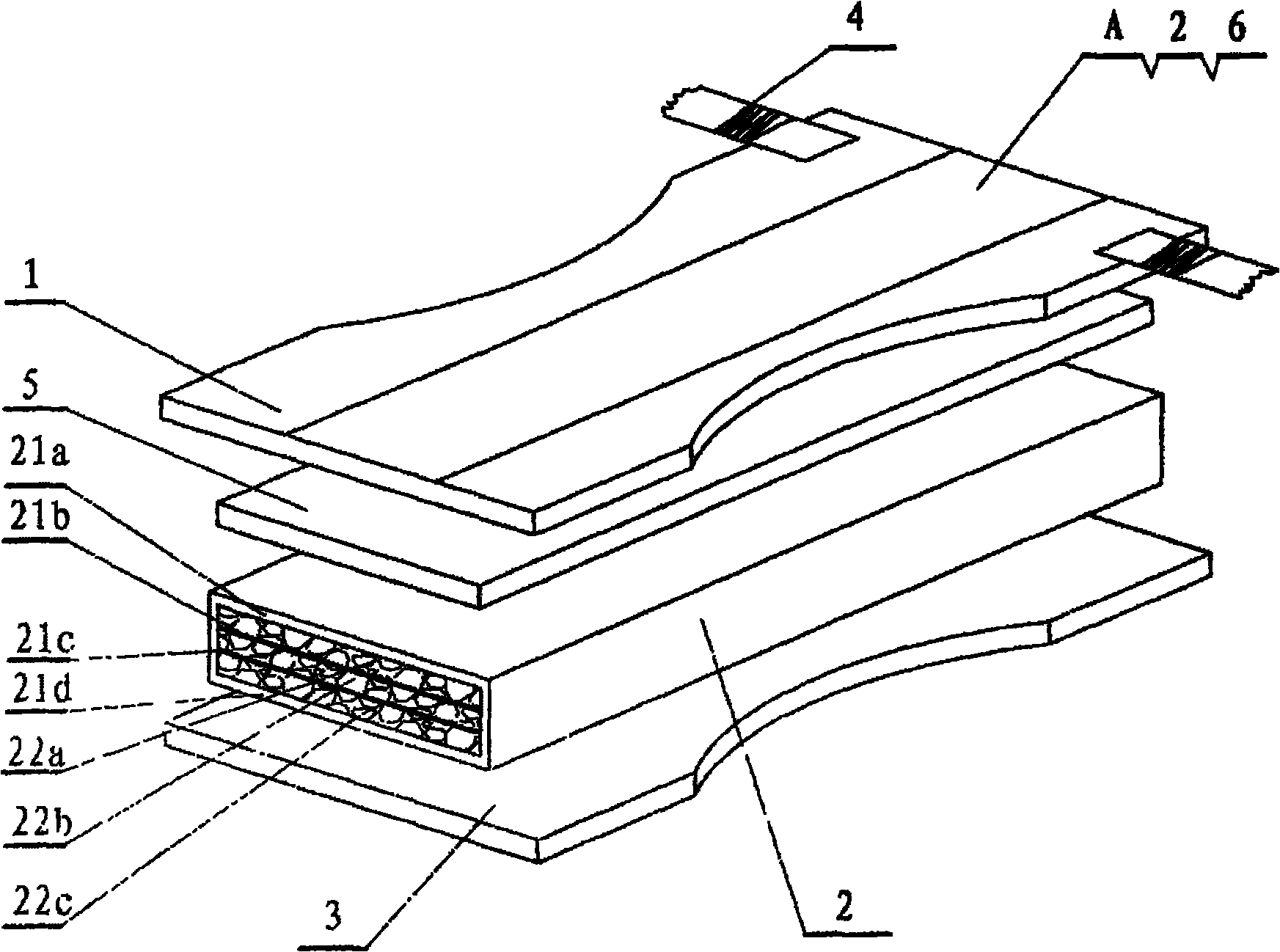

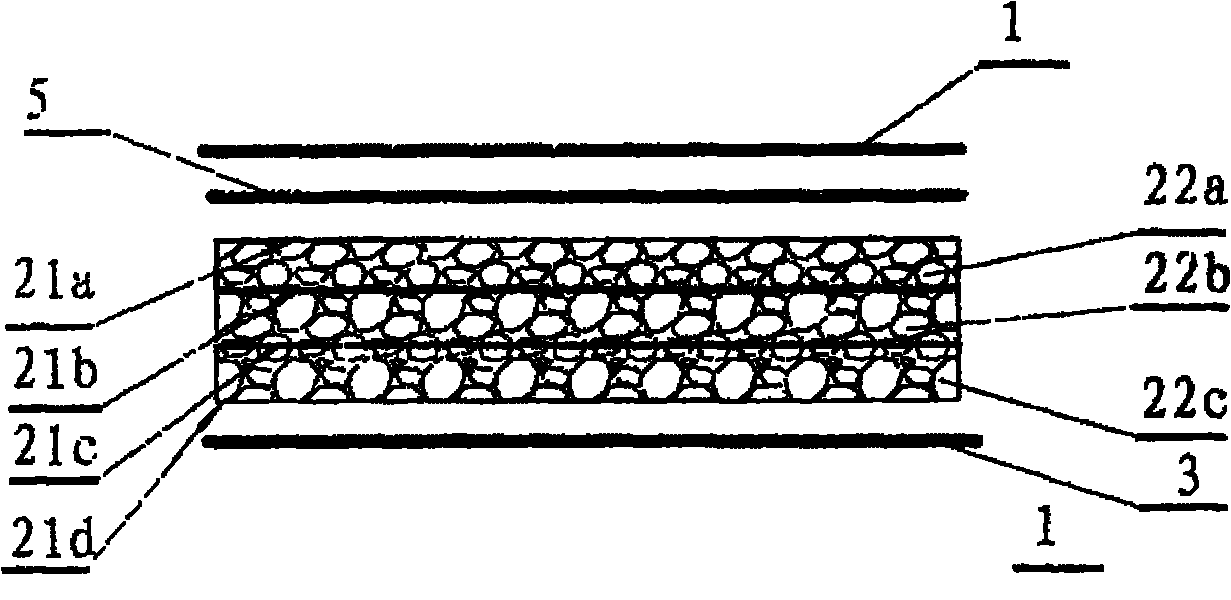

[0019] Such as figure 1 , figure 2 , image 3 As shown, the paper diaper of the present invention is composed of a water-permeable non-woven inner cover layer 1, a water-impermeable leak-proof outer cover layer 3, an absorbent core layer 2, and an enclosing connector 4, with a thickness of 1.8 mm to 2.2 mm, wherein the water-permeable A flow-guiding layer 5 is provided between the non-woven inner cover layer 1 and the absorbent core layer 2. The absorbent core layer 2 is a layered body in which a polymer water-absorbing resin layer is sandwiched between the spacer layers of dust-free paper, and each layer is connected along the periphery. Composed of connections, the absorbent core layer 2 is a seven-layer cross-laminated composite material body, followed by the uppermost layer of dust-free paper 21a, polymer water-absorbing resin layer 22a, dust-free paper 21b, polymer water-absorbing resin layer 22b, and dust-free paper 21c , Polymer absorbent resin layer 22c, dust-free p...

Embodiment 2

[0024] Such as Figure 4 , Figure 5 As shown in , the paper diaper of the present invention is composed of a water-permeable non-woven inner cover layer 1, an impermeable leak-proof outer cover layer 3, an absorbent core layer 2, and a surrounding connector 4, and the thickness is 1.5 mm to 1.9 mm. , wherein a flow-guiding layer 5 is provided between the water-permeable non-woven inner cover layer 1 and the absorbent core layer 2, and the absorbent core layer 2 is laminated with a polymer water-absorbent resin layer and a mixed layer composed of wood fiber and polymer water-absorbent resin A ten-layer cross-laminated composite material body with small white paper sandwiched and covered with small white paper, followed by the uppermost layer of small white paper 21a, polymer water-absorbent resin layer 22a, made of wood fiber and polymer water-absorbent resin. Composed of mixed layer 23a, small white paper 21b, polymer water-absorbing resin layer 22b, mixed layer 23b composed...

Embodiment 3

[0028] Such as Image 6 , Figure 7 As shown, the paper diaper of the present invention is composed of a water-permeable non-woven inner cover layer 1, an impermeable leak-proof outer cover layer 3, an absorbent core layer 2, and a surrounding connector 4, and the thickness is 1.7 mm to 2.0 mm. A functional layer 6 with antibacterial effect and a flow guide layer 5 are sequentially arranged between the inner cover layer 1 of the water-permeable non-woven fabric and the absorbent core layer 2, and the absorbent core layer 2 is composed of polymer water-absorbing resin layers 22a, 22b, 22c and non-woven fabrics. 21b, 21c are stacked alternately at intervals and covered with non-woven fabrics 21a and 21d, which is a seven-layer composite material body, and the distribution amount of polymer water-absorbing resin is 100g / m 2 , is heat-sealed on the non-woven fabric. The functional layer 6 with antibacterial effect is the bearing layer of the bacteriostatic composition known to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com