Pulse type vacuum generating device and cotton harvesting device and system

A vacuum generating device and cotton harvesting technology, which is applied to harvesters, picking machines, agricultural machinery and tools, etc., can solve the problems of poor cotton quality, limited cotton picking range, and insufficient vacuum suction, so as to prevent branches, leaves and other miscellaneous Effects of inhaling matter, improving picking speed, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

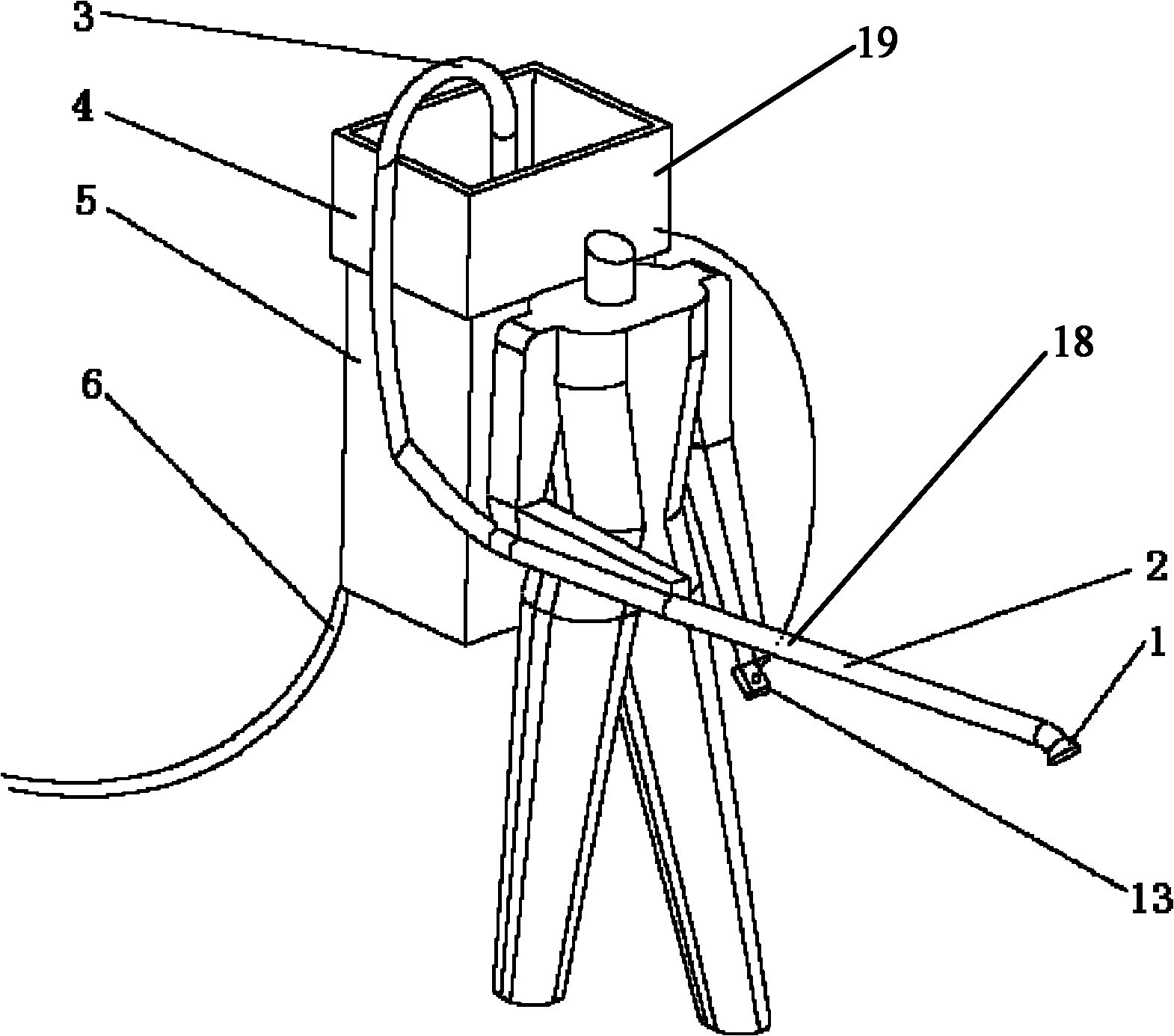

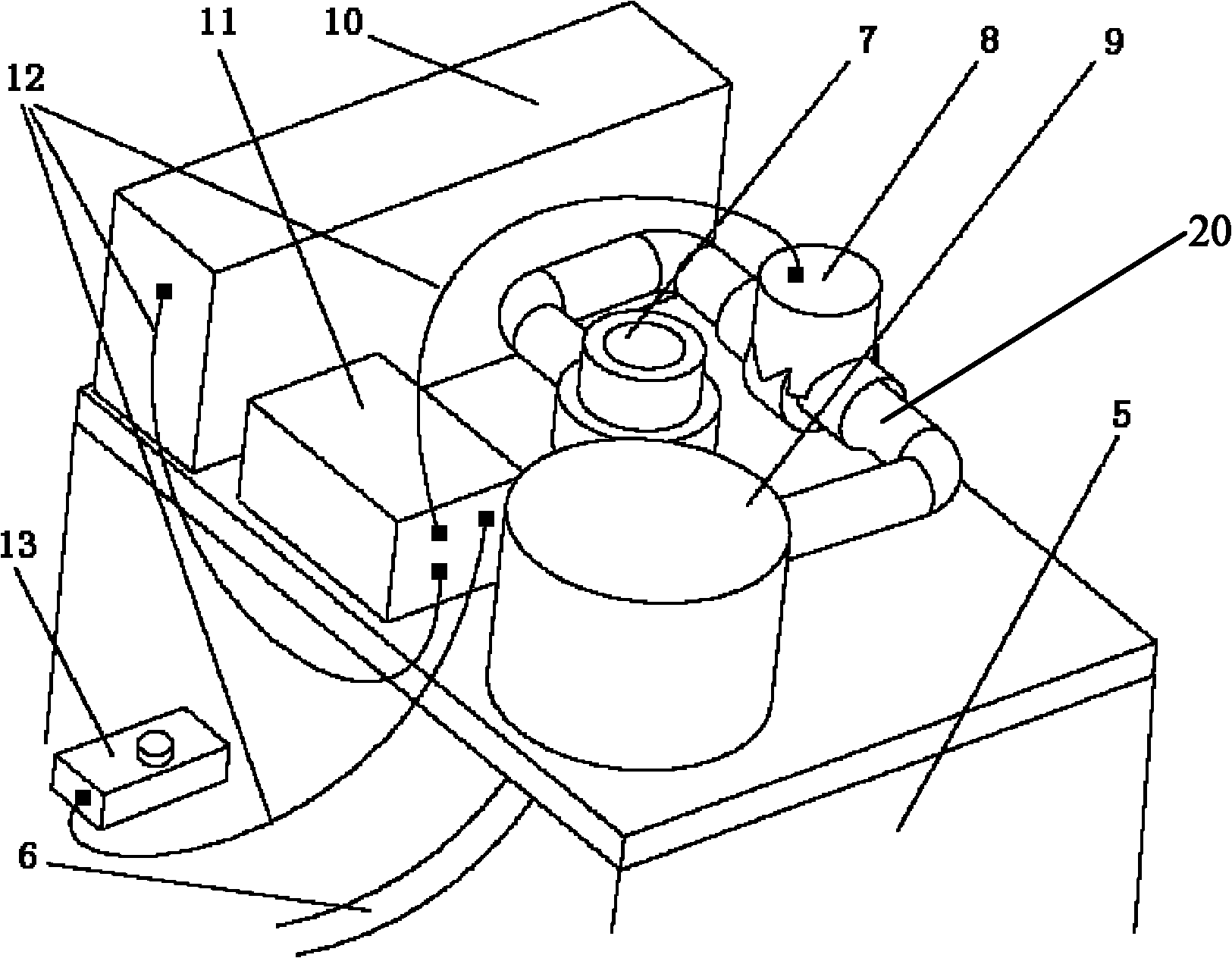

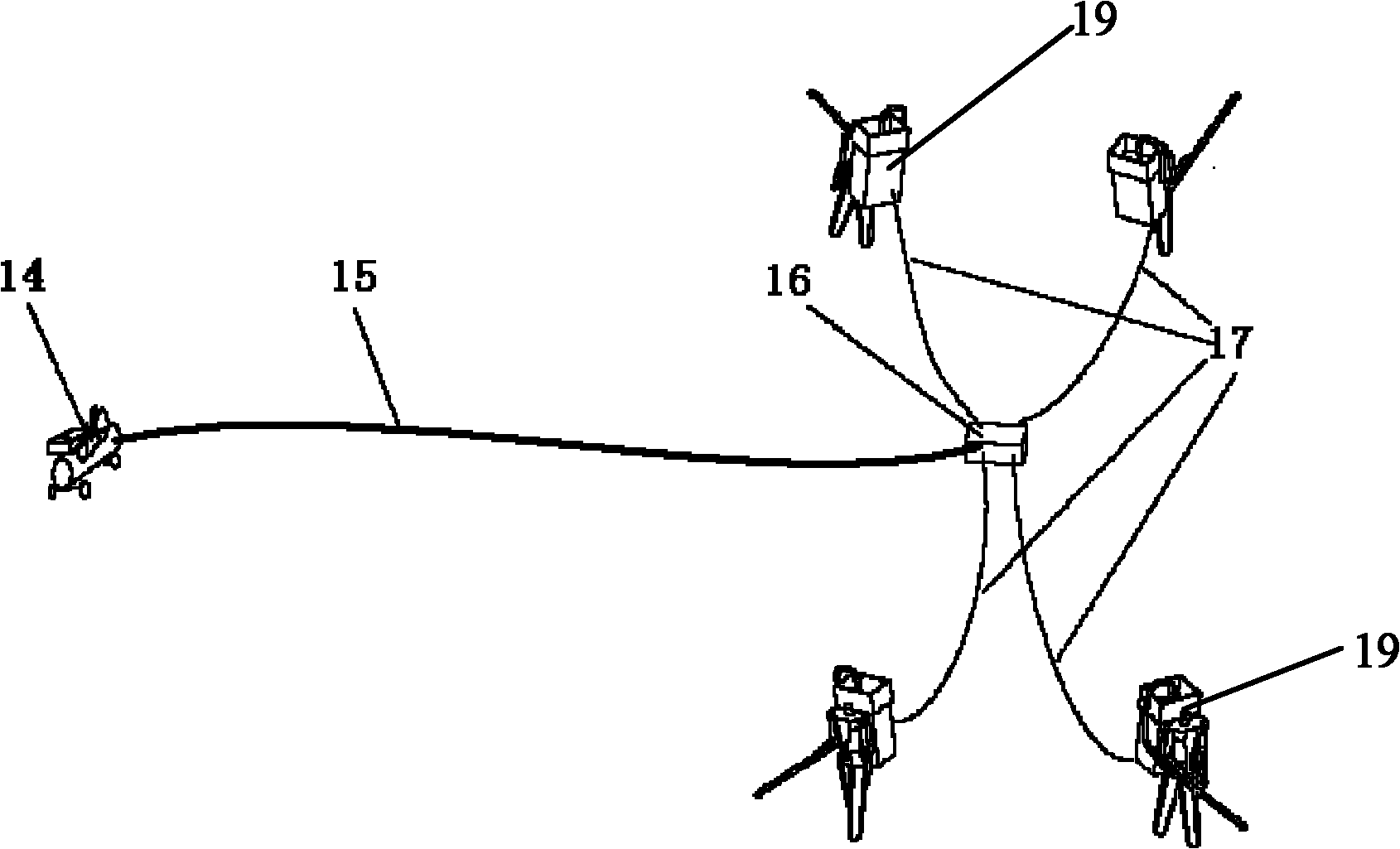

[0023] Such as figure 1 and figure 2 As shown, the cotton harvesting device 19 of this embodiment includes a pulsed vacuum generating device 4 and a cotton picking pipeline 18 . The pulsed vacuum generating device 4 includes a receiving device 9 for receiving compressed gas, an air pumping device 7 for generating vacuum pulses, and a converting device for converting the compressed gas flow into a pulsed gas flow, the receiving device 9, the converting device and the pumping device The gas device 7 is connected in sequence through the gas pipeline 20, and the cotton picking pipeline 18 communicates with the gas extraction device 7, and the gas extraction device 7 has a cotton outlet for outputting cotton bolls. When the cotton harvesting device is in use, the operator aligns the cotton picking pipe 18 with the cotton bolls and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com