Borehole compensated resistivity logging tool having an asymmetric antenna spacing

A resistivity, logging-while-drilling technology, which is applied in electrical/magnetic detection for logging records, borehole/well components, and electromagnetic wave detection, etc., can solve problems such as calibration errors, achieve accurate drilling compensation, The effect of total tool length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

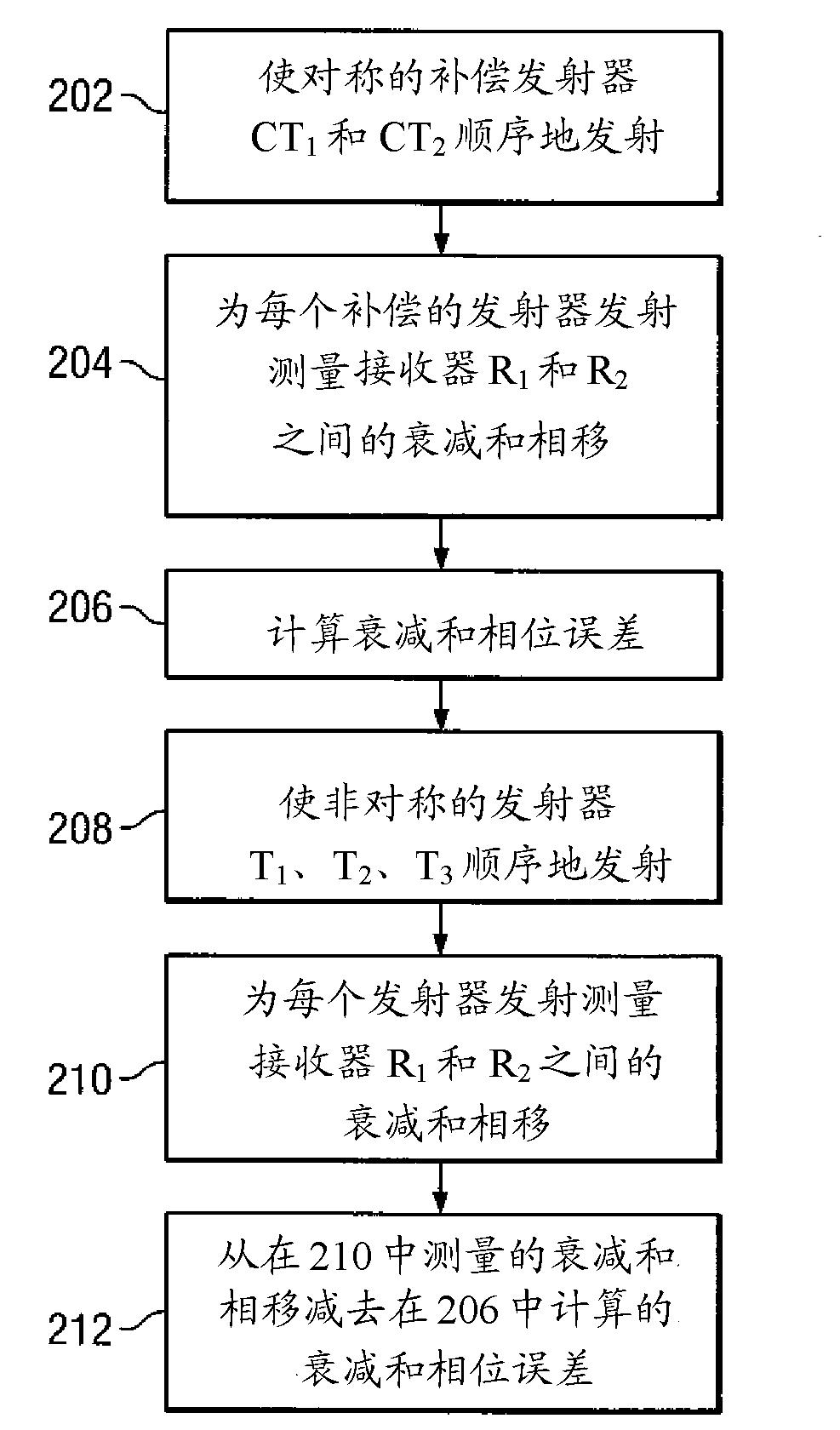

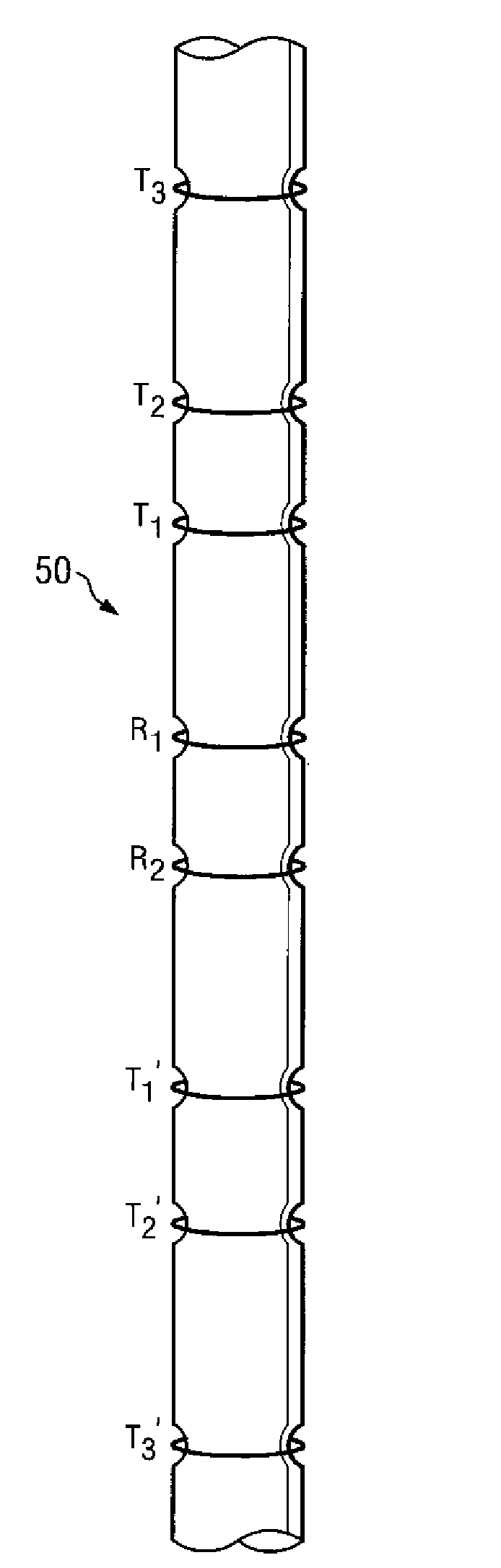

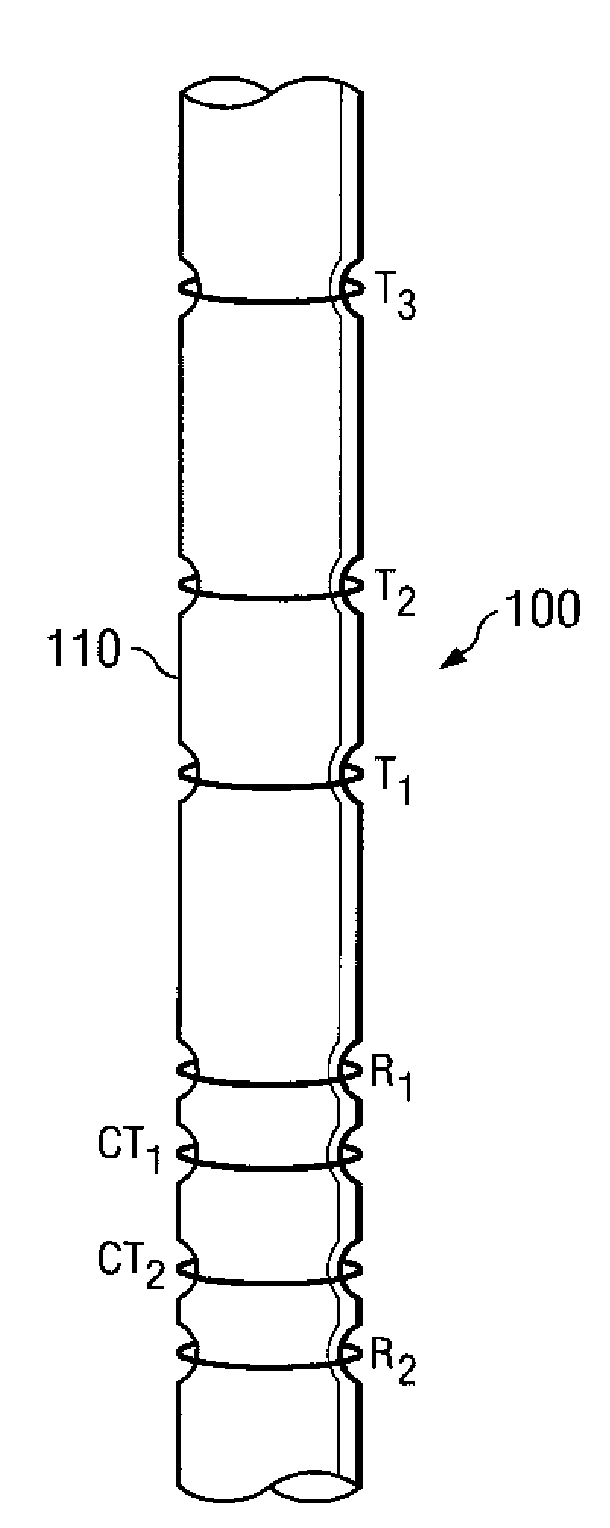

[0019] figure 2 An exemplary embodiment of a LWD resistivity tool 100 according to the present invention is shown. The resistivity tool 100 includes a plurality of spaced apart transmitters T disposed about a tool body 110 1 , T 2 and T 3 and a pair of spaced receivers R 1 and R 2 . Transmitter T 1 , T 2 and T 3 can be considered asymmetric since they are deployed on the receiver pair R 1 and R 2 on one axial side of and since there is no corresponding symmetrical transmitter deployed on the opposite axial side of the receiver. In contrast to the prior art resistivity tool 50 shown in FIG. 1, the present invention does not include a second set of symmetrical emitters. The resistivity tool 100 also includes a pair of symmetrical compensation transmitters CT 1 and CT 2 . exist figure 2 In the exemplary embodiment shown, these compensating transmitters CT 1 and CT 2 Axially deployed on the receiver pair R 1 and R 2 between. Although the invention is not limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com