Liquid-cooled heat dissipation system

A cooling system and liquid cooling technology, applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the overheating of electronic components, reduce the heat exchange efficiency between liquid and electronic components, and affect the liquid-cooled cooling system. Heat dissipation efficiency and other issues to achieve the effect of improving heat dissipation efficiency and avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

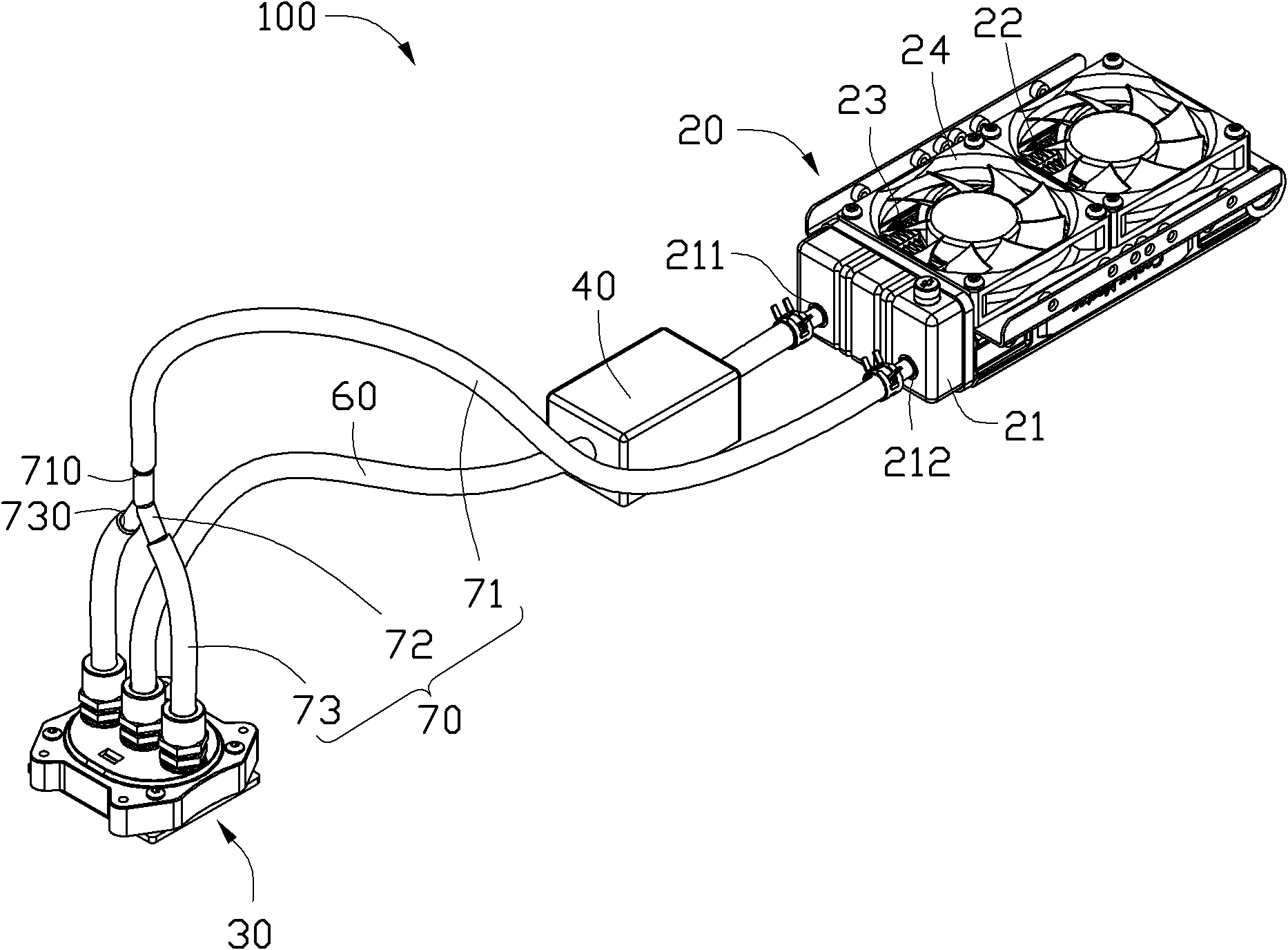

[0017] Please refer to figure 1 , shows a liquid-cooled heat dissipation system 100 in an embodiment of the present invention, the liquid-cooled heat dissipation system 100 includes a heat dissipation element 20, a heat absorption element 30, a drive pump 40, the heat absorption element 30 and the heat dissipation element 20 is connected to a water inlet pipe 60 and a water outlet pipe 70.

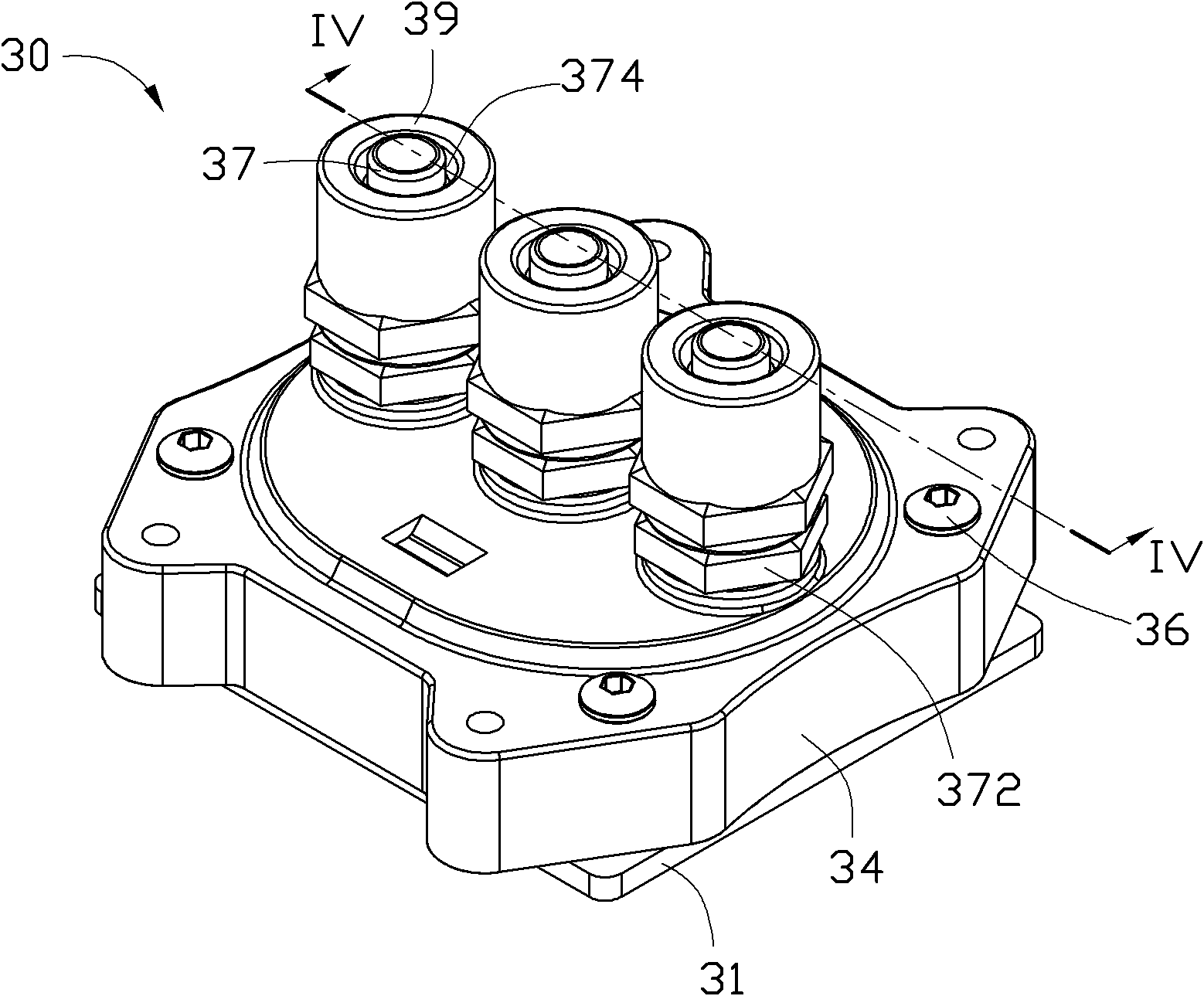

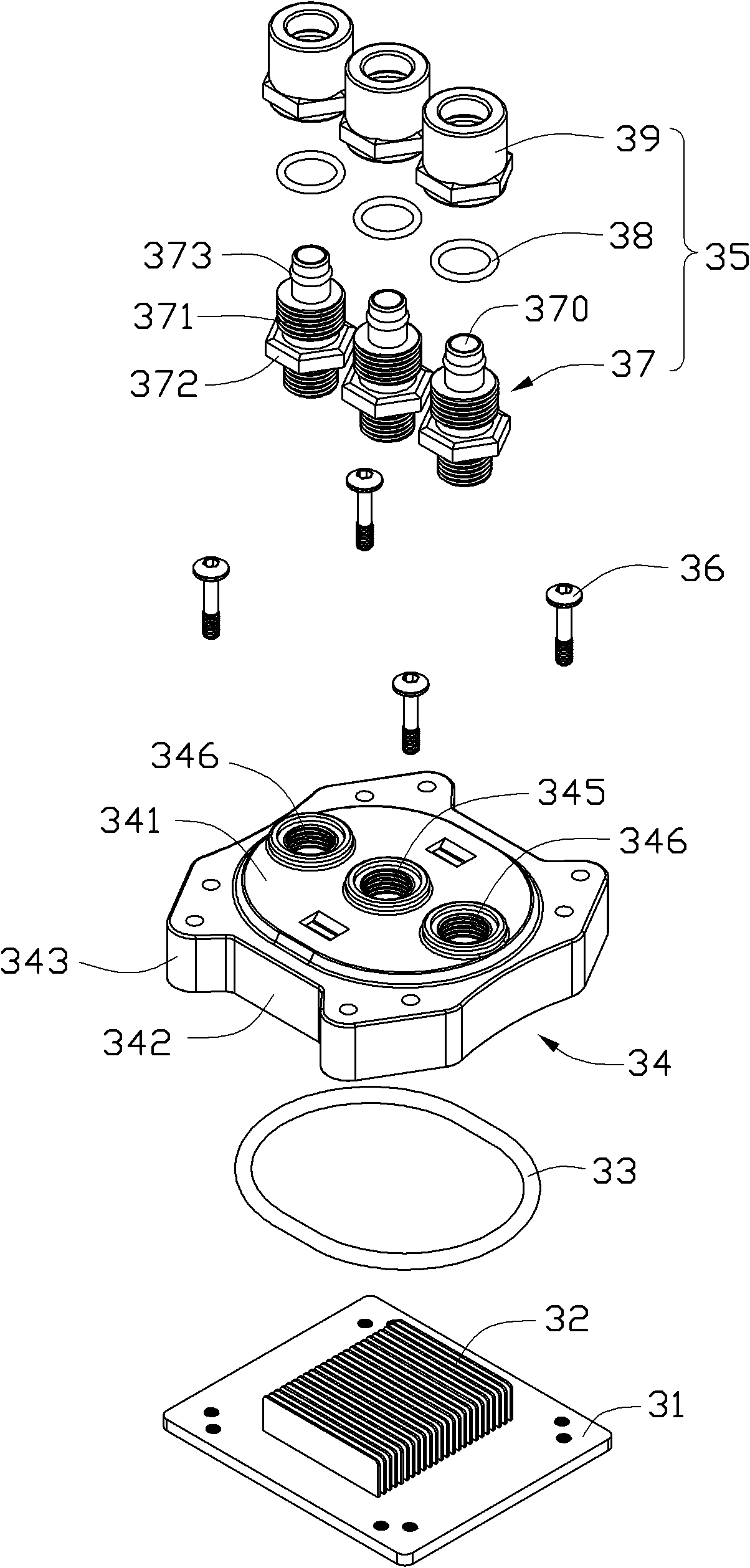

[0018] The heat absorbing element 30 and the heating electronic element 80 ( Figure 4 ), such as the CPU is in close contact, so as to absorb the heat generated by the electronic components 80 in time. Please also see figure 2 and image 3 , the heat absorbing element 30 includes a bottom plate 31 , a radiator 32 , a sealing ring 33 , a cover 34 and three connecting pieces 35 .

[0019] The bottom plate 31 is usually made of a material with better thermal conductivity, such as copper. The cover 34 includes a circular top wall 341 , a side wall 342 extending downward from a periphery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com