Redundant metal filling method for integrated circuit layout

A redundant metal, integrated circuit technology, applied in the fields of electrical digital data processing, instrumentation, calculation, etc., can solve the problem of increasing interconnect capacitance, signal delay, chroma, brightness, interference, noise, energy consumption, increase in calculation amount, and increase the difficulty of design. and other problems to achieve the effect of reducing the impact of convergence and signal integrity, reducing the impact and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] In integrated circuit manufacturing and layout design, the problem that redundant metals increase the coupling capacitance of signal lines is often encountered.

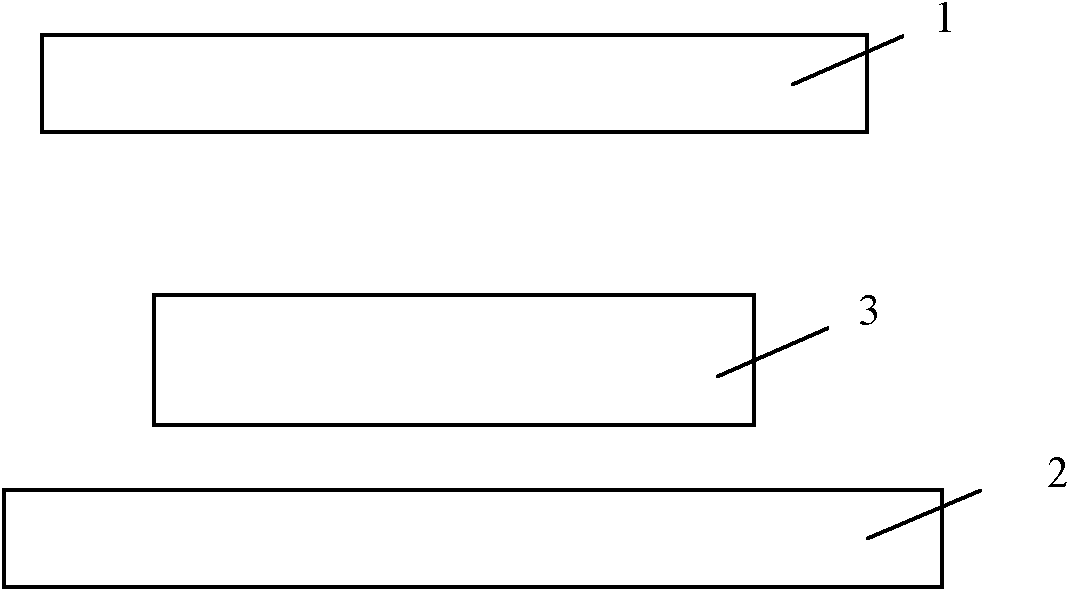

[0017] Such as figure 1 As shown, a redundant metal 3 with a defined area is filled between the two parallel signal lines 1 and 2 . Since the filling position and filling shape of the redundant metal 3 are not considered, the redundant metal has a great influence on the coupling capacitance between the two signal lines.

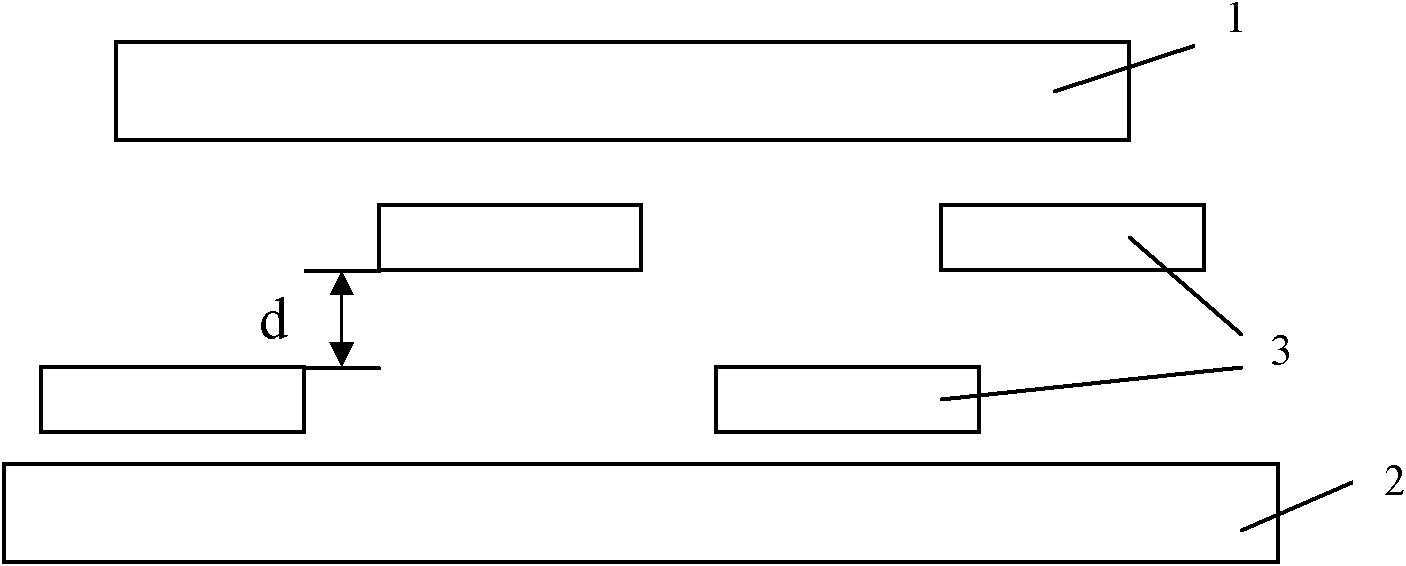

[0018] The filling method of the redundant metal in the layout of the integrated circuit disclosed by the present invention fully considers the filling position and filling shape of the redundant metal between the signal lines. In order to achieve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com