Method for processing heavy material by using up-flow reactor system

A technology for reactor systems and heavy raw materials, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as complex design and manufacture, uneven fluid distribution, and easy hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

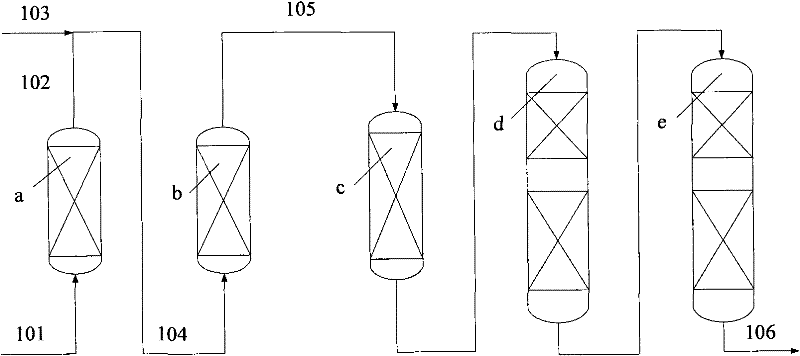

[0034] use figure 1 The process flow shown has two upflow fixed-bed reactors connected in series. The mixture of residual oil raw material and hydrogen enters two series-connected upflow fixed-bed reactors with a single catalyst bed through the inlet pipe 101, and the products of removing part of sulfur, nitrogen, carbon residue and metals are drawn out from the pipe 105.

[0035] The catalyst used is an upflow catalyst developed by the Petrochemical Science Research Institute. Catalysts were produced by Catalyst Changling Branch of China Petroleum & Chemical Corporation. The loading situation of the catalyst in each reactor is:

[0036] The catalyst in the a reactor is RG-10A, RUF-1B, RUF-1C from bottom to top; The loading volume of catalyst is 500ml, and the loading volume ratio of catalyst is 10:60:30.

[0037] The catalyst in the b reactor is RUF-1C and RUF-2B from bottom to top; the loading volume of the catalyst is 500ml, and the loading volume ratio of the catalyst i...

Embodiment 2

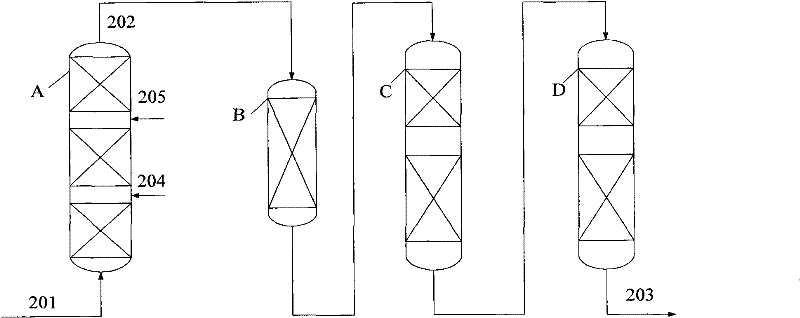

[0042] according to figure 2 The process flow shown is composed of two serial fixed bed flow reactors a, b and three downflow fixed bed hydroprocessing reactors c, d and e. The mixture of vacuum residue, vacuum gas oil and hydrogen is sent to two series-connected upflow fixed-bed reactors a and b through pipe 101. The mostly metal-depleted effluent enters the top of conventional hydrotreating reactor c via line 105, and then enters reactors d and e for further removal of carbon, sulfur and nitrogen. The hydrotreated product can be used as feedstock for further processes such as hydrocracking or FCC.

[0043] The catalyst used is a catalyst developed by the Petrochemical Science Research Institute. Catalysts were produced by Catalyst Changling Branch of China Petroleum & Chemical Corporation. The loading situation of the catalyst in each reactor is:

[0044] The catalyst in the a reactor is RG-10A, RUF-1B, RUF-1C from bottom to top; The loading volume of catalyst is 500ml,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com