Preparation method of ultrahigh molecular weight sulfonic acid-type polyacrylamide

A polyacrylamide, ultra-high molecular weight technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as low molecular weight, and achieve the effects of simple reaction operation, reduction of polymer dosage, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

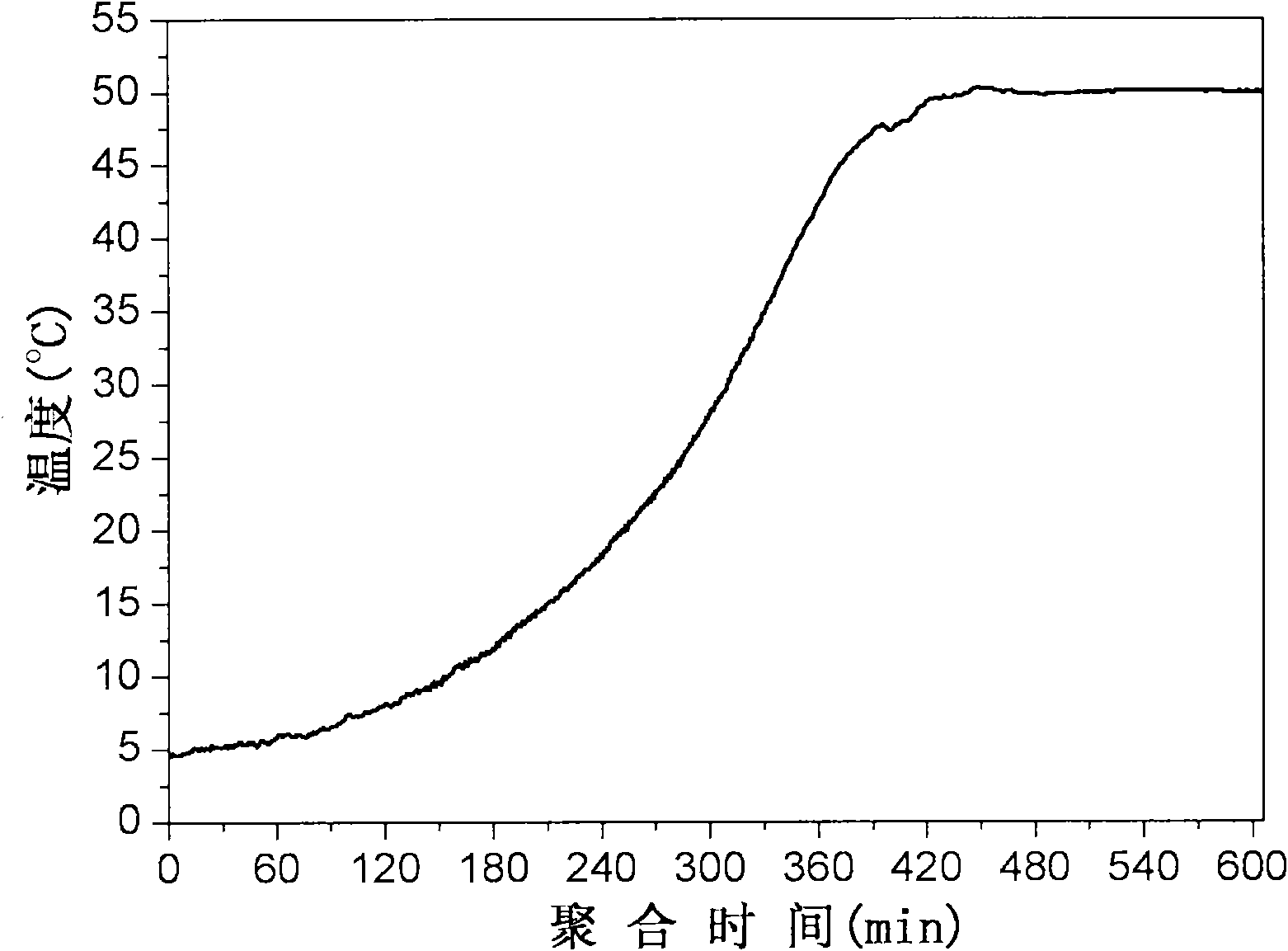

[0048] Add 370g (1.7857mol) of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 380g (5.346mol) of acrylamide (AM) into a 5000ml beaker, add 1940g of deionized water, stir to make The body was completely dissolved, and then slowly added 285.8 g (1.786 mol NaOH) of 25% NaOH aqueous solution and stirred evenly. Add 5.0 g of 1% EDTA aqueous solution, 6.0 g of 1% azobisisobutylamidine hydrochloride aqueous solution, 0.3 g of urea, and 1% of bifunctional peroxide 2,5-dimethyl Base-2,5-dihydroperoxyhexane 6.0g, stir well to make it evenly mixed. Adjust the pH of the system to 8.0 with 1% sodium hydroxide or 1% hydrochloric acid aqueous solution. Put it in a refrigerator or a low-temperature bath to cool the material to 4°C, then pour the cooled solution into a 4700ml Dewar flask to reduce the heat exchange between the system and the outside world, and add 1% Sodium bisulfite aqueous solution 6.0g, and continue nitrogen deoxygenation for 10 minutes. The reactor is sealed, and ...

Embodiment 2

[0050] 416g (2.008mol) of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 334g (4.6989mol) of acrylamide (AM) were added to a 5000ml beaker, and 1906g of deionized water was added, and stirred to make a single The body was completely dissolved, and then slowly added 25% NaOH aqueous solution 321g (2.006mol NaOH) and stirred evenly. Add 5.0 g of 1% EDTA aqueous solution, 6.0 g of 1% azobisisobutylamidine hydrochloride aqueous solution, 0.3 g of urea, and 1% of bifunctional peroxide 2,5-dimethyl Base-2,5-dihydroperoxyhexane 6.0g, stir well to make it evenly mixed. Adjust the pH of the system to 8.0 with 1% sodium hydroxide or 1% hydrochloric acid aqueous solution. Put it in a refrigerator or a low-temperature bath to cool the material to 4°C, then pour the cooled solution into a 4700ml Dewar flask to reduce the heat exchange between the system and the outside world, and add 1% Sodium bisulfite aqueous solution 6.0g, and continue nitrogen deoxygenation for 10 minutes. The...

Embodiment 3

[0052] Add 495g (2.3890mol) of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 255g (3.5875mol) of acrylamide (AM) into a 5000ml beaker, add 1844g of deionized water, stir to make The body was completely dissolved, and then 382.2 g (2.389 mol NaOH) of 25% NaOH aqueous solution was slowly added and stirred evenly. Add 5.0 g of 1% EDTA aqueous solution, 6.0 g of 1% azobisisobutylamidine hydrochloride aqueous solution, 0.3 g of urea, and 1% of bifunctional peroxide 2,5-dimethyl Base-2,5-dihydroperoxyhexane 6.0g, stir well to make it evenly mixed. Adjust the pH of the system to 8.0 with 1% sodium hydroxide or 1% hydrochloric acid aqueous solution. Put it in a refrigerator or a low-temperature bath to cool the material to 4°C, then pour the cooled solution into a 4700ml Dewar flask to reduce the heat exchange between the system and the outside world, and add 1% Sodium bisulfite aqueous solution 6.0g, and continue nitrogen deoxygenation for 10 minutes. The reactor is sealed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com