Preparation method of olefin polymerization catalyst component slurry

An olefin polymerization and catalyst technology, which is applied in the field of preparation of olefin polymerization catalyst slurry, can solve the problems of large surface energy, difficulty in stirring and dispersing dry powder particles uniformly, and fast sedimentation speed of slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

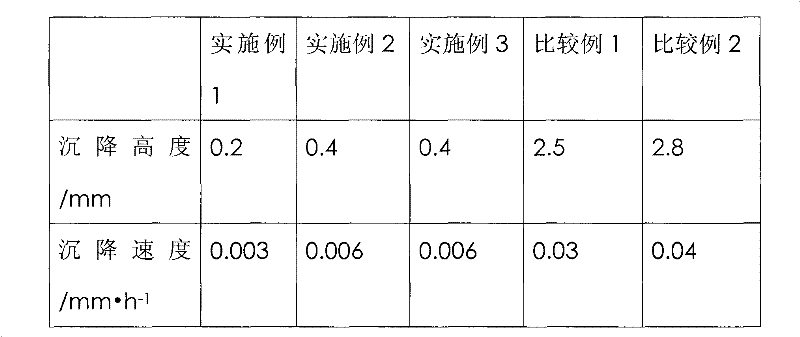

Embodiment 1

[0021] The catalyst component was prepared according to the method in Example 1 of patent CN85100997, except that the catalyst component was washed with hexane without vacuum drying, and 30 ml of hexane was added to prepare a suspension. Prepared so many times to obtain 500 ml of suspension.

[0022] In a dry 250ml round-bottomed flask, add 28 grams of white oil, then add 90 milliliters of the above-mentioned suspension, and carry out vacuum drying under stirring for 6 hours, and the temperature of the water bath is 50 ° C. When the drying is carried out for 4 hours, carry out ultrasonication for 1 Hours, ultrasonic frequency 50HZ. Then get 20 milliliters of catalyst slurry and inject in 25 milliliters of scaled glass tubes, read the height of the supernatant after standing for 72 hours, calculate the sedimentation velocity.

Embodiment 2

[0024] The catalyst component was prepared according to the method in Example 1 of patent CN85100997, except that the catalyst component was washed with hexane without vacuum drying, and 30 ml of hexane was added to prepare a suspension. Prepared so many times to obtain 500 ml of suspension.

[0025] In a dry 250ml round-bottomed flask, add 28 grams of white oil, then add 90 milliliters of the above suspension, and carry out vacuum drying under stirring for 6 hours, the temperature of the water bath is 40 ° C, when the drying is carried out for 4 hours, ultrasonic for 1 hour , Ultrasonic frequency 50HZ. Then get 20 milliliters of catalyst slurry and inject in 25 milliliters of scaled glass tubes, read the height of the supernatant after standing for 72 hours, calculate the sedimentation velocity.

Embodiment 3

[0027] The catalyst component was prepared according to the method in Example 1 of patent CN85100997, except that the catalyst component was washed with hexane without vacuum drying, and 30 ml of hexane was added to prepare a suspension. Prepared so many times to obtain 500 ml of suspension.

[0028] In a dry 250ml round-bottomed flask, add 28 grams of white oil, then add 90 milliliters of the above-mentioned suspension, and carry out vacuum drying under stirring for 6 hours, and the temperature of the water bath is 50 ° C. When the drying is carried out for 4 hours, carry out ultrasonication for 1 Hours, ultrasonic frequency 70HZ. Then get 20 milliliters of catalyst slurry and inject in 25 milliliters of scaled glass tubes, read the height of the supernatant after standing for 72 hours, calculate the sedimentation velocity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com