Desalination method by membrane vaporization absorption

A desalination and absorbent technology, applied in chemical instruments and methods, general water supply conservation, water/sewage multi-stage treatment, etc. High yield, comprehensive utilization, and reduction of concentrated water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

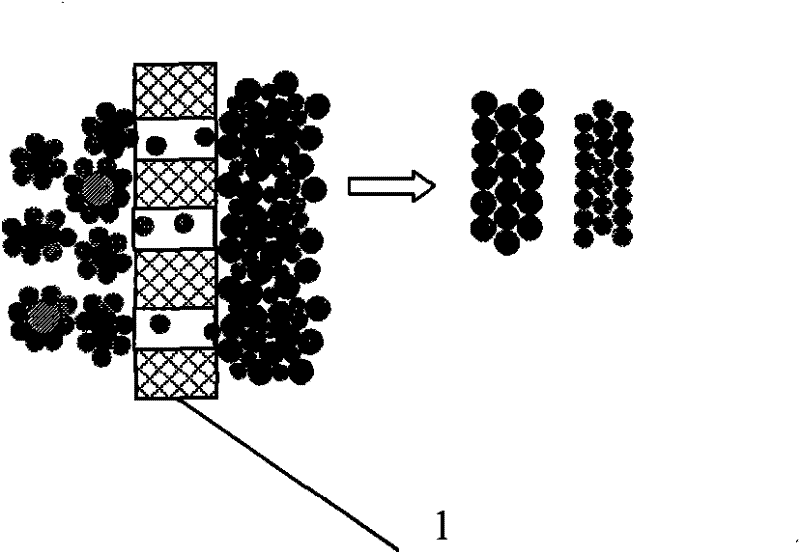

Method used

Image

Examples

Embodiment 1

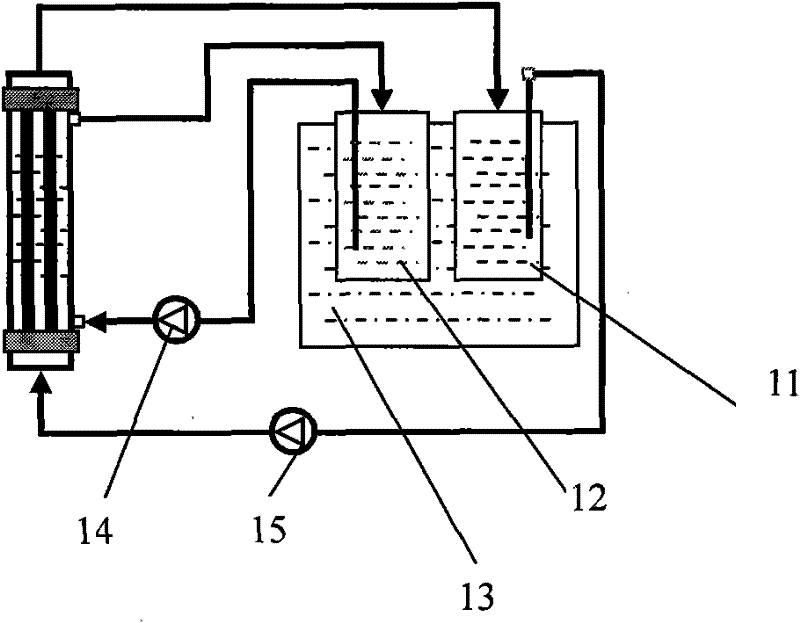

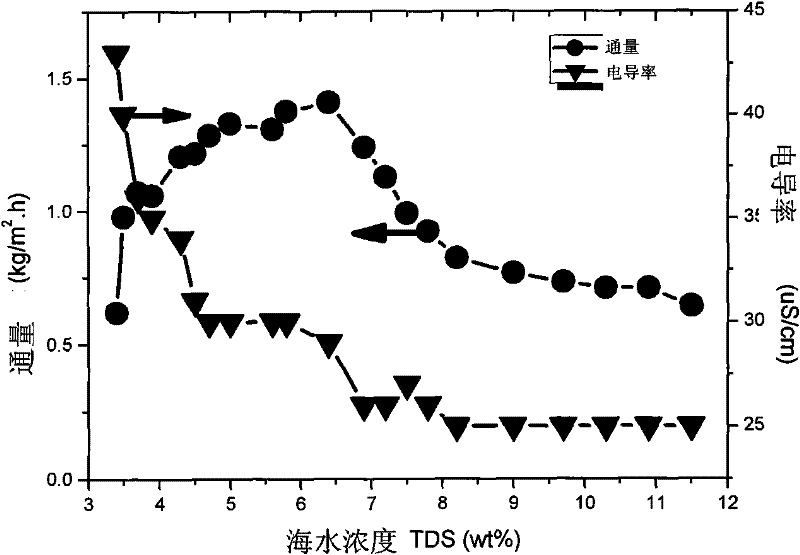

[0062] According to the white granulated sugar of 1.2 parts quality and the pure water of 1 part quality, prepare 54.5wt% white granulated sugar solution as absorbent, the initial conductivity of white granulated sugar absorbent is 44 μ S / cm, and salt water is seawater near Tianjin, TDS (total dissolved in water The total dissolved solids (TDS for short) is 3.3wt%. The absorbent volume is 3 liters, the seawater volume is 500ml, and the membrane module material is a hydrophobic polyvinylidene fluoride hollow fiber membrane with a membrane area of 0.053m 2 . Such as figure 2 , a water bath 13 is provided, and a sea water tank 11 and a white sugar absorbent tank 12 are arranged in the water bath 13 . First pass through the water bath 13, heat the seawater and white sugar absorbent to 75°C, then pump the seawater into the tube side of the hollow fiber membrane module through the seawater pump 15, and then pass the white sugar absorbent through the absorbent pump 14 Pump into ...

Embodiment 2

[0065] According to 2 parts of quality glucose (analytical pure) and 1 part of quality of pure water, prepare 66.7wt% glucose aqueous solution as absorbent, the initial conductivity of glucose absorbent is 5.5μS / cm, the salt water is Tianjin offshore seawater, TDS is 3.3 wt%. Absorbent volume is 3 liters, and seawater volume is 1000ml, all the same with embodiment 1.

[0066] Such as Figure 4 , as the absorbent is diluted by the pure water passing through the membrane, glucose powder is continuously added to the absorbent during the process to keep the concentration of the absorbent constant. When the seawater TDS is concentrated 11.8 times from 3.3wt% to 29.7wt%, the membrane flux is from the initial 1.46kg / m 2 .h gradually reduced to 0.11kg / m 2 .h, the water production rate of seawater reached 92%.

Embodiment 3

[0068] Separation is carried out by utilizing the solubility difference of pure water in the absorbent at different temperatures. Such as using butanol, DOP (dioctyl phthalate) and other absorbents, the process is as follows Figure 5 . After the absorption liquid is heated, it enters the tube side of the membrane module, and the seawater is heated by the heat exchanger and enters the shell side of the membrane module. In the membrane module, after the absorbent absorbs water molecules, it is discharged into the heat exchanger as a heat source, and the absorbent after heat exchange By cooling and stratifying, fresh water is produced. Since part of the absorbent can also be dissolved in water, the produced water is an aqueous solution of the absorbent, which requires secondary separation to remove the absorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com