Split type inverted wedge type power chuck for machine

A chuck and split technology, which is applied in the field of machine-used split flip-wedge power chucks, can solve the problems of reduced service life of the chuck, wear of the transmission part, and increased part size, and achieve high automatic centering accuracy , Adjustable clamping force and large clamping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

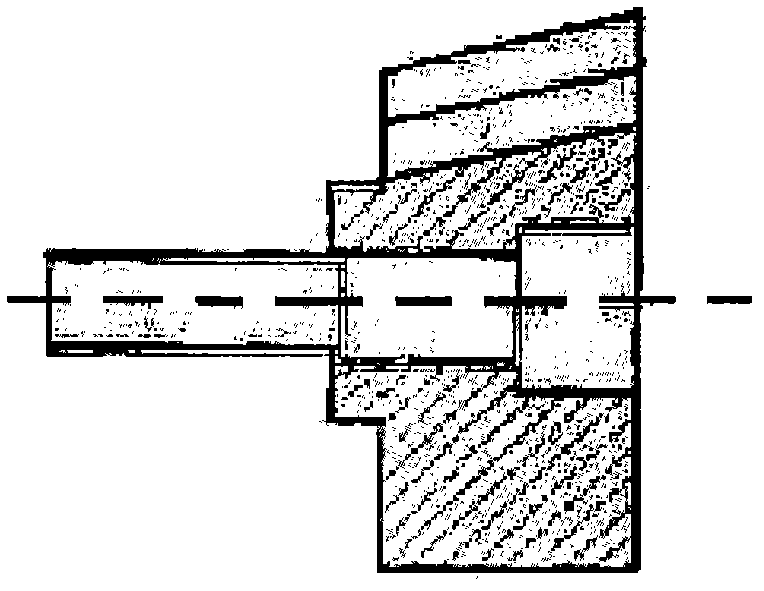

[0013] With reference to the accompanying drawings: the power chuck is mainly composed of a chuck body 1, a slide seat 2, a T-shaped key 3, a claw 4, a dust cover 5, a sliding shaft 6, a positioning key 7, an adjustment pad 8, and a pull rod 9. The separated chuck body manufactures the chuck packing and the guide block separately, and then assembles them into one body, changing the guide groove from an overall semi-closed structure to an open surface, improving the groove width accuracy and the smoothness of the guide surface, and improving the quality of the chuck. The movement accuracy and service life of the disc are improved; the inverted cone chuck is also interchangeable; the rounded corner transition is used to increase the diameter range of the clamped workpiece.

[0014] Chuck body 1 is connected together with cylinder or oil cylinder piston by connecting screw and pull rod 9. When the cylinder is ventilated and the piston is moved, the connecting screw also moves wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com