Back-twisting wire stranding machine

A stranding machine and stranding technology, which is applied to auxiliary devices for rope making, textiles and papermaking, electrical components, etc., can solve the problems that the reel 13 cannot be too large, increase the number of replacements of the reel 13, and affect work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

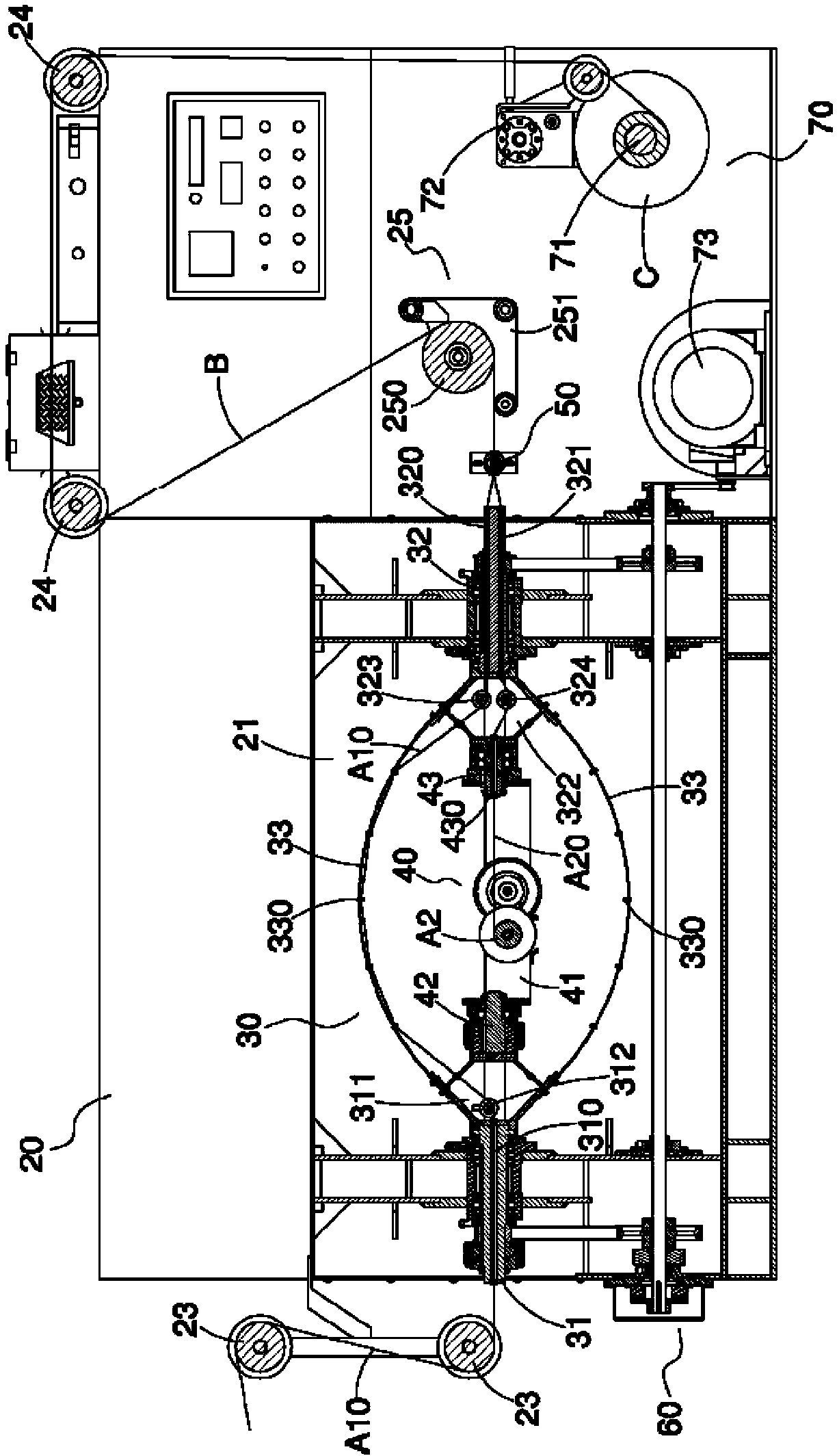

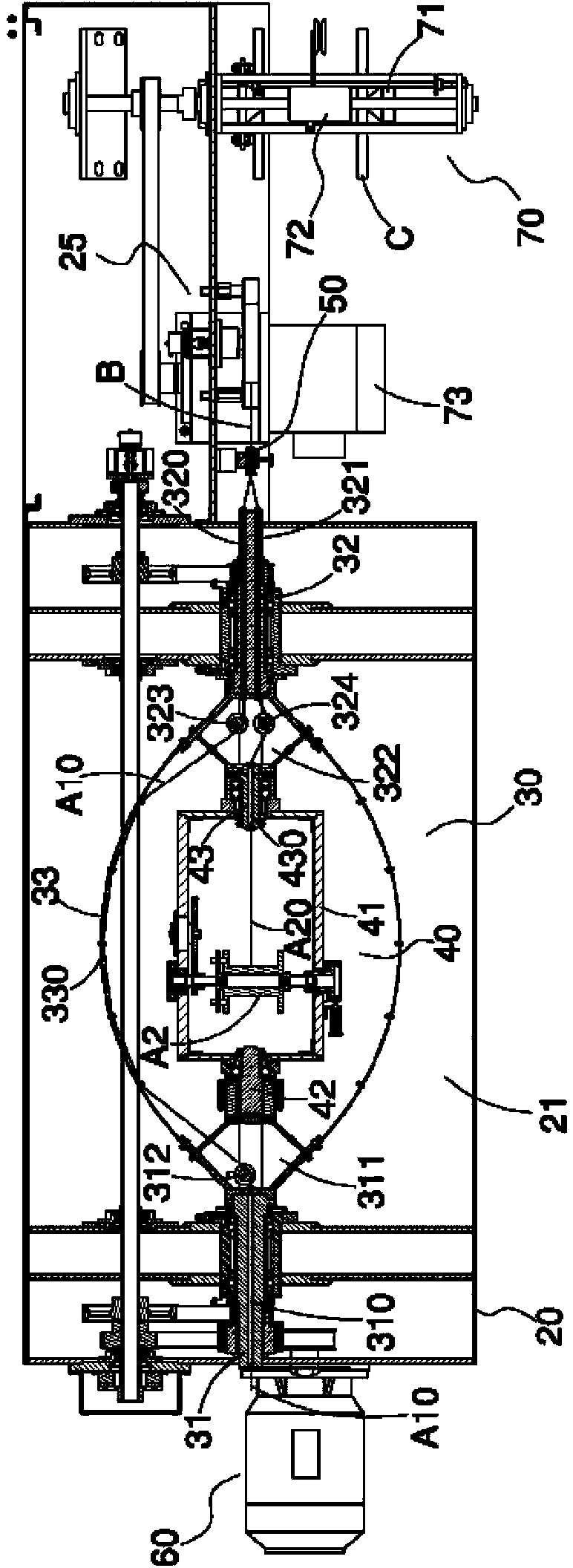

[0051] see Figure 2 to Figure 5 As shown, it is pointed out that the untwisted wire twisting machine of the present invention includes a machine platform 20, a wire twisting device 30, a line wheel frame 40, a twisted wire eye mold 50, a driving device 60, a winding device 70 and a Cover 80. in:

[0052] There is a working chamber 21 in the machine table 20 . The machine platform 20 has a working window 22 connected to the working chamber 21 . There are several freely rotatable leading wire pulleys 23, rear wire pulleys 24 and a pulley set 25 on the machine platform 20. The pulley set 25 can be composed of a pulley 250 and a pulley set 251, and the pulley set 25 can also be double pulleys (not shown in the figure) side by side.

[0053] The wire twisting device 30 includes a first shaft 31 , a second shaft 32 and two bow arms 33 . The first shaft 31 and the second shaft 32 are respectively rotatable and coaxially pass through two opposite side walls of the working chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com