Tyre movement mechanism in X-ray tyre testing equipment

A technology for testing equipment and motion mechanisms, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of high processing cost of worm gears, large resistance of worm gear transmission, and large heat generation of worm gear transmission. Achieve the effects of eliminating adverse effects, high detection repeatability, and simple installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be described below in conjunction with specific embodiments.

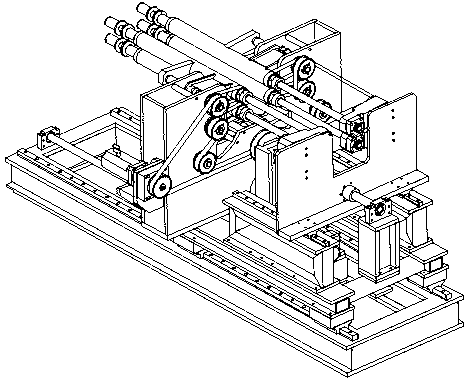

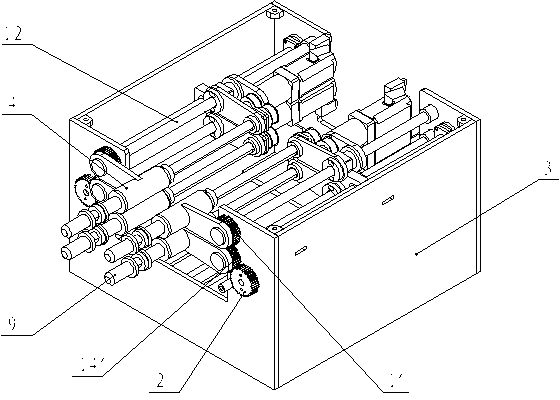

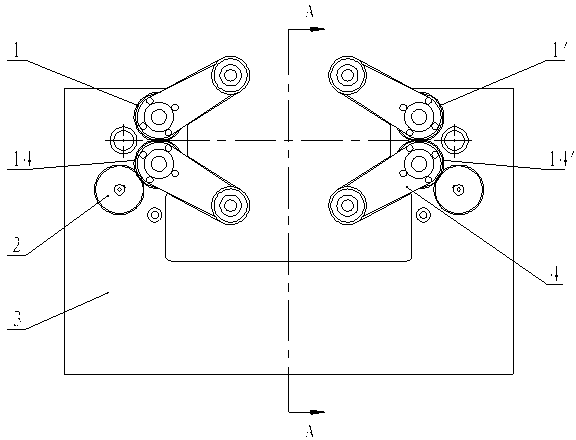

[0032] like figure 2 , image 3 and Figure 5 Shown, are respectively the tire kinematic mechanism assembly axonometric view and its front view and top view of the present invention, Figure 4 for image 3 A-A sectional view of the tire kinematic mechanism shown. The tire movement mechanism of the present invention includes a tire tire execution mechanism, a tire expansion mechanism and a tire rotation mechanism.

[0033] The main body of the tire support actuator is two sets of gears arranged symmetrically, and each set of gears works independently of each other without interfering with each other. Every group of gears comprises three gears, promptly each group of gears is provided with a driving gear 2 and the first driven gear 1, the second driven gear 14, and the driving gear 2 meshes with the second driven gear 14, and the second driven gear 14 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com