Dynamic grounding pressure test device

A technology of ground pressure and testing device, which is applied in the direction of measuring device, inflation gas pressure measurement, fluid pressure measurement, etc., can solve the problem that tires cannot have ground pressure distribution of tires at the same time, and achieve the effect of simulating the real environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

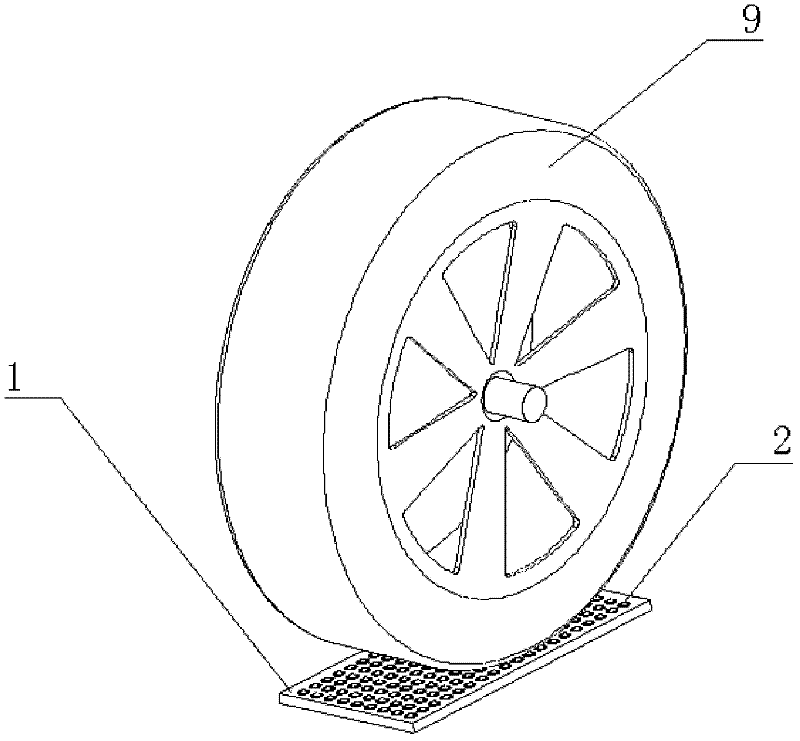

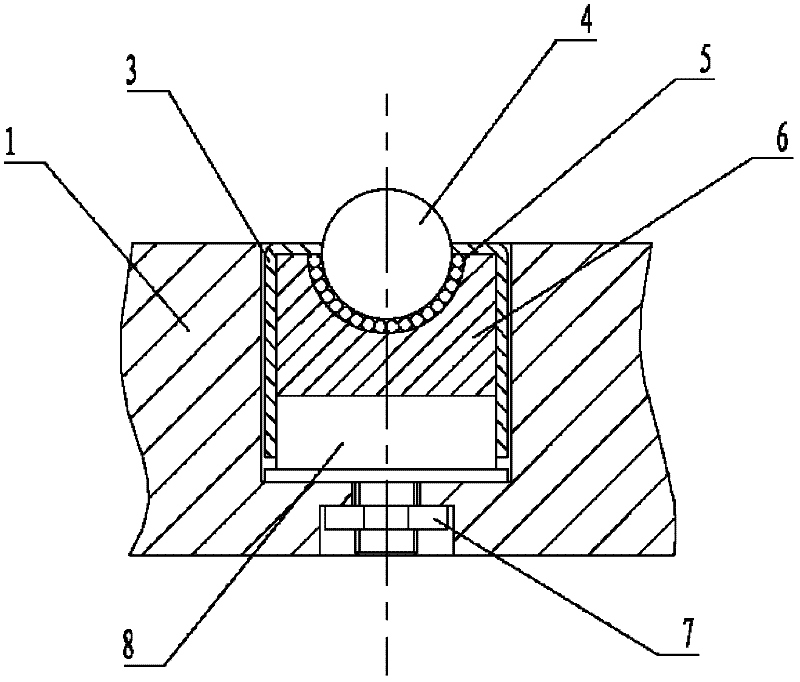

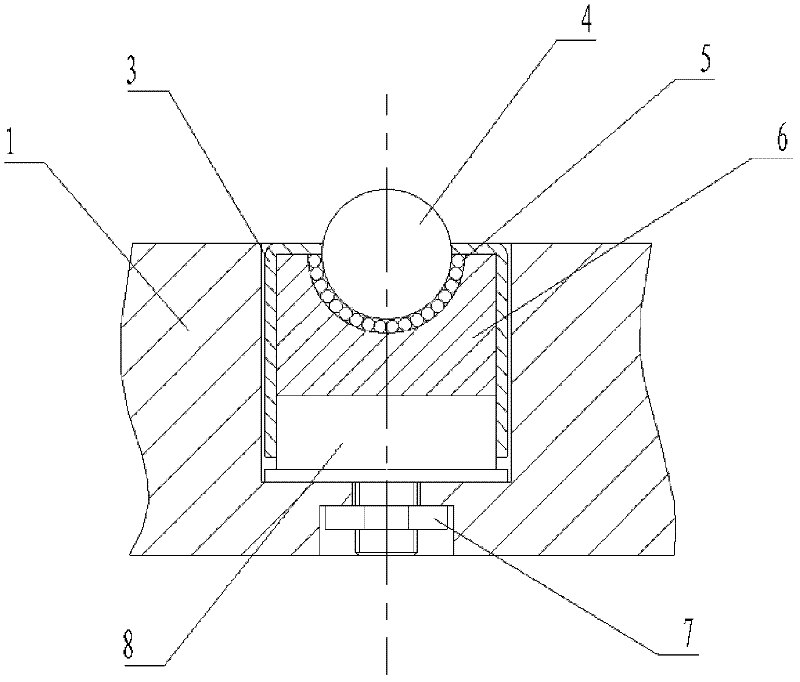

[0012] The dynamic ground pressure testing device of the present invention, such as figure 1 As shown, it is mainly composed of test platform 1, piezoelectric pressure sensor 8, data acquisition and processing system and universal ball seat 2. The data acquisition and processing system is not shown in the figure, and a certain number of steps are set on the surface of test platform 1. The stepped holes are arranged in an array, and a pressure sensor 8 is arranged in each stepped hole, see figure 2 As shown, the piezoelectric pressure sensor 8 is fixed on the test platform 1 by using the nut 7 and the screw head at the bottom of the piezoelectric pressure sensor 8, and a universal ball is installed on the upper part of each piezoelectric pressure sensor 8. Seat 2, universal ball seat 2 is composed of universal ball 4, ball 5, fixed sleeve 3 and base 6, the upper part of base 6 is a hemispherical raceway, and a certain number of balls with the same radius are arranged on the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com