Sintering method of high-grade high-titania vanadium-titanium magnetite concentrate

A technology of vanadium-titanium magnetite concentrate and sintering method, which is applied in the field of sintering of high-grade high-titanium vanadium-titanium magnetite concentrate, can solve problems such as experimental studies that have not been reported, and achieve improved quality, reduced output, improved mineral composition and structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

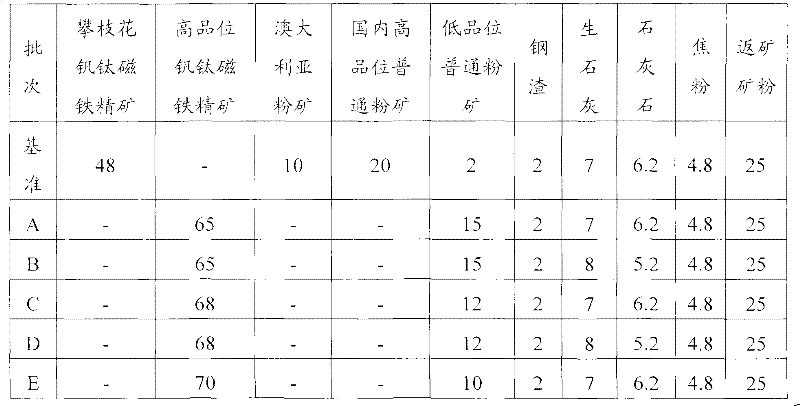

Embodiment 1

[0046] Option A

[0047] The proportion of high-grade vanadium-titanium magnetite concentrate is 65%, the proportion of low-grade ordinary fine ore is 15%, the proportion of returned ore powder is 25%, the proportion of quicklime is 7%, the proportion of limestone is 6.2%, and the proportion of coke powder is The ratio is 4.8%, the ratio of quicklime digestion water is 2:1, and the water content of the sintering mixture is 7.5±0.1wt%.

[0048] The results show that the proportion of sinter mixture with particle size greater than 3mm is more than 60wt%, the drum strength of sintered ore is 74%, the sintered finished product rate is 75wt%, the TFe grade of sintered ore is 50.1wt%, SiO 2 Content is 5.3wt%, TiO 2 The content is 6.5wt%, and the sintering basicity is 2.25±0.05.

Embodiment 2

[0050] Option B

[0051] The proportion of high-grade vanadium-titanium magnetite concentrate is 65%, the proportion of low-grade ordinary fine ore is 15%, the proportion of returned ore powder is 25%, the proportion of quicklime is 8%, the proportion of limestone is 5.2%, and the proportion of steel slag is The proportion of coke powder is 4.8%, the proportion of quicklime digestion water is 2:1, and the moisture content of sintering mixture is 7.6±0.1wt%.

[0052] The results show that the proportion of sinter mixture with particle size greater than 3mm is more than 65wt%, the drum strength of sintered ore is 75%, the sintered finished product rate is 76wt%, the TFe grade of sintered ore is 50wt%, SiO 2 Content is 5.2wt%, TiO 2 The content is 6.5wt%, and the sintering basicity is 2.3±0.05.

Embodiment 3

[0054] Plan C

[0055] The proportion of high-grade vanadium-titanium magnetite concentrate is 68%, the proportion of low-grade ordinary powder ore is 12%, the proportion of returned ore powder is 25%, the proportion of quicklime is 7%, the proportion of limestone is 6.2%, and the proportion of steel slag is The proportion of coke powder is 4.8%, the proportion of quicklime digestion water is 2:1, and the moisture content of sintering mixture is 7.6±0.1wt%.

[0056] The results show that the proportion of sinter mixture with particle size greater than 3mm is more than 60wt%, the drum strength of sintered ore is 74%, the sintered finished product rate is 74.5wt%, the TFe grade of sintered ore is 50.4wt%, SiO 2 Content is 4.8wt%, TiO 2 The content is 6.8wt%, and the sintering basicity is 2.45±0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com