Double-sided adhesive tape and display device having touch panel

A double-sided adhesive tape technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of narrow frame width, difficult to use large display screen mobile phones, difficult adhesion and other problems , to achieve the effect of excellent adhesion and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

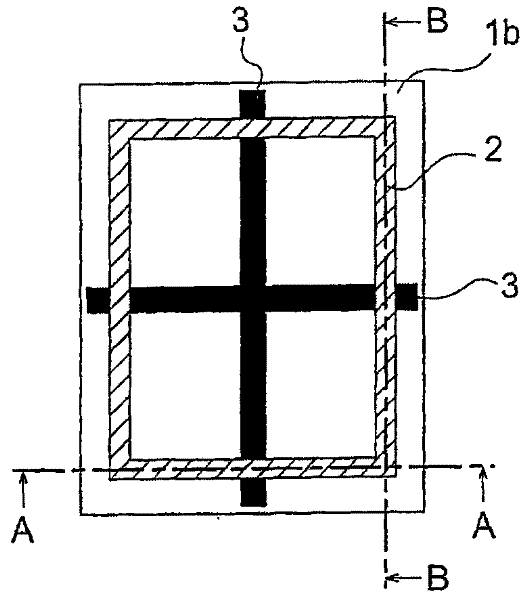

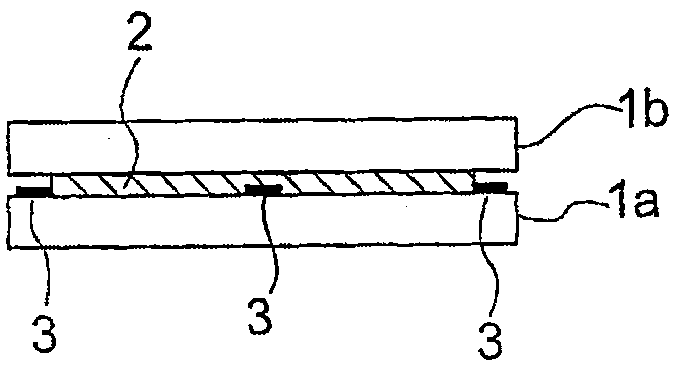

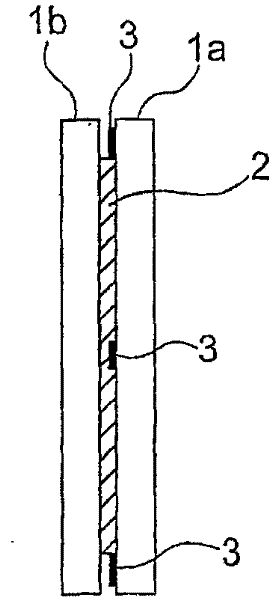

Image

Examples

Embodiment 1

[0119] A film of ethylene-methacrylic acid copolymer (manufactured by Mitsui Dupont Polymicul Co., Ltd., product name 'N0903HC', 91% by mass of olefinic monomer unit) was produced at a thickness of 100 μm, and corona treatment was performed on both sides to obtain a core material membrane. Next, on the release-treated surface of the light release sheet (manufactured by Lintec Co., Ltd., trade name 'SP-PET381031'), apply the adhesive agent forming coating with a doctor blade so that the thickness after drying is 50 μm. Liquid 1 was heat-dried at 100°C for about 2 minutes to perform thermal crosslinking. Then, the above-mentioned core material film was laminated on the adhesive layer to obtain a single-sided adhesive tape.

[0120] Then, on the release-treated surface of the heavy-release sheet (manufactured by Lintec Co., Ltd., trade name 'SP-PET3811'), a coating for forming an adhesive was applied using a doctor blade applicator so that the thickness after drying was 50 μm. ...

Embodiment 2

[0122] About Example 1, except having used the coating liquid 2 for adhesive agent formation instead of the coating liquid 1 for adhesive agent formation, it carried out similarly to Example 1, and produced the double-sided adhesive tape.

Embodiment 3

[0124] For Example 1, except that the core material film is a film that is corona-treated on both sides of a polyethylene film (manufactured by Tamapoli Corporation, product name 'A-1', thickness 100 μm), the same procedure as in Example 1 was followed. Way to make double-sided adhesive tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com