Unevenness follow-up property laminated member and display device attached with touch panel using same

A follow-up, lamination technology, applied in applications, layered products, household appliances, etc., can solve the problems of adhesive exudation pass rate, inability to obtain sufficient optical adaptability, height difference followability, image quality degradation, etc. , to achieve the effect of excellent elongation and excellent fit adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

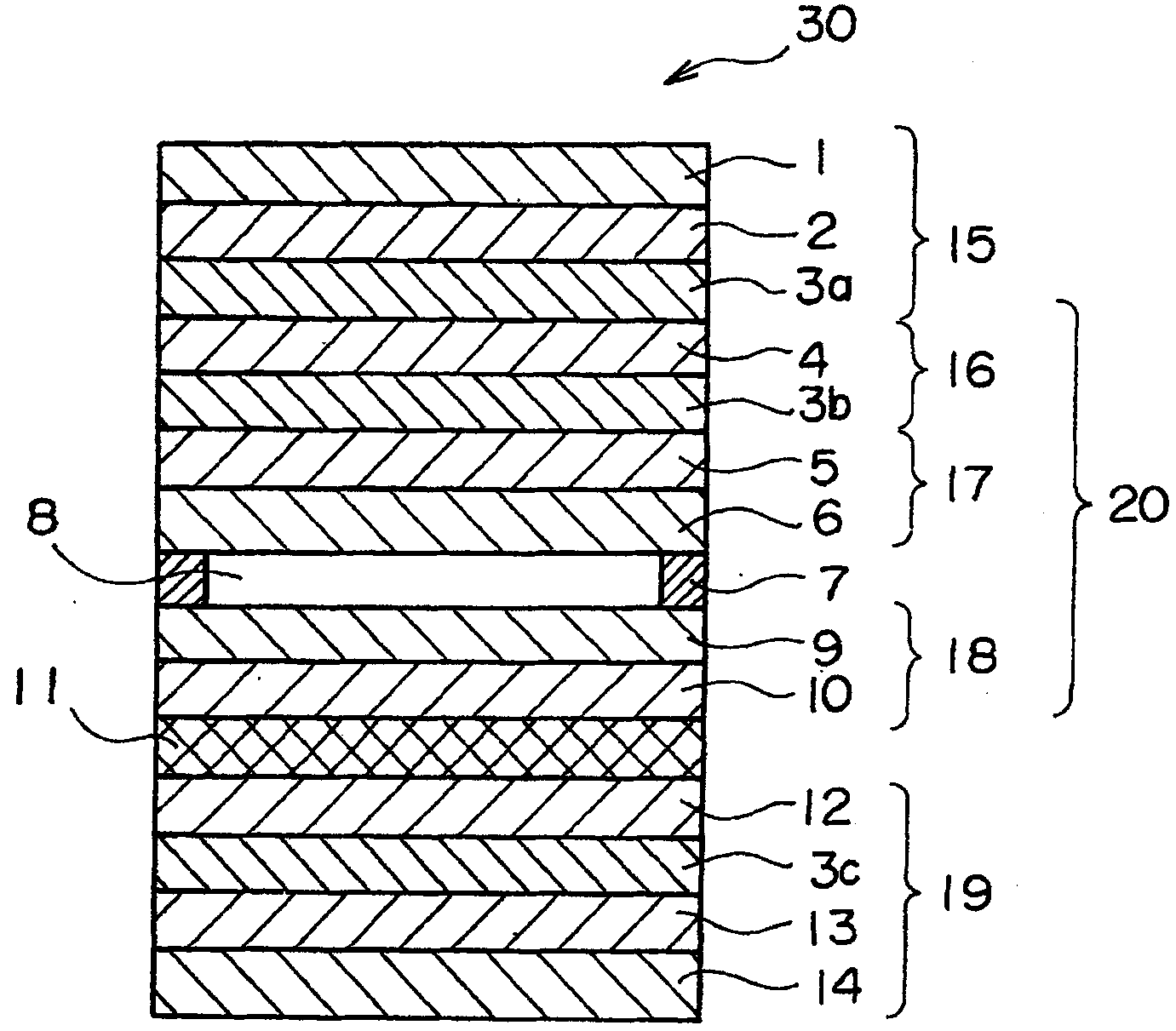

[0095] On a release film (manufactured by Lintec, trade name 'SP-PET38T103-1', thickness 38 μm), use a slit coater to coat the coating for forming the resin layer (A) so that the film thickness after drying becomes 20 μm. The lotion 1 was dried at 120°C for 1 minute, and then bonded with a release film (manufactured by Lintec, trade name 'SP-PET381031', thickness 38 µm) to obtain a stress buffering resin layer (A) 6 . Next, a resin layer (B) was formed by applying a resin layer (B) on a release film (manufactured by Lintec, trade name 'SP-PET38T103-1', thickness 38 μm) using a slit coater so that the film thickness after drying was 40 μm. The coating liquid 4 was dried at 120° C. for 1 minute, and then the coated surface was attached to the stress buffering resin layer (A) 6 from which one peeling film was peeled off, to obtain a laminate. In addition, on a release film (manufactured by Lintec, trade name 'SP-PET381031', thickness 38 μm), a coating for forming the resin layer ...

Embodiment 2

[0097] About Example 1, the same operation as Example 1 was performed except having used the coating liquid 2 for resin layer (A) formation instead of the coating liquid 1 for resin layer (A) formation. The irregularity following laminated part 8 was obtained. Table 1 shows the evaluation results of each characteristic.

Embodiment 3

[0099] Regarding Example 1, the same operation as in Example 1 was performed except that the coating solution 5 for forming the resin layer (B) was used instead of the coating solution 4 for forming the resin layer (B) for both layers of the resin layer (B). The irregularity following laminated part 9 was obtained. Table 1 shows the evaluation results of each characteristic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com