Method for processing sodium oxalate crystallized from industrial sodium aluminate solution

An industrial sodium aluminate, crystallized technology, applied in the field of sodium oxalate, can solve the problems of increasing production costs, polluting the environment, etc., and achieve the effects of low price, environmental friendliness, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

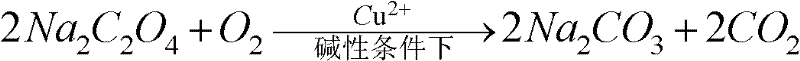

Method used

Image

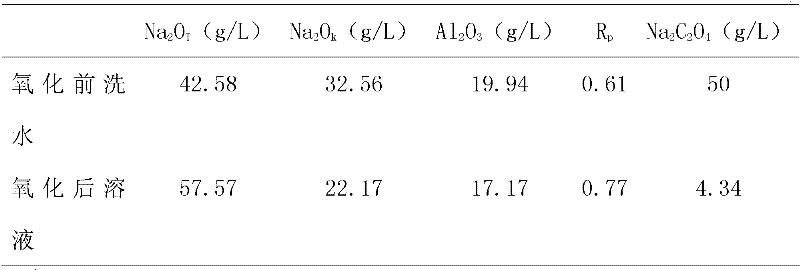

Examples

Embodiment 1

[0031] 500mL of self-prepared sodium hydroxide solution, 25g of sodium oxalate (oxalate content is 32.84g / L), and 1.0g (2g / L) of copper oxide are added to the autoclave. The volume of oxygen is 0.05Nm 3 ~1Nm 3 / kg sodium oxalate; feed air at 2MPa, stir, and react at 260°C for 4.5h. The content of oxalate in the solution after catalytic oxidation was 1.61g / L, and the oxidation rate of sodium oxalate was 95.11%.

Embodiment 2

[0033] 500mL of self-prepared sodium hydroxide solution, 20g of sodium oxalate (oxalate content is 26.27g / L), and 0.4g (0.8g / L) of copper oxide are added to the autoclave, and the oxygen volume is 0.05Nm 3 ~1Nm 3 / kg sodium oxalate; feed air at 2MPa, stir, and react at 260°C for 4h. The content of oxalate in the solution after catalytic oxidation was 2.11g / L, and the oxidation rate of sodium oxalate was 91.95%.

Embodiment 3

[0035] 500mL of self-prepared sodium hydroxide solution, 50g of sodium oxalate (oxalate content is 65.67g / L), and 0.8g (1.6g / L) of copper oxide are added to the autoclave, and the oxygen volume is 0.05Nm 3 ~1Nm3 / kg sodium oxalate; feed air at 2MPa, stir, and react at 260°C for 6h. The oxalate content in the solution after catalytic oxidation was 0.37g / L, and the oxidation rate of sodium oxalate was 99.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com