Container capable of automatically controlling discharge amount of materials therein

A technology of discharge and content, applied in the direction of unloading device, powder material distribution, etc., can solve the problems of unsanitation, standardization, and inability to achieve weight, and achieve the effect of avoiding unsanitary, small occupied area, and avoiding errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

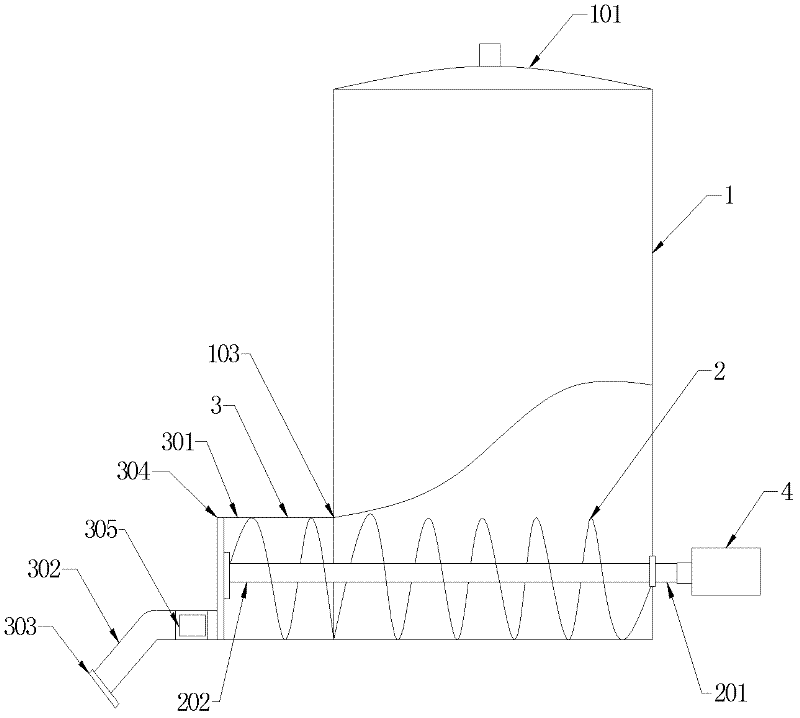

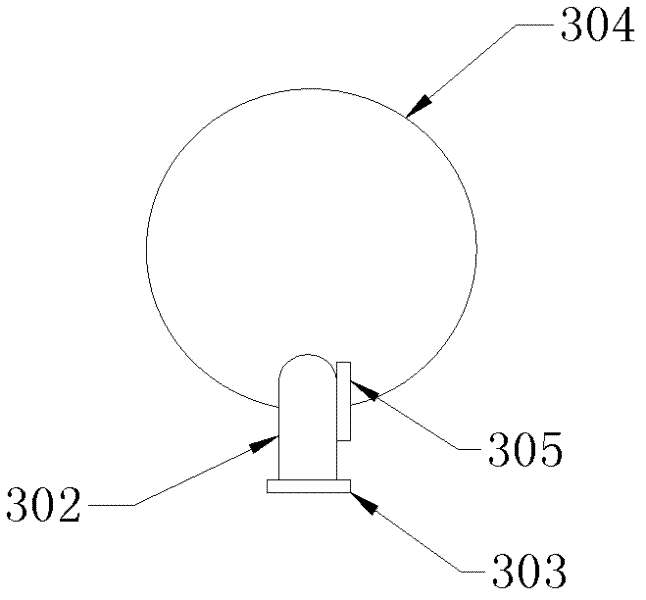

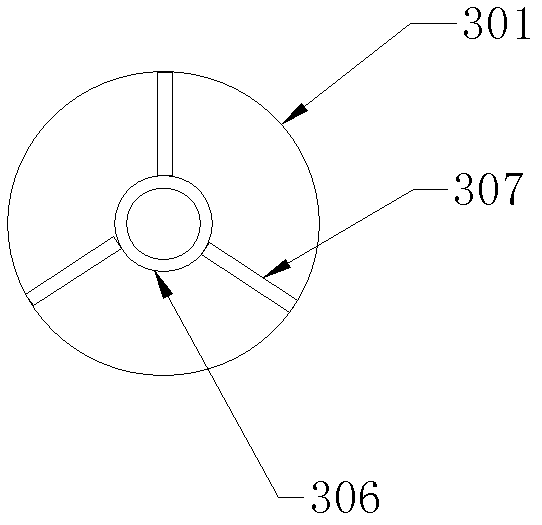

[0019] Such as figure 1 As shown, this solution includes a rice bucket 1 for containing rice, a screw rod 2 is installed at the bottom of the rice bucket 1, the tail end 201 of the screw rod is connected with the drive motor 4, and a through hole 103 is opened on the wall of the rice bucket corresponding to the front end 202 of the screw rod , a rice outlet pipe 3 is fixed on the outside of the through hole 103, the screw rod front end 202 is fixed in the rice outlet pipe 3 by the bearing 306, and a bucket cover 101 is arranged on the top of the rice bucket 1. The bucket lid of this program ensures that the rice bucket does not need to be used. Open, to avoid the pollution of the external environment. A movable door 303 is arranged at the opening end of the meal outlet pipe 3, and the movable door 303 is installed movably in a manner tangential to the axis of the meal outlet pipe 3. Such as Figure 5 As shown, the opening and closing of the dodge door 303 is controlled by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com