Aircraft hydraulic anti-skid braking pressure supply device

A technology of anti-skid brakes and aircraft hydraulics, applied in the field of aircraft hydraulics, can solve problems such as inability to adjust brake pressure, tire blowouts, and long idling time of hydraulic pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

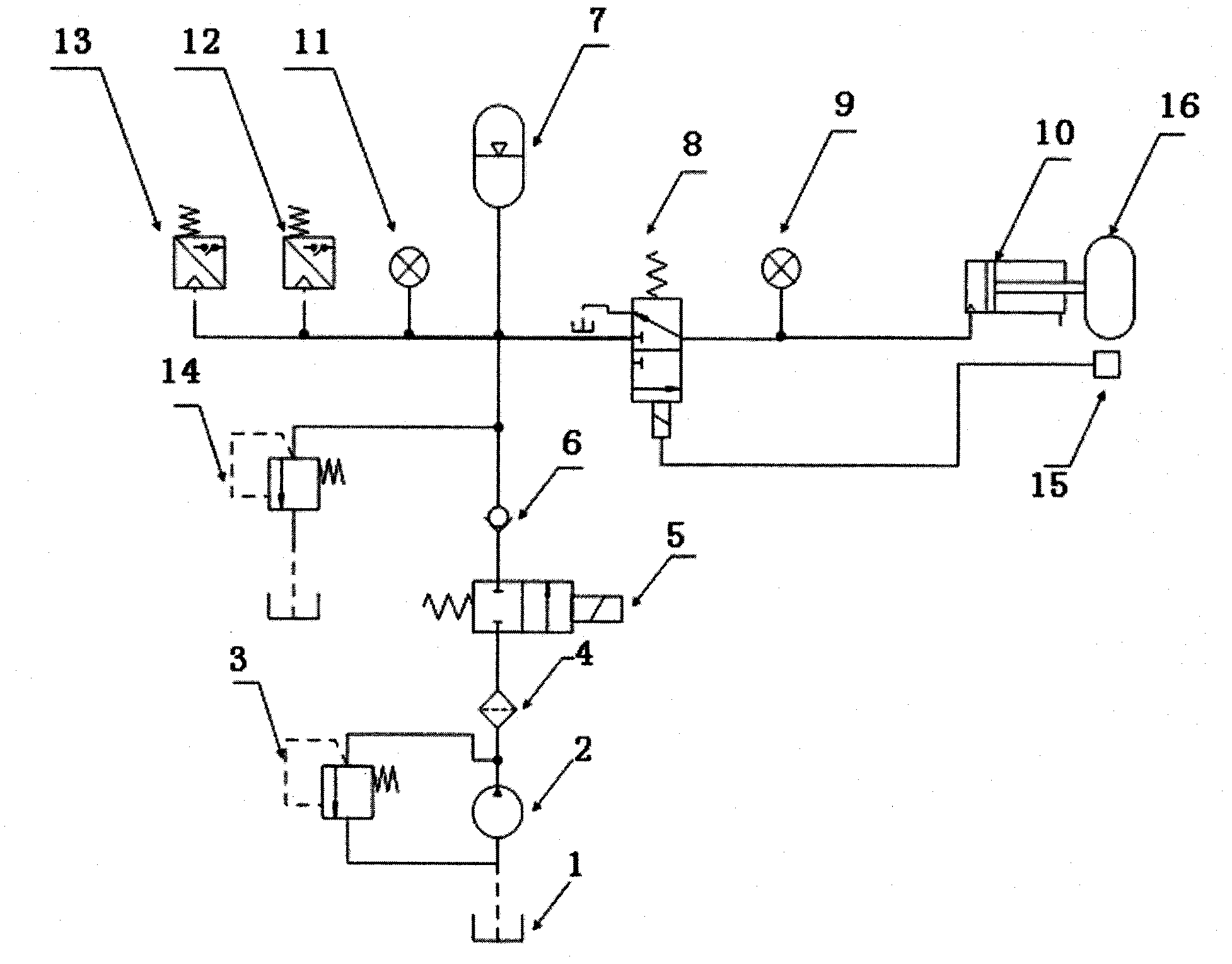

[0012] An aircraft hydraulic anti-skid brake pressure supply device is characterized in that it includes a brake pressure accumulator 7, a pressure switch 12, an electric pump 2, a charging solenoid valve 5, an anti-skid brake valve 8, a brake pressure sensor 9, and a pressure supply pressure sensor 11 , pressure relay 13, pressure supply relief valve 14, pressure relief valve 3, check valve 6 and oil filter 4, speed sensor and control box 15;

[0013] One end of the electric pump 2 is connected to the oil tank 1, and the other end is connected to one end of the oil filter 4 and the pressure relief valve 3, and the other end of the oil filter 4 is connected to the inlet of the charging solenoid valve 5, and the charging solenoid valve 5 The two outlets are respectively connected to the oil filter 4 and one end of the check valve 6, the other end of the check valve 6 is connected to the brake accumulator 7, the brake accumulator 7 is connected to the pressure relay 13, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com