Preparation method of photoinduction nano alternative-current power generator based on zinc oxide/ polyaniline/zinc oxide

An alternator, zinc oxide technology, applied in the direction of light radiation generator, generator/motor, etc., to achieve the effect of simple preparation process, single shape and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Treatment of conductive glass:

[0027] The ITO conductive glass used as the working electrode was pre-cut into strips of 2cm×1cm, firstly ultrasonicated in absolute ethanol for 15 minutes, and then ultrasonicated in ethanol aqueous solution of sodium hydroxide (the volume ratio of ethanol to water was 1:1) After 15 minutes, ultrasonically clean with absolute ethanol and deionized water respectively, and finally blow dry with nitrogen for use.

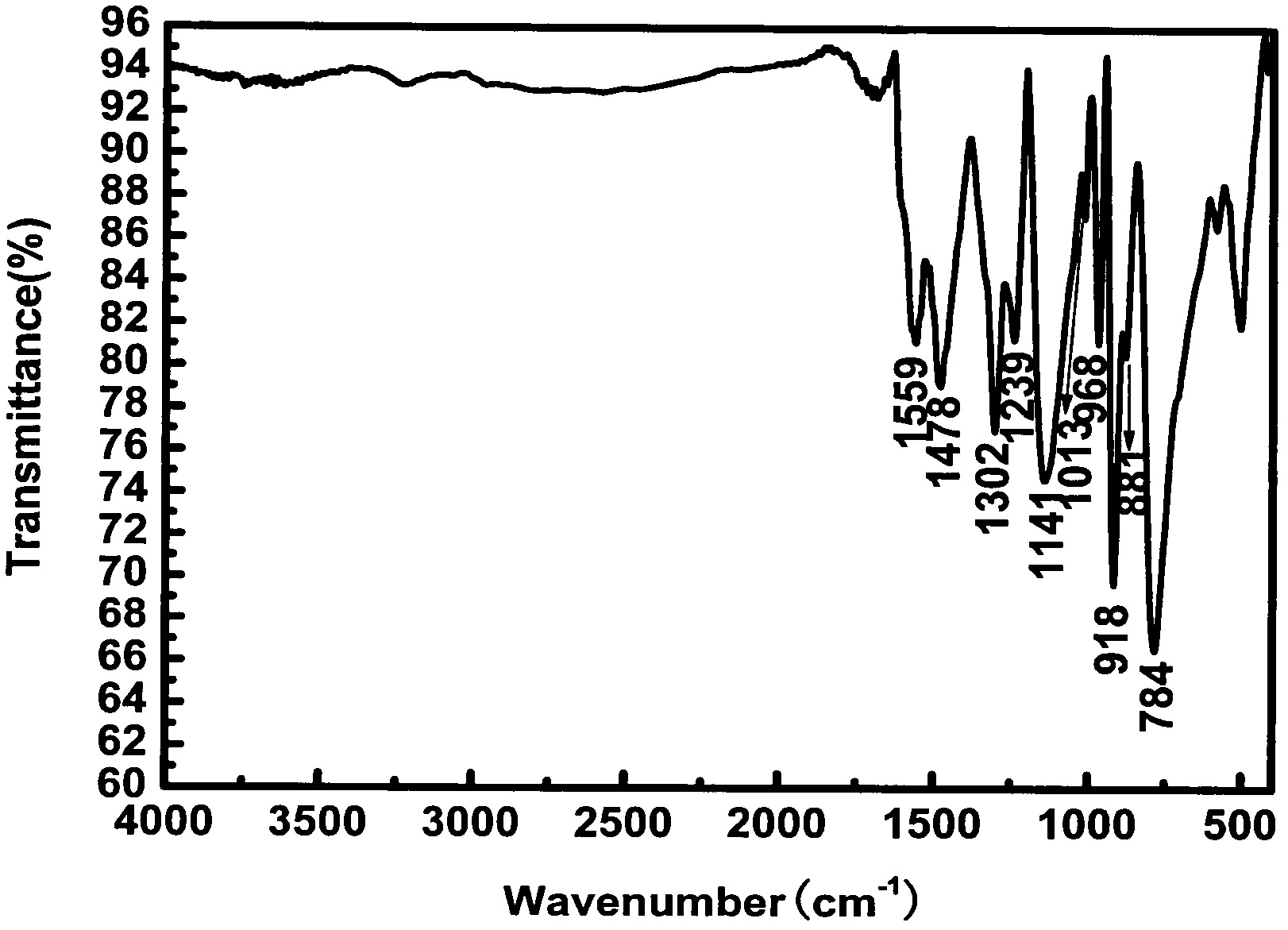

[0028] 2. Synthesis of polyaniline nanofibers: carried out in a 50 ml glass container. 3.28 g K 2 S 2 o 8 and 5 g H 4 SiW 12 o 40 The acid was dissolved in 20 mL of deionized water and stirred evenly in an ice bath to form mixture 1. Subsequently, 10 drops of aniline were pipetted with a dropper and dissolved in 20 ml of chloroform, and stirred evenly in an ice bath to form a mixture 2. Mixture 1 was carefully added to Mixture 2 to form a liquid-liquid interface. The interfacial reaction was carried out at 0°C-5°C fo...

Embodiment 2

[0032] 1. Treatment of conductive glass:

[0033] The ITO conductive glass used as the working electrode was pre-cut into strips of 2cm×1cm, firstly ultrasonicated in absolute ethanol for 15 minutes, and then ultrasonicated in ethanol aqueous solution of sodium hydroxide (the volume ratio of ethanol to water was 1:1) After 15 minutes, ultrasonically clean with absolute ethanol and deionized water respectively, and finally blow dry with nitrogen for use.

[0034] 2. Synthesis of polyaniline nanofibers:

[0035] Do this in a 50ml glass container. 3.28 g K 2 S 2 o 8 and 5 g H 4 SiW 12 o 40 The acid was dissolved in 20 mL of deionized water and stirred evenly in an ice bath to form mixture 1. Subsequently, 10 drops of aniline were pipetted with a dropper and dissolved in 20 ml of chloroform, and stirred evenly in an ice bath to form a mixture 2. Mixture 1 was carefully added to Mixture 2 to form a liquid-liquid interface. The interfacial reaction was carried out at 0-5°C...

Embodiment 3

[0039] 1. Treatment of conductive glass:

[0040] The ITO conductive glass used as the working electrode was pre-cut into strips of 2cm×1cm, firstly ultrasonicated in absolute ethanol for 15 minutes, and then ultrasonicated in ethanol aqueous solution of sodium hydroxide (the volume ratio of ethanol to water was 1:1) After 15 minutes, ultrasonically clean with absolute ethanol and deionized water respectively, and finally blow dry with nitrogen for use.

[0041] 2. Synthesis of polyaniline nanofibers:

[0042] Do this in a 50ml glass container. 3.28 g K 2 S 2 o 8 and 5 g H 4 SiW 12 o 40 The acid was dissolved in 20 mL of deionized water and stirred evenly in an ice bath to form mixture 1. Subsequently, 10 drops of aniline were pipetted with a dropper and dissolved in 20 ml of chloroform, and stirred evenly in an ice bath to form a mixture 2. Mixture 1 was carefully added to Mixture 2 to form a liquid-liquid interface. The interfacial reaction was carried out at -2°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com