Wedge-shaped pre-tightened sandwich type rectangular four-pin linear ultrasonic motor vibrator

A linear ultrasonic motor, sandwich-type technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of complex structure, high processing and assembly precision requirements, etc. , to achieve the effects of improving mechanical output capability, simplifying the structure of the vibrator, and flexibly designing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

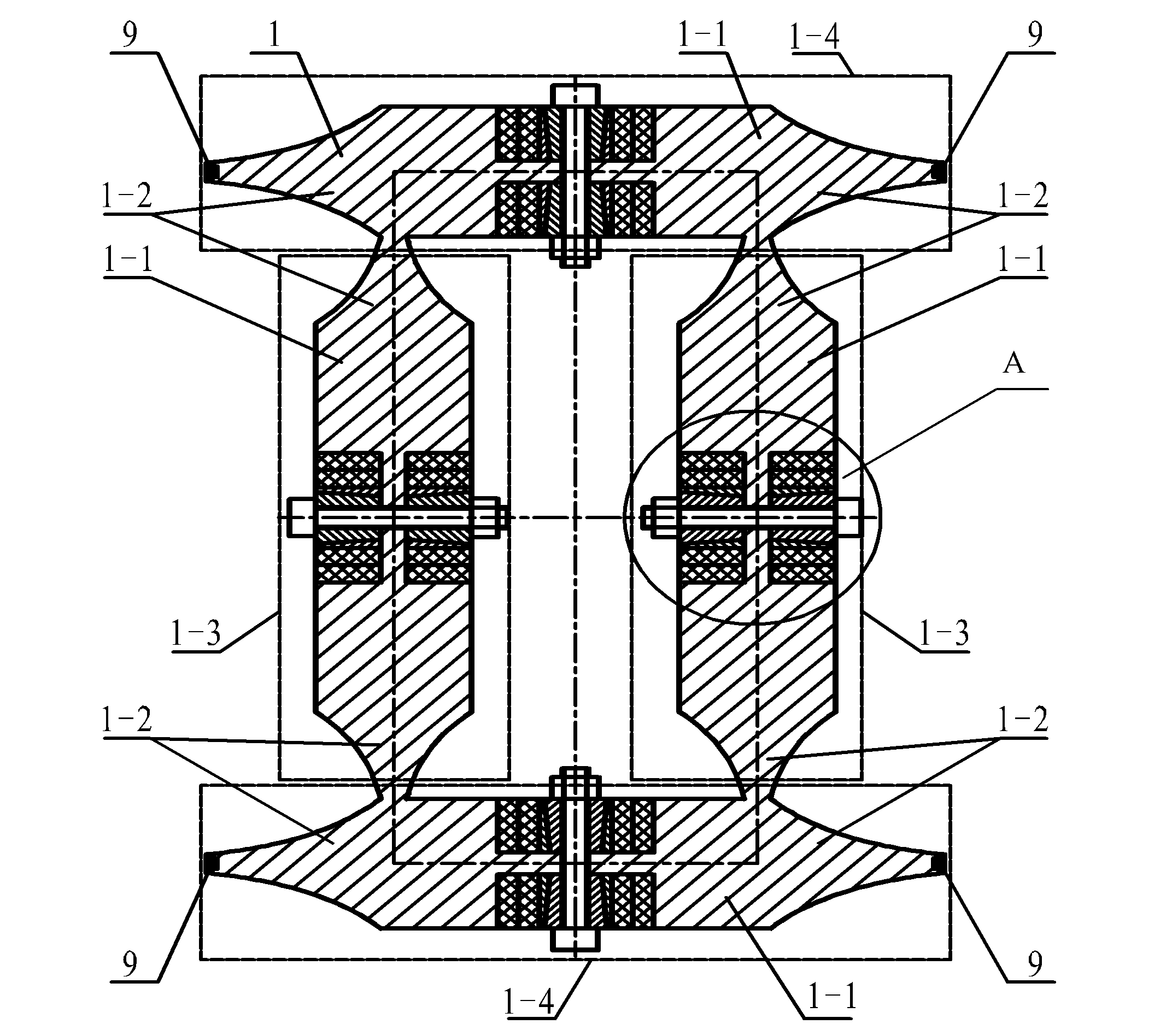

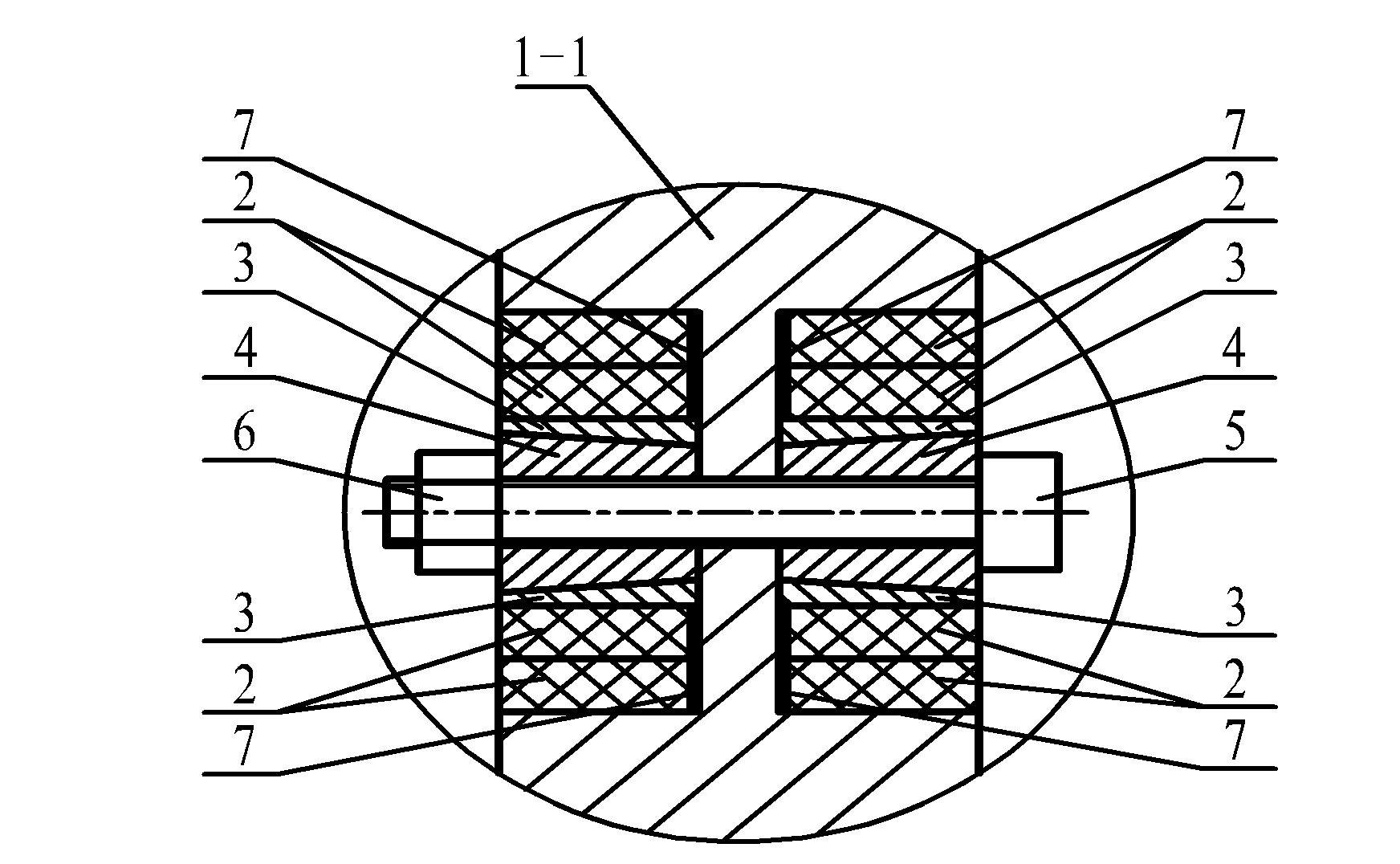

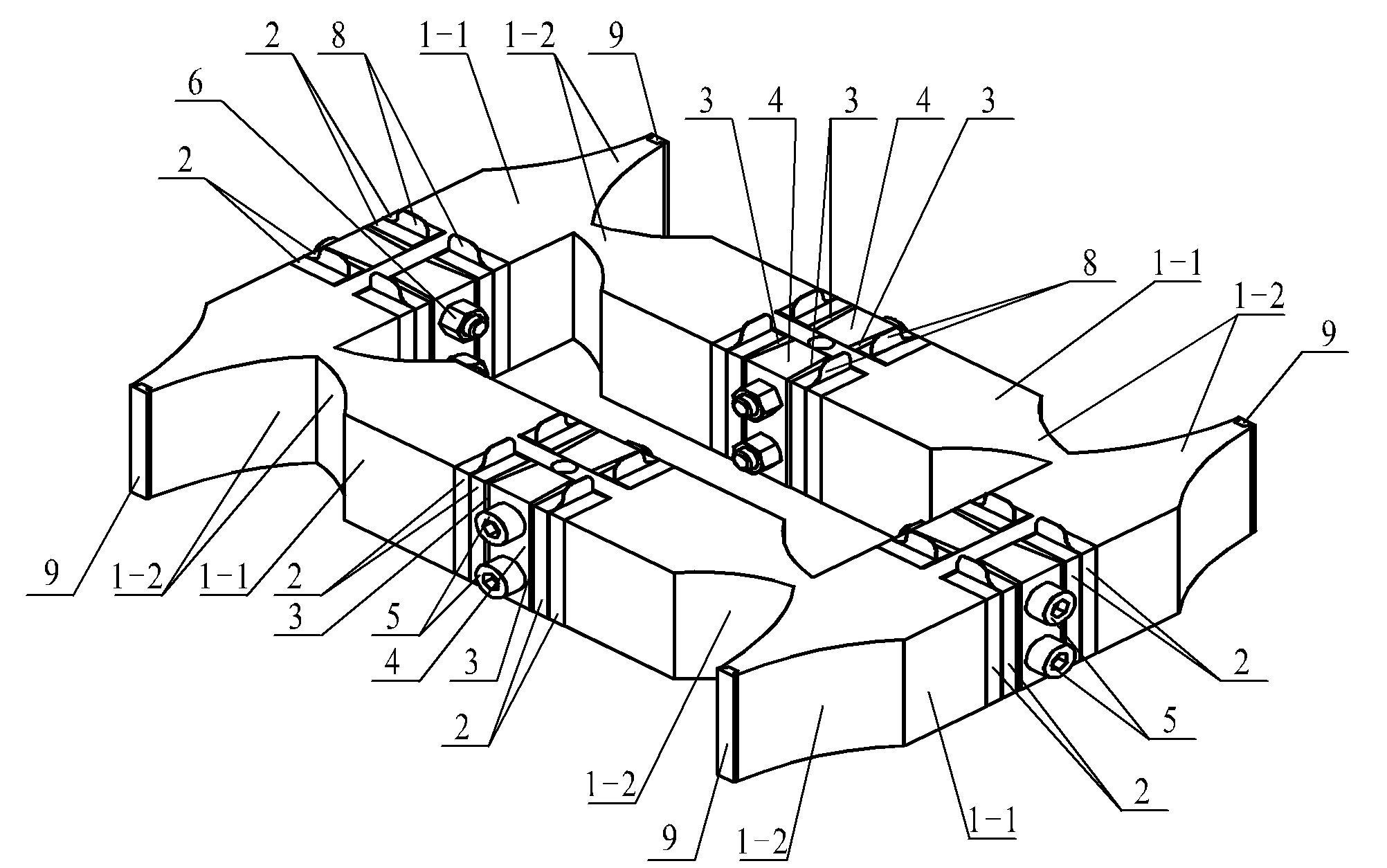

[0026] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, the sandwich-type quadruped linear ultrasonic motor vibrator adopting wedge-shaped pretension described in this embodiment, which includes a rectangular metal base 1, sixteen pairs of longitudinal vibration piezoelectric ceramic sheets 2, sixteen wedge-shaped blocks 3, Eight preloading blocks 4, preloading screws 5, preloading nuts 6, sixteen insulating gaskets 7 and sixteen electrode sheets 8,

[0027] The rectangular metal matrix 1 is composed of four composite beams of the same shape, divided into two horizontal composite beams 1-4 and two vertical composite beams 1-3,

[0028] Each composite beam is composed of a column beam 1-1 and two horns 1-2, the beam 1-1 is a quadrangular prism with a rectangular cross section, and the horn 1-2 is a rectangular cross section And gradually thinner quadrangular prism, two horns 1-2 are respectively arranged at the two end...

specific Embodiment approach 2

[0036] Specific implementation mode two: the following combination figure 1 , image 3 with Figure 4 Describe this embodiment, this embodiment is a further description of Embodiment 1, this embodiment also includes four friction plates 9,

[0037] The small end surface of the horn 1-2 of each horizontal composite beam 1-4 is provided with a long strip-shaped slot along its thickness direction, and the friction plate 9 is fixed on the horn 1-2 through the strip-shaped slot. 2 on the small end face.

specific Embodiment approach 3

[0038] Specific implementation mode three: the following combination image 3 with Figure 4 This embodiment is described. This embodiment is a further description of Embodiment 2. The friction plate 9 in this embodiment is covered on the small end surface of the horn 1-2 of the horizontal composite beam 1-4, and the friction plate The shape of the outer end face of 9 is identical with the shape of the place small end face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com