Current sensor mounting structure

A technology of current sensor and installation structure, which is applied in the direction of switchgear, electrical components, busbar/line layout, etc., which can solve the problems of inconvenient operation, hidden danger of current sensor replacement and maintenance accidents, low replacement and maintenance efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

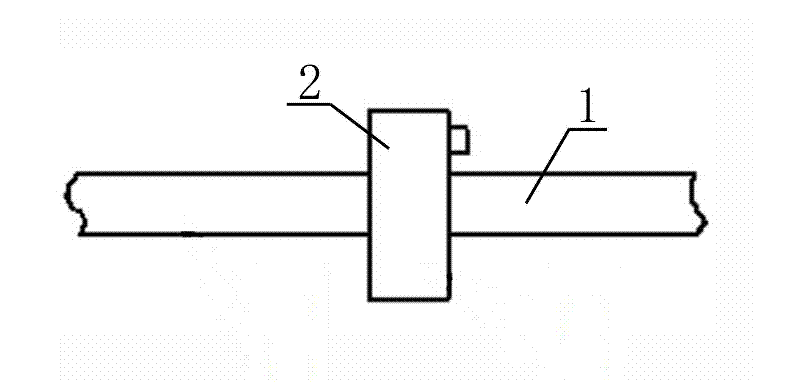

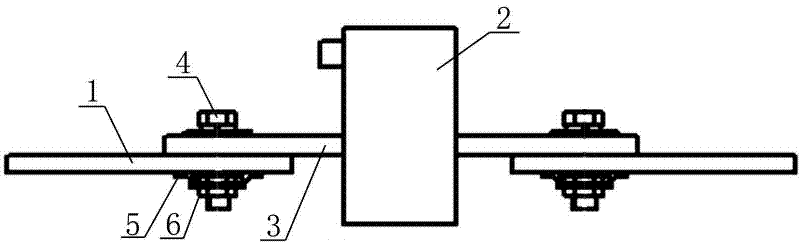

[0010] A current sensor installation structure, including a main side copper bar 1 and a current sensor 2; also includes a special installation copper bar 3; the current sensor 2 is installed through the special installation copper bar 3; both ends of the special installation copper bar 3 are installed through the Fixing bolts 4; the number of copper bars 1 on the main side is two; one end of the two main side copper bars 1 is fixed with a pressure plate 5, and the surface of the pressure plate 5 is installed with a cage nut 6; The bolts 4 respectively pass through the cage nuts 6 installed on the two main side copper bars 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com