H-type steel horizontal assembly welding grounding mechanism

A technology of H-beam and connecting seat, applied in the direction of connecting contact materials, etc., can solve problems such as poor fixation and waste, and achieve the effect of ensuring stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the embodiments in the drawings:

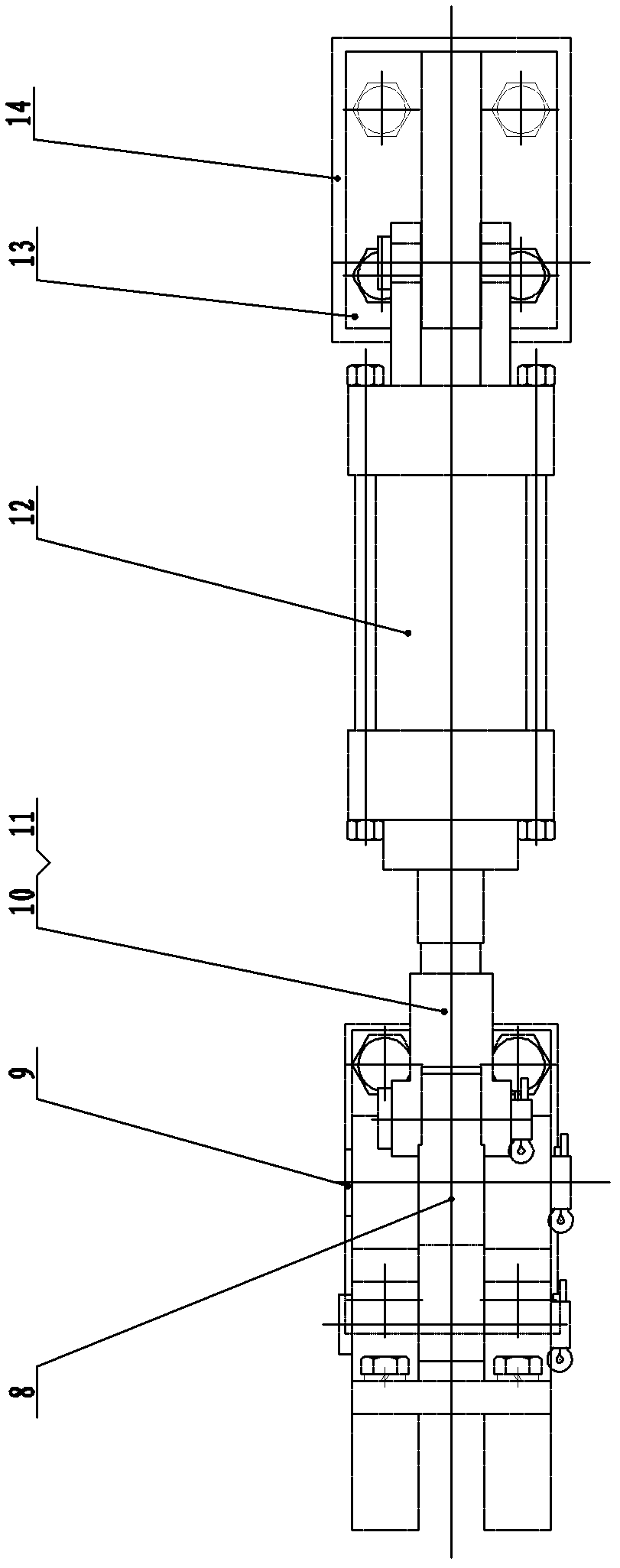

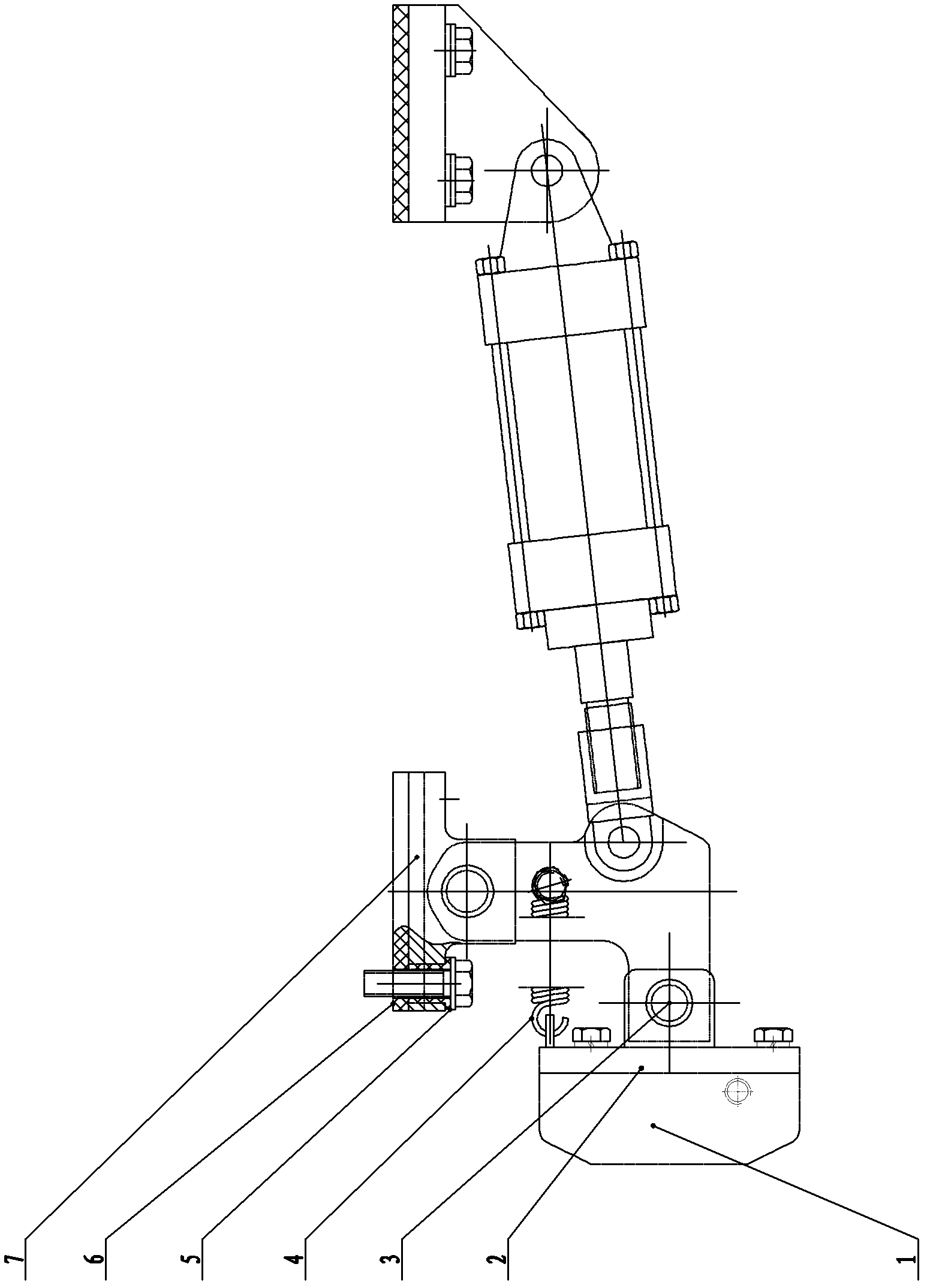

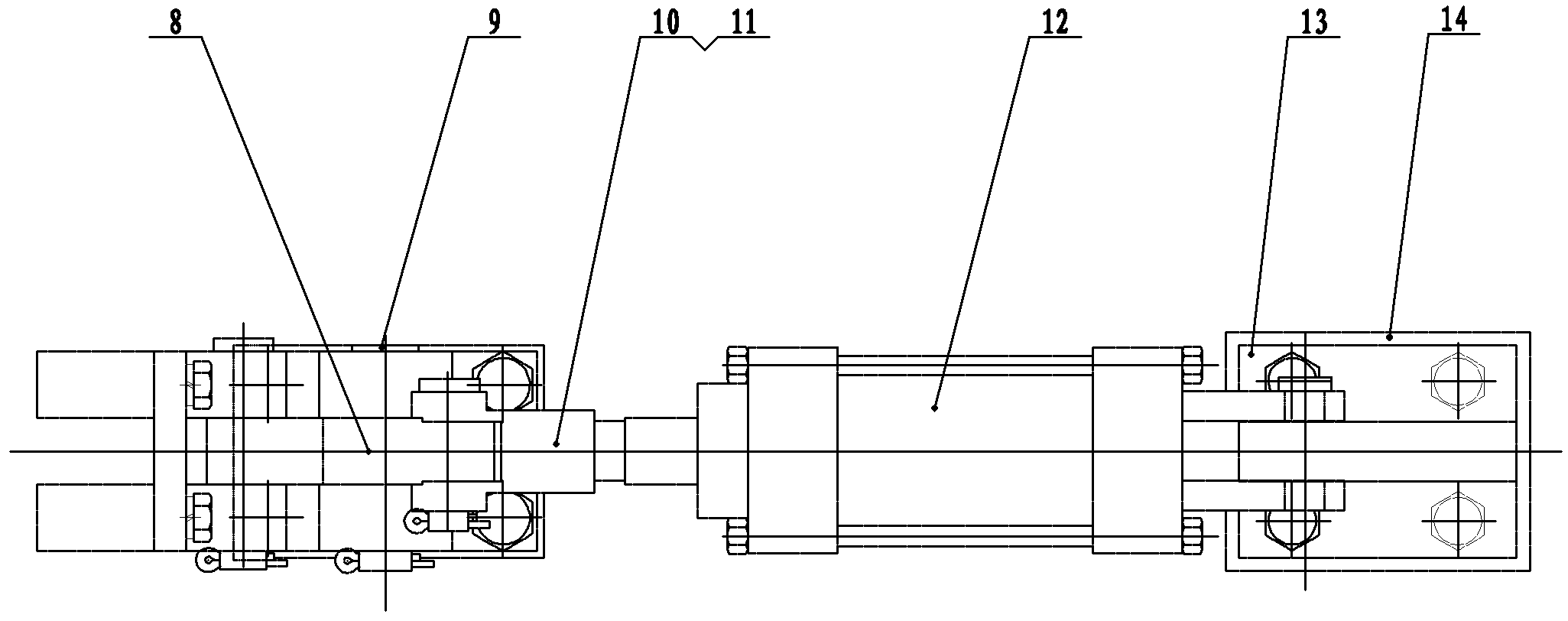

[0010] Such as Figure 1 ~ Figure 2 As shown, it includes a conductive block 1, a connecting seat 2, a first pin 3, a tension spring 4, a bakelite sleeve 5, an insulating plate 6, a fixing seat 7, a swing rod 8, a second pin 9 and a cylinder Y joint 10, The third pin 11, the double lug cylinder 12, the fixed seat 13, and the insulating plate 14.

[0011] In the present invention, a bakelite sleeve 5 is installed on the fixing seat 7, and the insulating plate 6 is fastened by bolts. The fixing base 7, the fixing base 13 and the insulating plate 14 are installed on the host. The function of the bakelite sleeve 5, the insulating plate 6 and the insulating plate 14 is to ensure that the negative electrode of the welding machine connected to the conductive device is insulated from the host; the fixing seat 13 is connected to the double lug cylinder 12 through the third p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com