Method and device for measuring spatial position between submarine pipeline flanges

A subsea pipeline and spatial location technology, which is applied to measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of economic loss of flanges, high daily rates, delay in construction period, etc., so as to shorten the offshore construction time and simplify the operation. , the effect of high installation success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

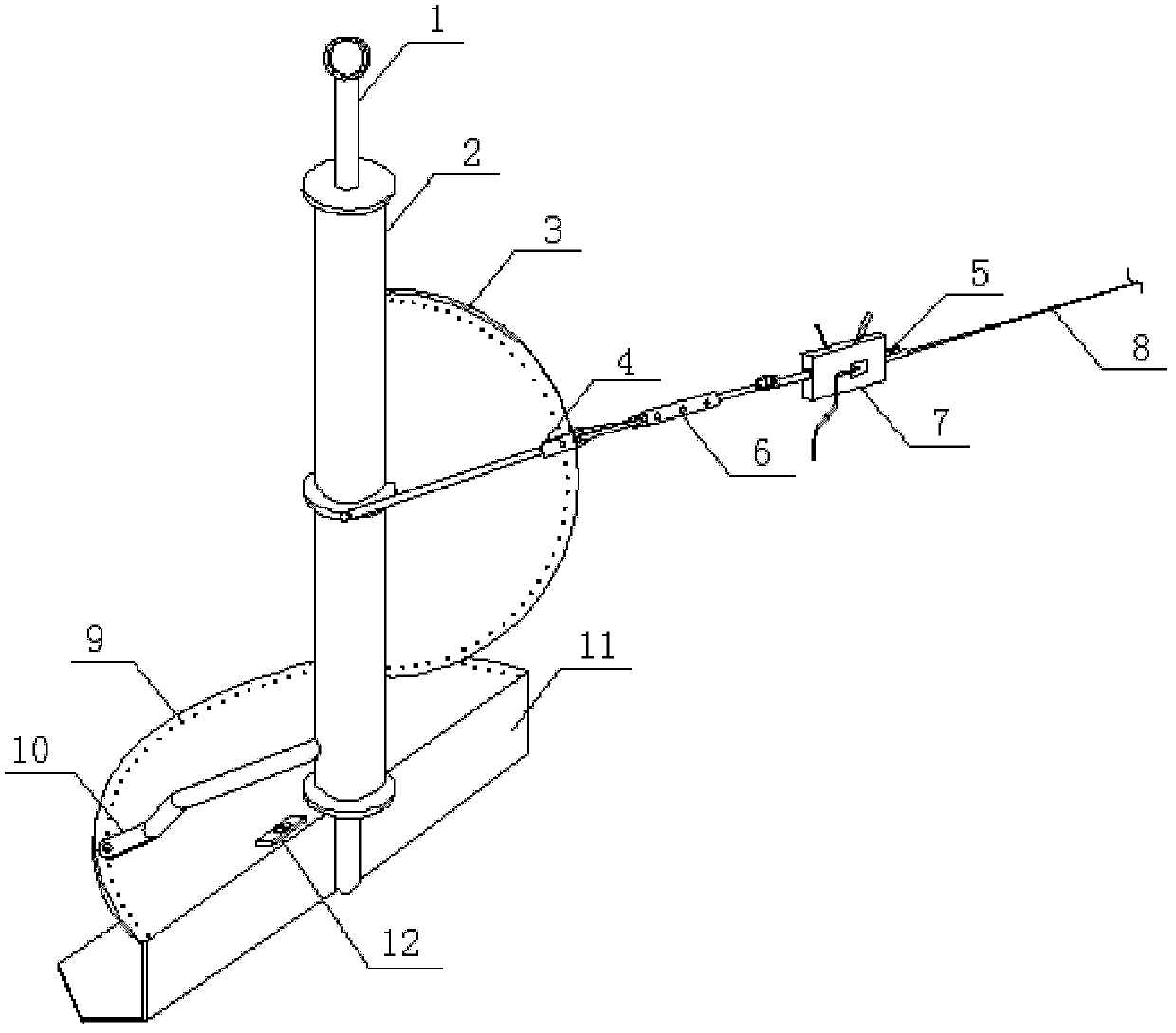

[0021] Such as figure 1 , figure 2 As shown, the method for measuring the spatial position of the flange of the submarine pipeline of the present invention, the first step is to install the spatial position measuring device A of the flange of the submarine pipeline at the flange B of the flat pipe end of the submarine pipeline, and install The space position measuring device A' of the flange of the submarine pipeline is installed at C; the second step is to connect the vertical distance between the space position measuring devices A and A' of the two submarine pipeline flanges through the distance measuring wire 8, the wire hoist 7 and the tensiometer 6. One end of the tensiometer 6 is connected with the vertical angle pointer of the submarine pipeline flange space position measuring device installed at a flange through a carabiner, and the other end is connected with one end of the wire hoist 7 through a snap ring. The other end of the gourd 7 is connected with one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com