Master valve body of electromagnetic four-way reversing valve and electromagnetic four-way reversing valve with adoption of same

A four-way reversing valve and electromagnetic technology, which is applied to valve details, valve devices, valve housing structures, etc., can solve the problems of long processing cycle, complicated process, and high manufacturing cost, so as to save processing time, simplify processing technology, and The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

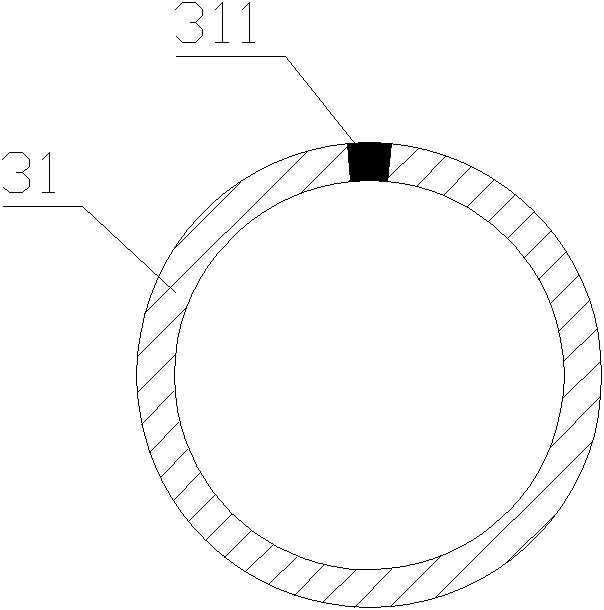

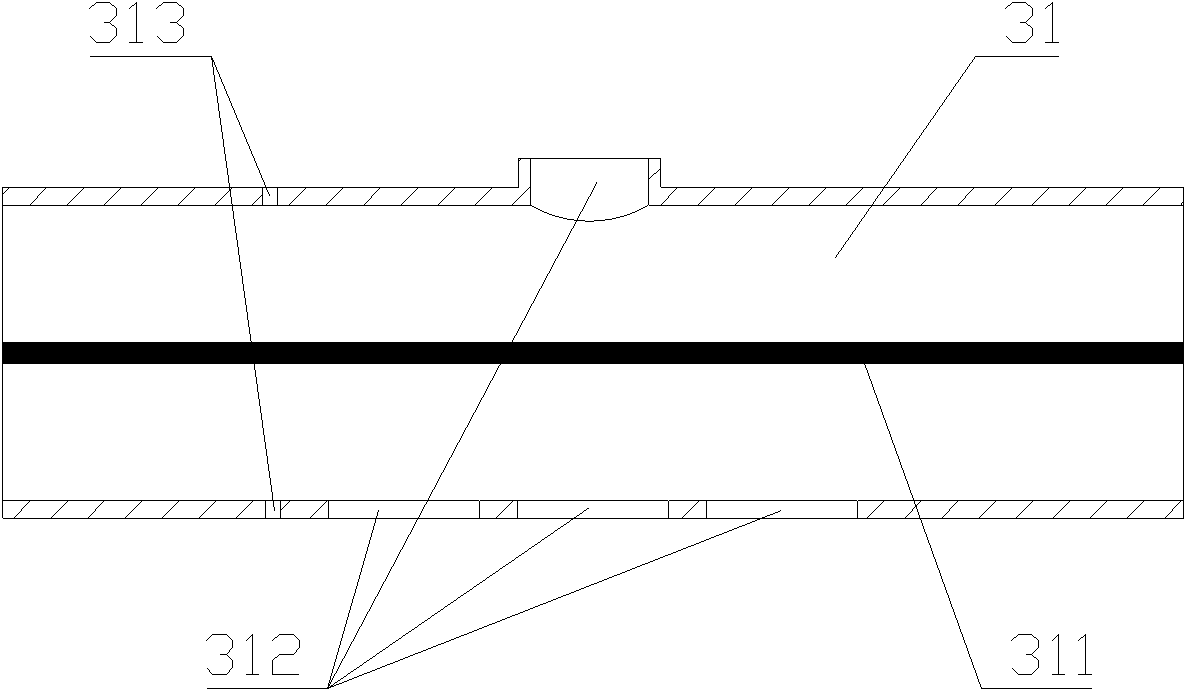

[0022] Such as figure 2 and 3 As shown, the embodiment of the main valve body of the electromagnetic four-way reversing valve of the present invention includes a valve tube 31, and the linear connecting seam 311 on the cylindrical tube is seamlessly processed after the valve tube is rolled into a cylindrical tube by a stainless steel plate. It is seam welded, and the valve tube is provided with a connection hole 312 and a capillary hole 313.

[0023] In the seamless welding process of the valve tube, a filling rod is provided in the cylindrical tube to improve the precision of the inner surface of the cylindrical tube and maintain the roundness of the cylindrical tube, and the filling rod is matched with the cylindrical tube. The filling rods are high temperature resistant ceramic rods or titanium rods, or can also be made of other high temperature resistant materials with a melting point exceeding 1600°C. Since in the prior art, the precision of the inner surface of the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com