High pressure resistant cylinder with approach switch

A technology of proximity switch and high pressure resistance, which is applied in the direction of fluid pressure actuation device, etc., which can solve the problems of large cylinder size, wide piston, and increased cylinder cost, so as to achieve precise and reliable control, reduce the probability of air leakage, and reduce the difficulty of processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

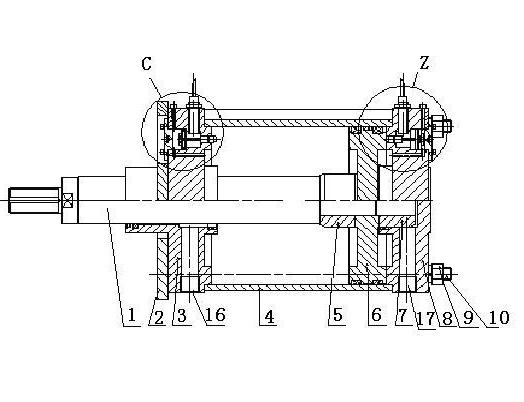

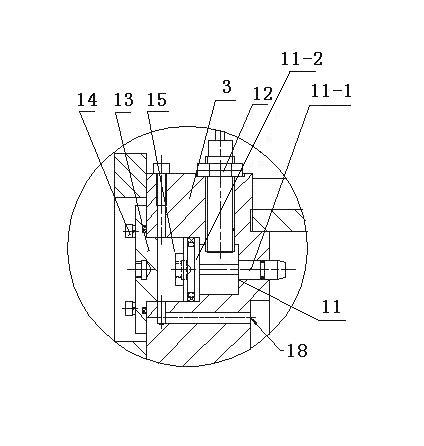

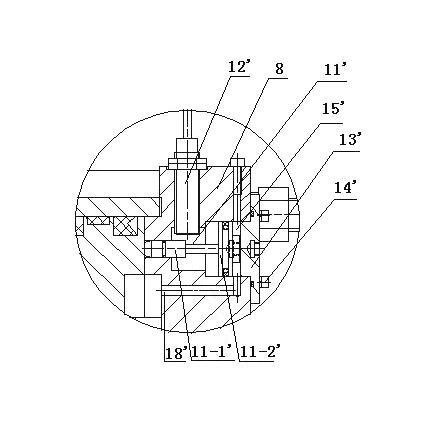

[0012] Embodiment: a kind of high pressure resistant cylinder with proximity switch (see figure 1 , figure 2 , image 3 ), it includes a cylinder 4, the cylinder 4 is connected to the front cover 3, the front cover 3 is provided with a front air inlet 16, the front cover 3 is connected to the flange 2, the cylinder 4 is provided with a piston rod 1, the piston rod 1 and the buffer sleeve 5. Piston 6 and buffer nut 7 are threaded together, cylinder 4 is connected to back cover 8, rear cover 8 is provided with rear air inlet 17, flange 2, front cover 3, cylinder 4, and back cover 8 are used The tie rod bolts 10 are connected together, and then tightened with hex nuts 9 to form a whole. The front cover 3 is connected to the first proximity switch 12 of the three-wire system PNP normally open, and the rear cover 8 is connected to the second proximity switch 12' of the three-wire system PNP normally open. The cover 8 is connected to the rear gland 13' through the second hexagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com