Compressor volute of split type turbosuperchager

A turbocharger and compressor technology, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve problems such as increasing production costs, and achieve the effect of convenient adjustment, cost reduction and number of models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

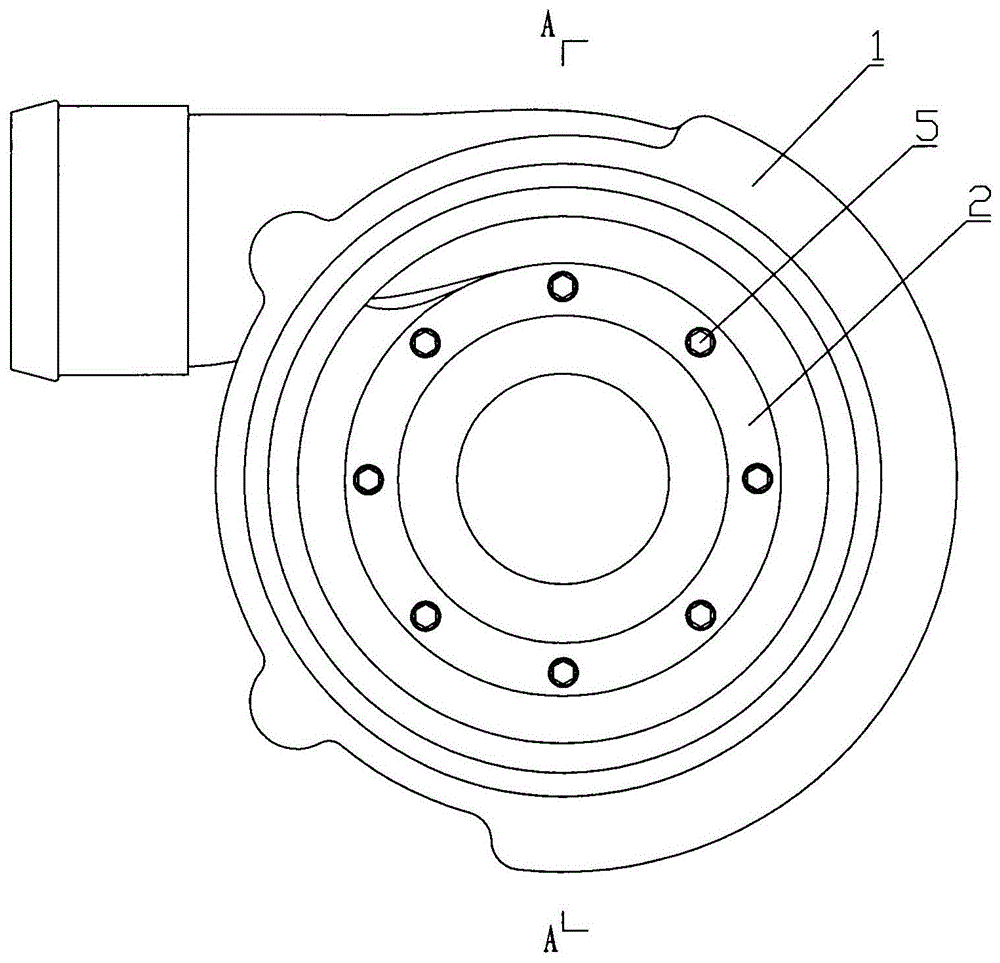

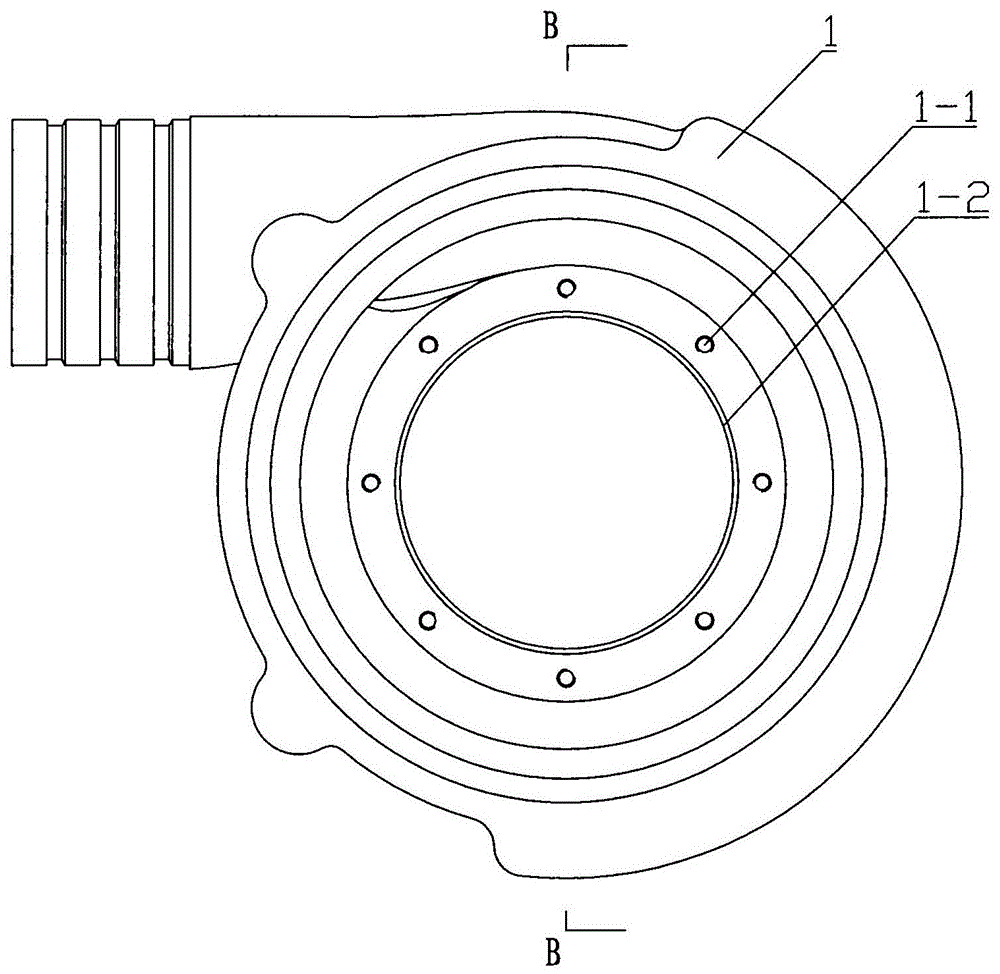

[0026] A split type turbocharger compressor volute, including a contour body 1 and a flow channel body 2.

[0027] The contour body 1 is provided with a threaded hole 1-1 and a conical hole 1-2 for fixing the flow channel body 2, and the conical hole 1-2 is provided with a first sealing groove 1-2-1 and a second sealing groove 1-2- 2.

[0028] The flow channel body 2 is provided with a pressure plate 2-1, a cone 2-2 matching with the conical hole 1-2 on the contour body 1 and a flow channel 2-3, and the pressure plate 2-1 is provided with a countersunk screw hole 2-1-1, the cone 2-2 is provided with the first sealing groove 2-2-1 matching the first sealing groove 1-2-1 and the second sealing groove 1-2-2 on the contour body 1 And the second sealing groove 2-2-2, the diameter of the pressure plate 2-1 is d, the width of the pressure plate 2-1 is h, and the diameter of the flow channel 2-3 is D1.

[0029] During installation, the flow channel body 2 is fastened in the contour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com