Light-colored cardanol alkyl ether epoxy curing agent and preparation method thereof

A cardanol alkyl ether, epoxy curing agent technology, applied in the direction of coating, can solve the problems of darkening, easy oxidation color, etc., and achieve the effect of improving toughness and good color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

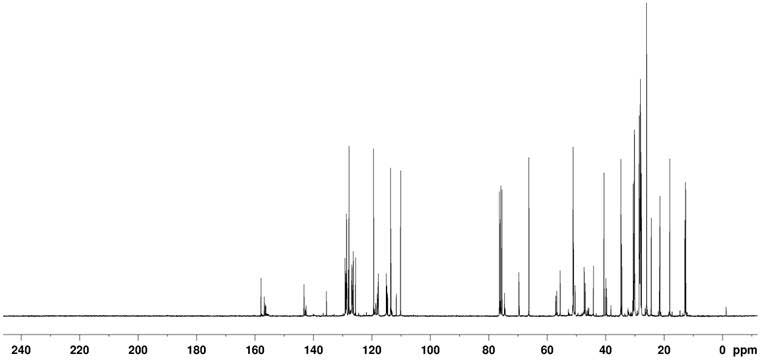

[0027] The preparation method of this light-colored cardanol alkyl ether epoxy curing agent is: 1 mole of cardanol alkyl ether and 1-3 moles of polyamines are mixed, then 1-3 moles of formaldehyde are added in batches, and the reaction temperature is controlled at React at 80-90°C for 4 hours, then heat up to 100-120°C to distill off the water generated by the reaction, and finally keep the temperature at 80-120°C and distill under reduced pressure until no water is evaporated, and then obtain cardanol alkyl ether through Mannich reaction epoxy curing agent.

[0028] In the preparation method of the above-mentioned light-colored cardanol epoxy curing agent, the structure of the cardanol alkyl ether used wherein is as follows:

[0029] where m is an integer from 0 to 22, and where n is 0, 1 or 2.

[0030] In the preparation method of the above-mentioned light-colored cardanol epoxy curing agent, wherein the polyamine used can be ethylenediamine, hexamethylenediamine, dihexyltr...

Embodiment 1

[0034] Mix 316g of cardanol methyl ether (1 mole, Nanjing Science and Technology Development Corporation of Institute of Forestry and Chemical Engineering) and 309g of diethylenetriamine (3 moles, Suzhou Xinxin Chemical Co., Ltd.) into a 2000 Add 243g of 37% formaldehyde solution (3 moles, Nanjing Chemical Reagent Factory) in batches within 0.5 hours, control the reaction temperature between 80-90°C for 4 hours, then raise the temperature to 100-120°C The water generated by the reaction was steamed under pressure, and the final temperature was kept at 80-120° C. under reduced pressure until no water was evaporated, and 207 g of water was evaporated. Obtain 641g of light yellow oily cardanol methyl ether epoxy curing agent, the amine value is 383mg / g, and the yield is 97%.

Embodiment 2

[0036] Mix 358 g of cardanol butyl ether (1 mole, Nanjing Science and Technology Development Corporation of Forestry Institute), 189 g of tetraethylenepentamine (1 mole, Hangzhou Jiaxing Chemical Co., Ltd.) In a three-neck flask, add 30g of paraformaldehyde (1 mole, Nanjing Chemical Reagent Factory) in batches within 0.5 hours, control the reaction temperature between 80-90°C for 4 hours, then heat up to 100-120°C and steam under normal pressure. The water generated by the reaction was removed, and the final temperature was kept at 80-120° C. and distilled under reduced pressure until no water was evaporated, and 69 g of water was distilled out. Obtain 537g of light yellow oily cardanol butyl ether epoxy curing agent, the amine value is 481mg / g, and the yield is 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com