Bridged diamidino titanium metal catalyst, and preparation method and application thereof

A catalyst, titanium metal technology, applied in the direction of titanium organic compounds, etc., can solve the problems of harsh catalyst storage conditions, low catalyst total yield, unsuitable preparation of raw materials, etc., and achieve the effects of low price, high yield and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

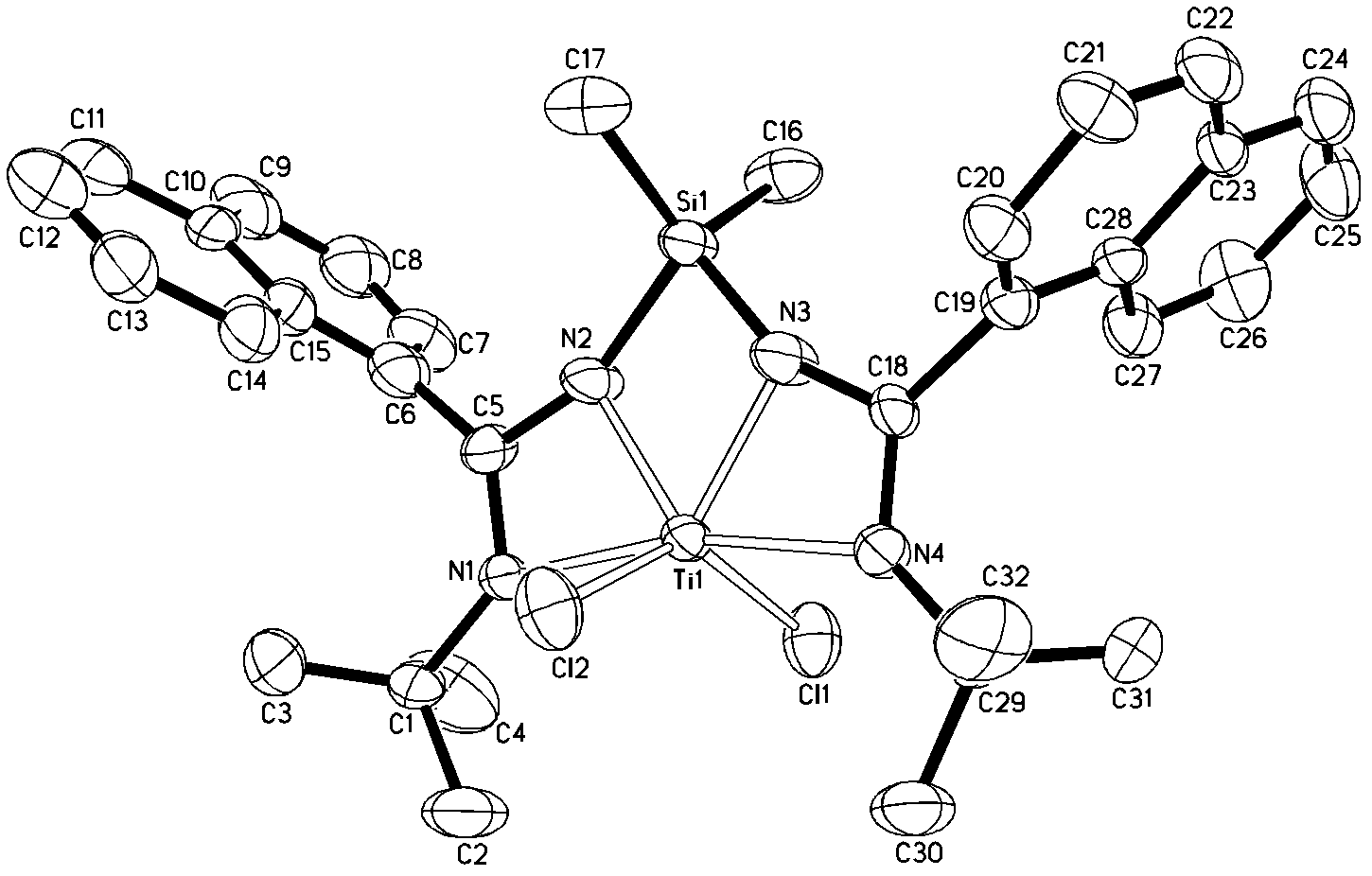

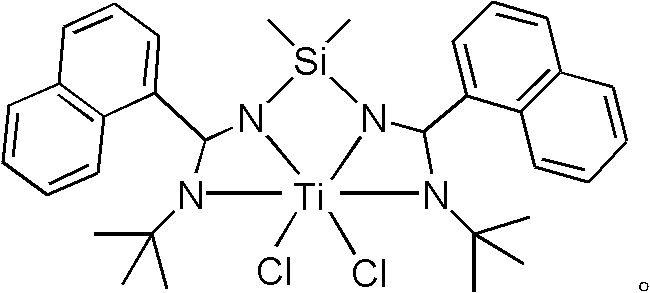

[0017] Preparation and characterization of embodiment 1 catalyst

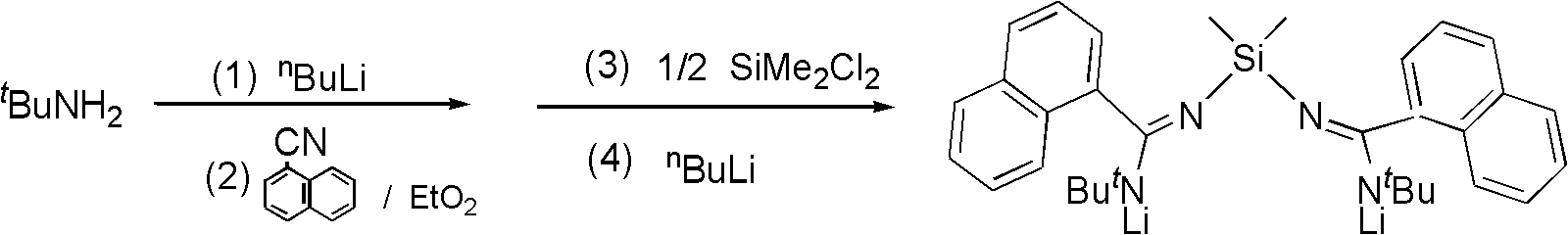

[0018] (1) Preparation of Lithium Salt of Bridged Diamidino Ligand

[0019] Under the protection of nitrogen and ice-water bath, tert-butylamine (1.01ml, 9.52mmol) was dissolved in diethyl ether (30cm 3 ), under stirring, slowly add butyllithium in n-hexane solution (2.2mol dm -3 , 4.3cm 3 , 9.52mmol), continued to stir for 3 hours, cooled the reaction solution to 0°C in an ice-water bath, and added 1-naphthonitrile (1.31cm 3 , 9.52mmol), continued to stir for 6 hours, then cooled the reaction solution to 0°C, added dichlorodimethylsilane (0.58cm 3 , 4.76mmol), filtered after reacting for 6 hours, the obtained solution was cooled to 0°C, and a n-hexane solution of butyllithium (2.2mol dm -3 , 4.3cm 3 , 9.52mmol), stirred for 3 hours, concentrated and crystallized to obtain a colorless crystal-like bridged bisamidinyl ligand lithium salt;

[0020] (2) Dissolve the bridged bisamidinyl ligand lithium salt (0...

Embodiment 2

[0024] 1. The preparation of catalyst is the same as in Example 1.

[0025] 2. Ethylene polymerization: Vacuumize a 250 ml stainless steel kettle equipped with a mechanical stirrer and a thermocouple, replace it with nitrogen for 3 times, and then replace it with ethylene for 2 times. After heating up to 50°C, add catalyst (4.4mg, 5μmol) in toluene solution and a certain amount of toluene in sequence, then add methylaluminoxane (1.67mol / L, 4.5ml) to make Al / Zr=1500, and finally add a certain amount of Measure the total volume of toluene to 100 mL. The ethylene pressure was immediately raised to 10 atm and stirred vigorously at 50°C for 30 minutes. The reaction solution was poured out, neutralized by adding 5% hydrochloric acid ethanol solution, and a white solid was precipitated. Filter and dry naturally. Obtained product 0.0412 g, polymerization activity: 1.65×10 4 g mol(Zr) -1 h -1 .

Embodiment 3

[0027] 1. The preparation of catalyst is the same as in Example 1.

[0028]2. Ethylene polymerization: Vacuumize a 250 ml stainless steel kettle equipped with a mechanical stirrer and a thermocouple, replace it with nitrogen for 3 times, and then replace it with ethylene for 2 times. After heating up to 50°C, add catalyst (4.0mg, 5μmol) in toluene solution and a certain amount of toluene in sequence, then add methylaluminoxane (1.67mol / L, 6.0ml) to make Al / Zr=2000, and finally add a certain amount of Measure the total volume of toluene to 100 mL. The ethylene pressure was immediately raised to 10 atm and stirred vigorously at 50°C for 30 minutes. The reaction solution was poured out, neutralized by adding 5% hydrochloric acid ethanol solution, and a white solid was precipitated. Filter and dry naturally. Obtained product 0.0740 g, polymerization activity: 2.96×10 4 g mol(Zr) -1 h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com