Aluminum titanate powder prepared by taking metal aluminum as aluminum source through non-hydrolytic sol-gel process at low temperature and preparation method thereof

A technology of aluminum titanate powder and metal aluminum, which is applied in the field of aluminum titanate powder prepared by non-hydrolytic sol-gel process at low temperature and its preparation, can solve problems such as difficult storage, high synthesis temperature, and complicated control process, and achieve Low cost, easy storage and weighing, and the effect of improving the synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

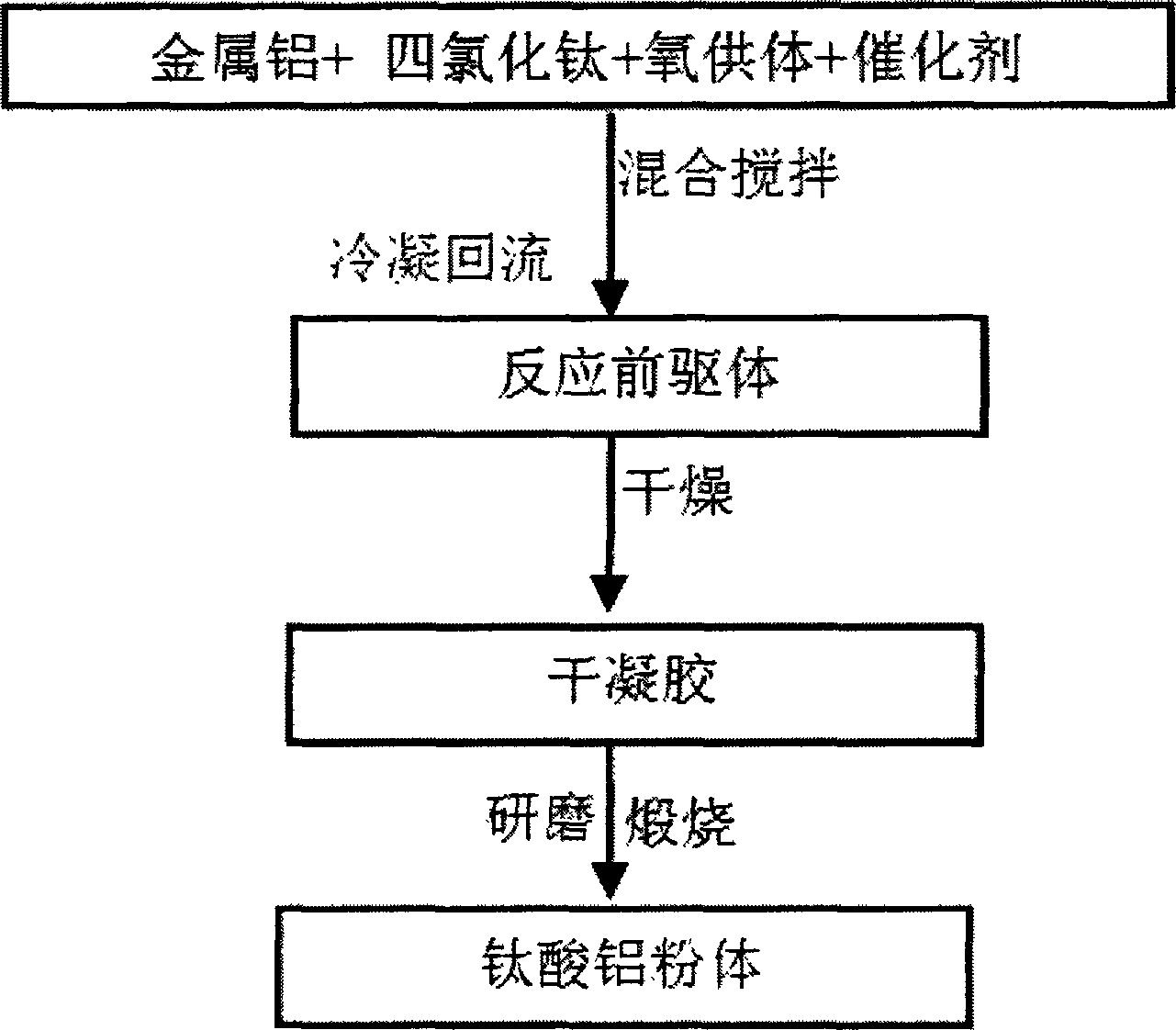

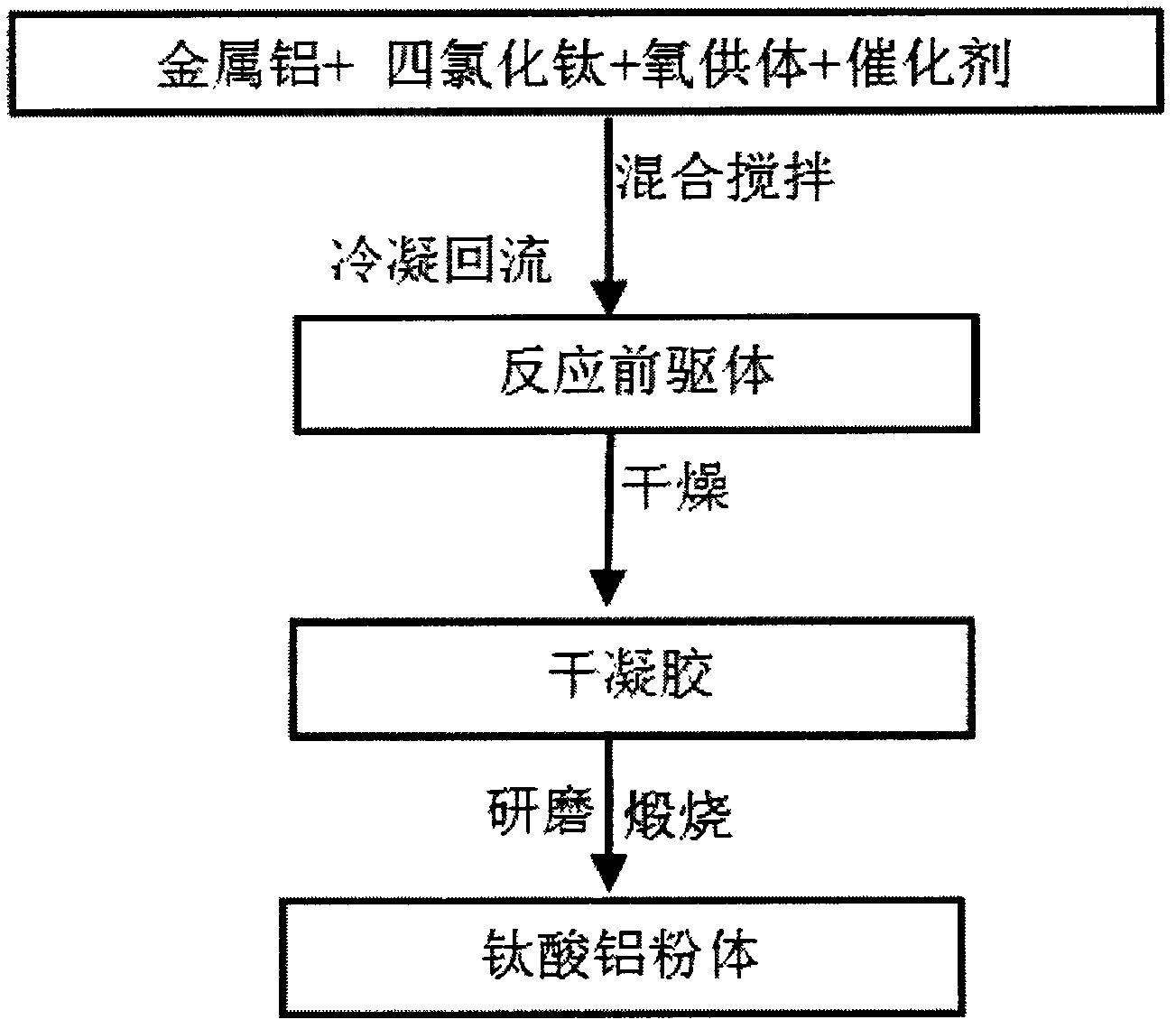

Method used

Image

Examples

Embodiment 1

[0018] Weigh 1.9683g of aluminum powder and put it into a dry Erlenmeyer flask filled with 22ml of absolute ethanol, use a pipette to measure 4ml of titanium tetrachloride according to the stoichiometric ratio of aluminum titanate and slowly drop it into the Erlenmeyer flask, then add 0.59g ferric chloride, after vigorous stirring, put the Erlenmeyer flask into an 80°C oil bath, condense and reflux for 7 hours to obtain an aluminum titanate precursor mixture, and obtain an aluminum titanate xerogel powder after 3 hours of infrared drying. The dry gel powder is ground and heat-treated at 750° C. for 30 minutes to obtain the aluminum titanate powder of the present invention.

Embodiment 2

[0020] Weigh 1.9683g of aluminum powder and put it into a dry Erlenmeyer flask filled with 22ml of absolute ethanol, use a pipette to measure 4ml of titanium tetrachloride according to the stoichiometric ratio of aluminum titanate and slowly drop it into the Erlenmeyer flask, then add 0.95g of aluminum chloride, after vigorous stirring, the conical flask was placed in an oil bath at 110°C, condensed and refluxed for 15 hours to obtain an aluminum titanate precursor mixture, and after 3 hours of infrared drying to obtain an aluminum titanate xerogel powder. The dry gel powder is ground and heat-treated at 750° C. for 60 minutes to obtain the aluminum titanate powder of the present invention.

Embodiment 3

[0022] Weigh 1.9683g of aluminum powder and put it into a dry Erlenmeyer flask filled with 24ml of anhydrous isopropanol, and slowly drop 4ml of titanium tetrachloride into the Erlenmeyer flask according to the stoichiometric ratio of aluminum titanate with a pipette. Then add 0.1 g of iodine, stir vigorously, put the Erlenmeyer flask into an oil bath at 130° C., condense and reflux for 24 hours to obtain an aluminum titanate precursor mixture, and obtain an aluminum titanate xerogel powder after 3 hours of infrared drying. The dry gel powder is ground and heat-treated at 750° C. for 60 minutes to obtain the aluminum titanate powder of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com