Blister tray for inner packing of bearing

A technology of inner packaging and shallow trays, which is applied in the field of accessories for new circulation containers, can solve the problems of anti-rust oil accumulation and failure to meet the impact resistance requirements of bearing product packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners in the present invention will be further described in detail below in conjunction with the accompanying drawings.

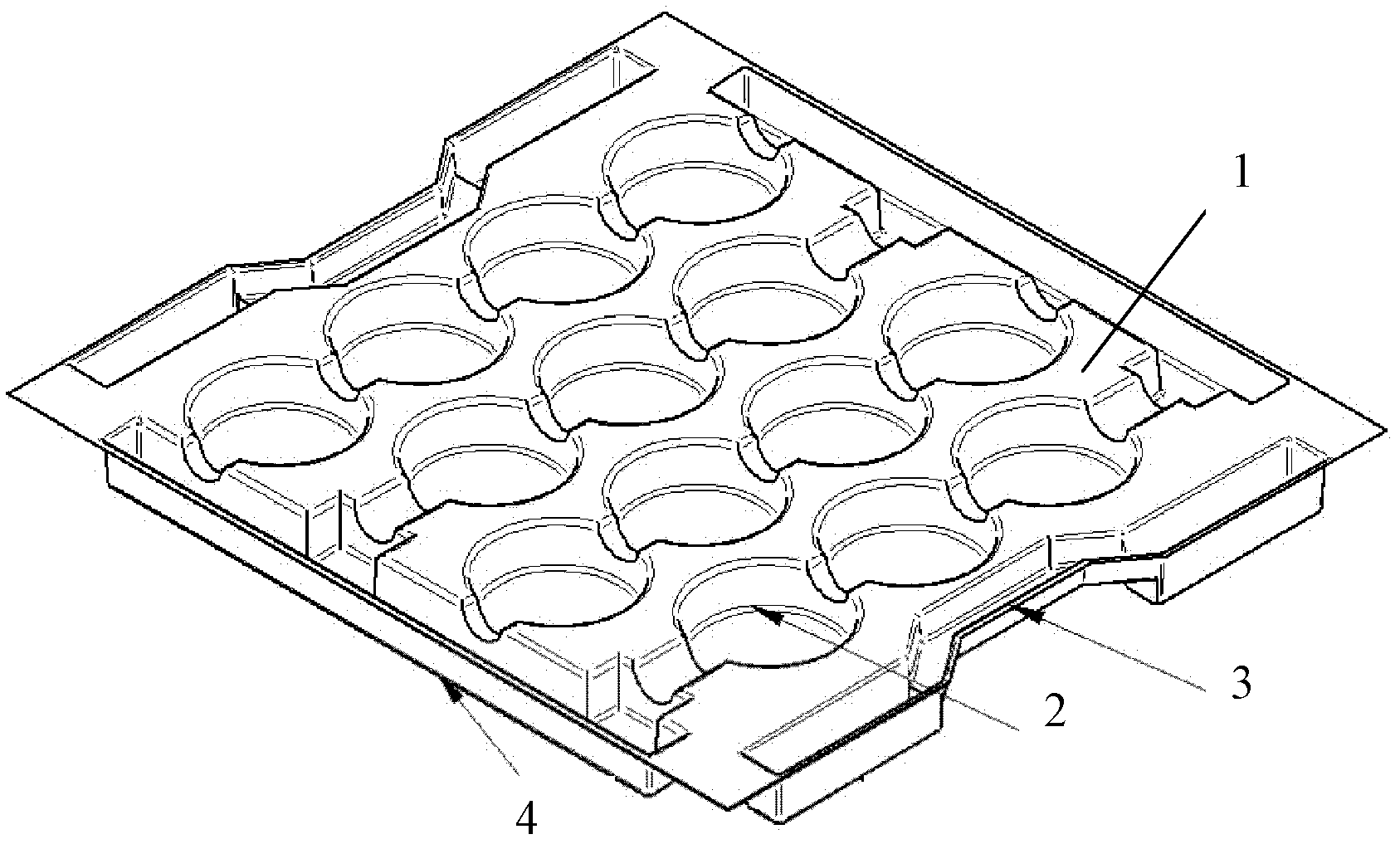

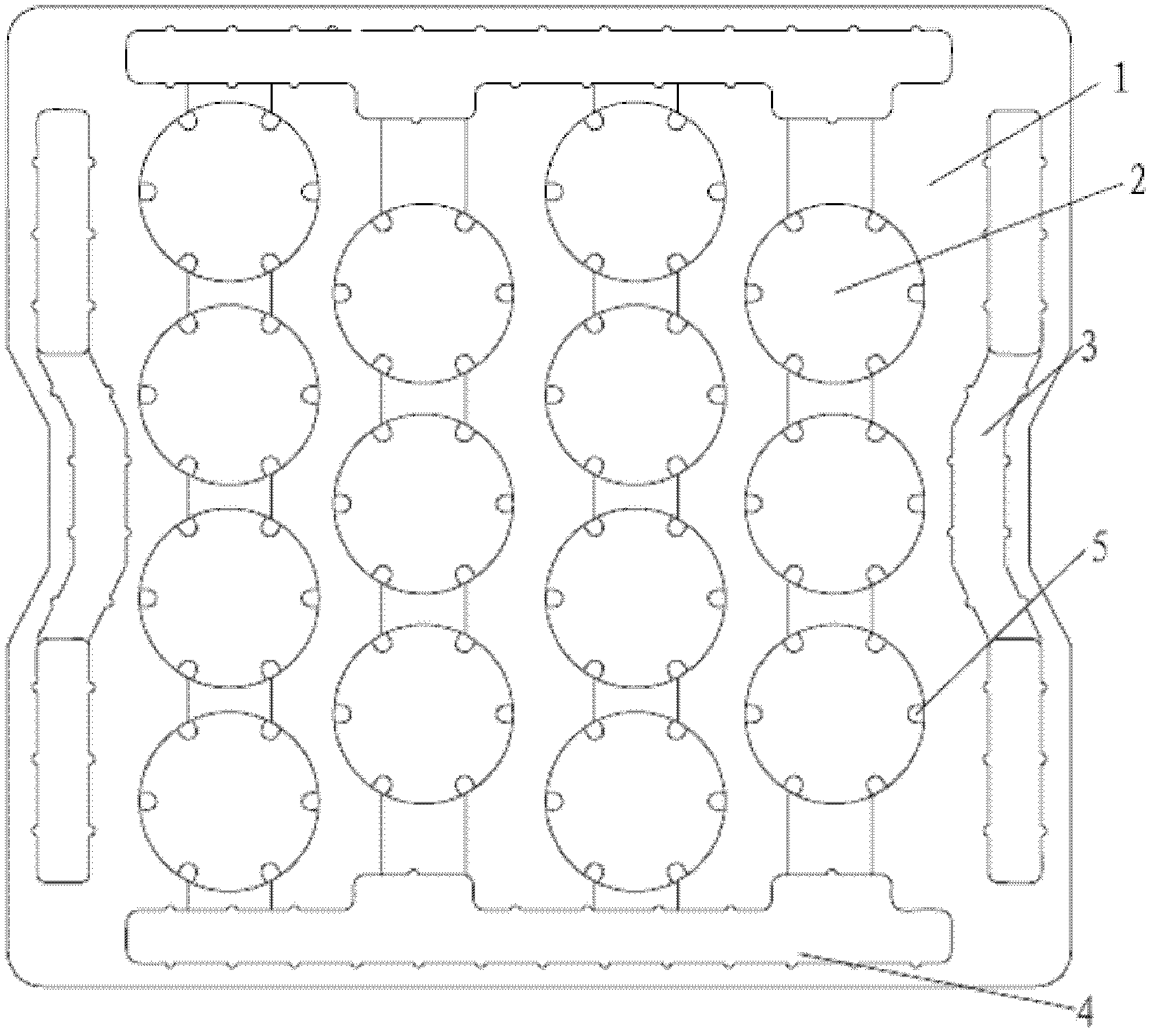

[0015] Such as figure 1 As shown, the general shape of the blister platter in the present invention is rectangular, and there are many small circular platters 2 distributed in the main body 1 inside it for placing bearings. The circular platters 2 in the present invention are distributed in odd and even alternately between every two rows, that is, they are distributed in a staggered manner, which is conducive to the products in the previous platter not being directly pressed against the products in the next platter when the platters are stacked, so that The platter is less loaded and better protects the product.

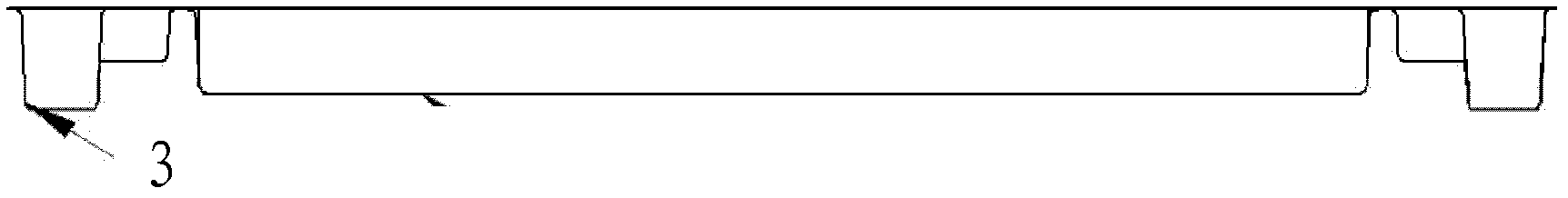

[0016] Such as figure 1 and figure 2 , image 3 As shown, the blister tray is provided with a concave handle 3 on a pair of both sides, and the handle 3 can facilitate the worker to pack the blister tray i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com