Deburring method based on heat energy

A thermal energy deburring and deburring technology, which is applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problem that the internal burrs of complex parts cannot be removed, and achieve good deburring quality, small volume, and large surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The invention provides a method for thermal energy deburring, the steps of which are:

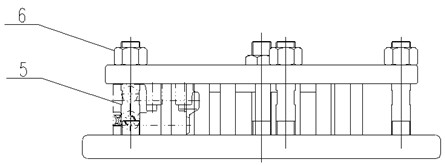

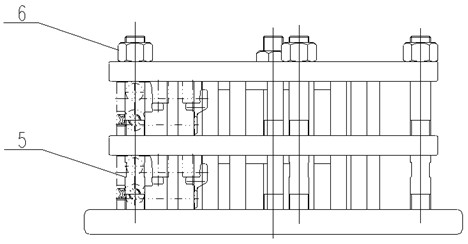

[0023] Step 1, place the part 7 to be processed on the fixture, wherein, such as figure 1 and figure 2 As shown, the fixture includes a base plate 1, and the parts to be processed 7 are placed on the base plate 1. The parts to be processed 7 are arranged around the central axis of the base plate 1, and a first screw 4 is respectively arranged on both sides of each part to be processed 7. A screw 4 limits the left and right of the part 7 to be processed. The first screw 4 is fixed on the base plate 1. The two ends of the part 7 to be processed are respectively pressed and fixed by the pressure ring 2 and the pressure plate 3. The bottom plates 1 are fixedly connected by the first screw rod 5 and the nut 6 .

[0024] The design and processing of the fixture are relatively simple. All the parts in the fixture are made of heat-resistant stainless steel. When designing, it is only nece...

Embodiment 2

[0030] The difference between this embodiment 1 and embodiment 2 is that in step 3, the mixed gas of methane and oxygen is passed into the airtight container, and the part 7 to be processed is made of QT500-7 material. Therefore, the feeding pressure of methane is 3bar, the inlet pressure of oxygen is 3bar. Other steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com