Preparation method for natural calcium base porous solid alkaline catalyst for catalysis in interesterification

A solid base catalyst, transesterification technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low activity, poor catalytic performance and small specific surface area And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

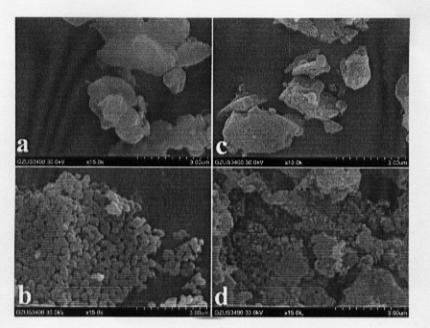

[0015] Example 1: Preparation of roasted porous calcite and its application in catalytic preparation of jatropha seed oil biodiesel

[0016] 1. Catalyst preparation: Take 100 g of calcite powder and 600 g of stearic acid, mix them and stir at 170°C for 1 hour. Pour it into a crucible while it is hot, bake it at 850°C for 1 hour under air flow, and grind it for later use after cooling.

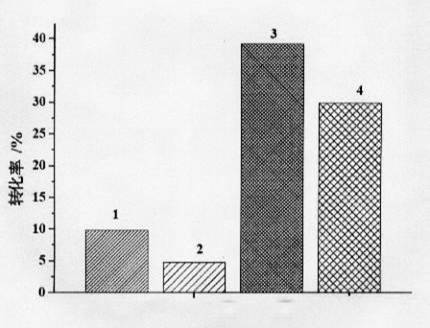

[0017] 2 Application in the catalytic preparation of jatropha seed oil biodiesel: Weigh 50g of jatropha seed oil, add 17.3g of methanol, add roasted porous calcite with an oil mass of 3 wt.%, and reflux and stir for 2h. The product was filtered, vacuum distilled to recover methanol, cooled, and centrifuged to obtain 44.0 g of biodiesel product, in which the fatty acid methyl ester content reached 98.0 wt.%.

[0018]

Embodiment 2

[0019] Example 2: Preparation of roasted porous dolomite and its application in the catalytic preparation of caper seed oil biodiesel

[0020] 1. Catalyst preparation: Take 100 g of dolomite powder and 1200 g of stearic acid, mix them and stir at 100°C for 3 hours. Pour it into a crucible while it is hot, and bake it at 800°C for 3 hours under air flow. After cooling, grind it for later use.

[0021] 2. Application in catalytic preparation of caperia seed oil biodiesel: Weigh 50g caperia seed oil, add 13.6g methanol, add roasted porous calcite with 4 wt.% oil mass, reflux and stir for 3h. The product was filtered, vacuum distilled to recover methanol, cooled, and centrifuged to obtain 45.6 g of biodiesel product, in which the fatty acid methyl ester content reached 98.5 wt.%.

[0022]

Embodiment 3

[0023] Example 3: Preparation of Roasted Porous Egg Shells / Crab Shells and Its Application in the Catalytic Preparation of Sapius Oil Biodiesel

[0024] 1. Catalyst preparation: Take 50g of washed and dried egg shell and crab shell powder, 120g of lauric acid, mix and stir at 300°C for 0.2h. Pour it into a crucible while it is hot, bake it at 700°C for 2 hours under air flow, and grind it for later use after cooling.

[0025] 2. Application in catalytic preparation of tallow catalpa oil biodiesel: Weigh 50g of tallow catalpa oil, add 19.3g of methanol, add roasted porous egg shell / crab shell with 4 wt.% of oil mass, reflux and stir for 3h. The product was filtered, vacuum distilled to recover methanol, cooled, and centrifuged to obtain 43.9g of biodiesel product, in which the fatty acid methyl ester content reached 98.2wt.%.

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com