Flat plate pressure rubbing type millet thresher

A thresher and millet technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of high crushing rate and low cleaning rate, so as to reduce the breaking rate, reduce the time of kneading, and improve the cleaning rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

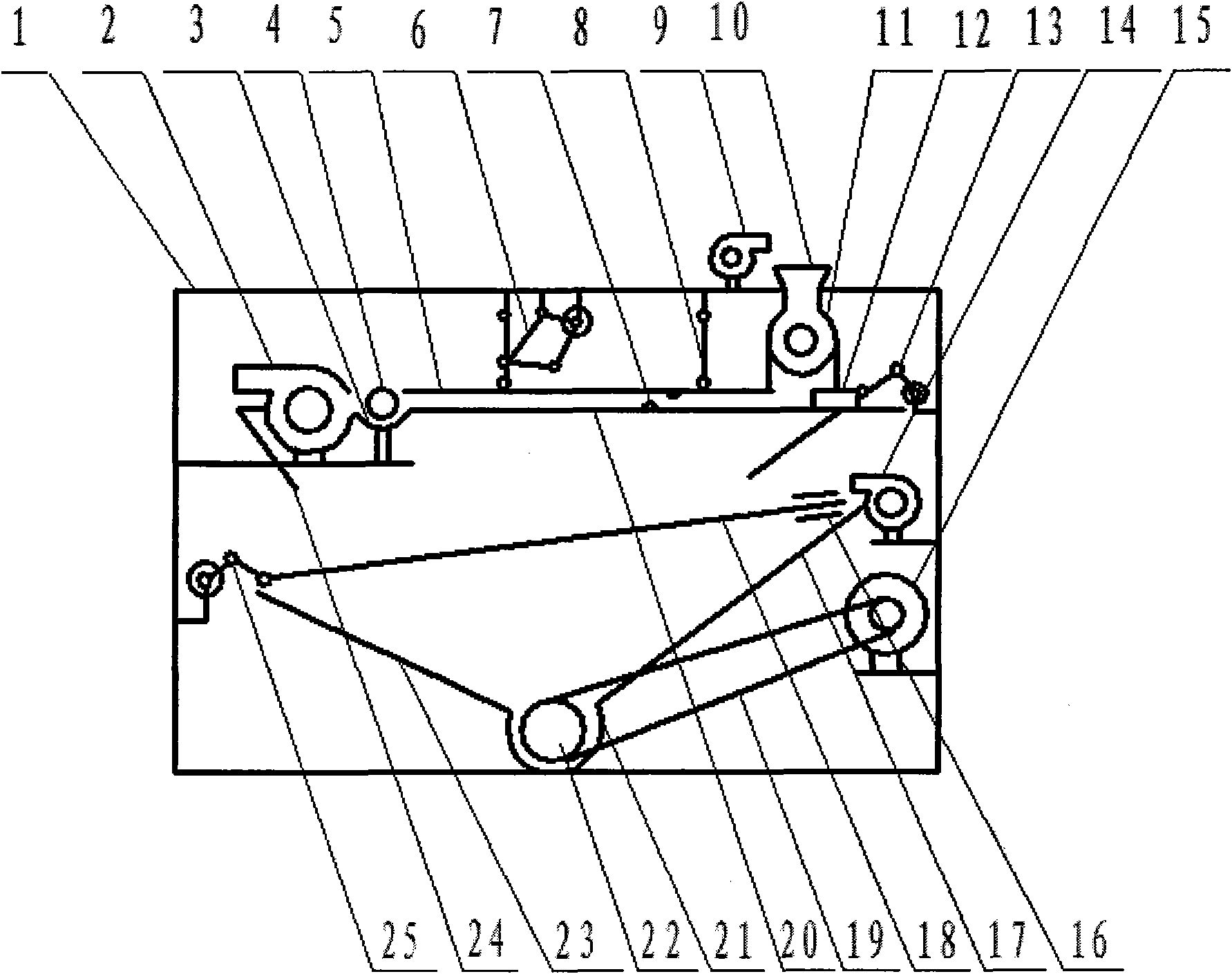

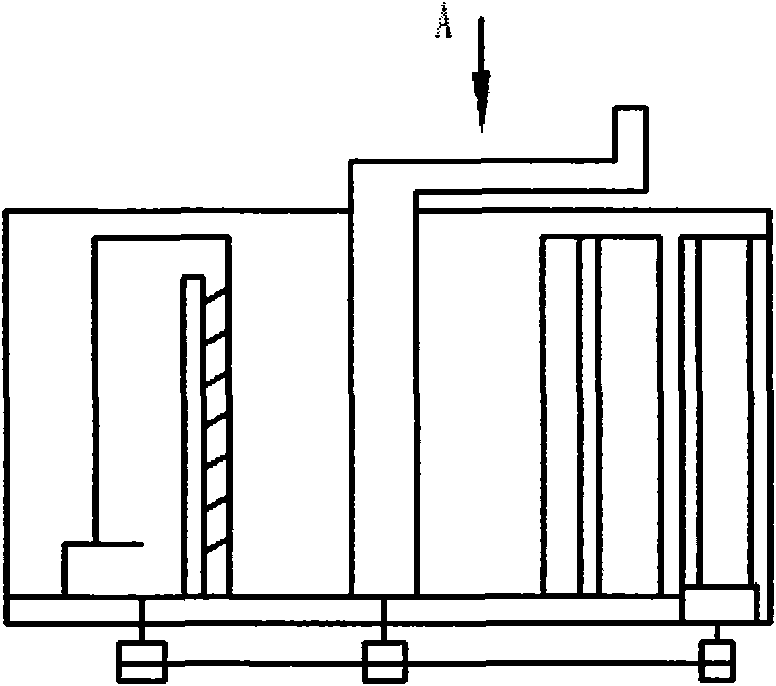

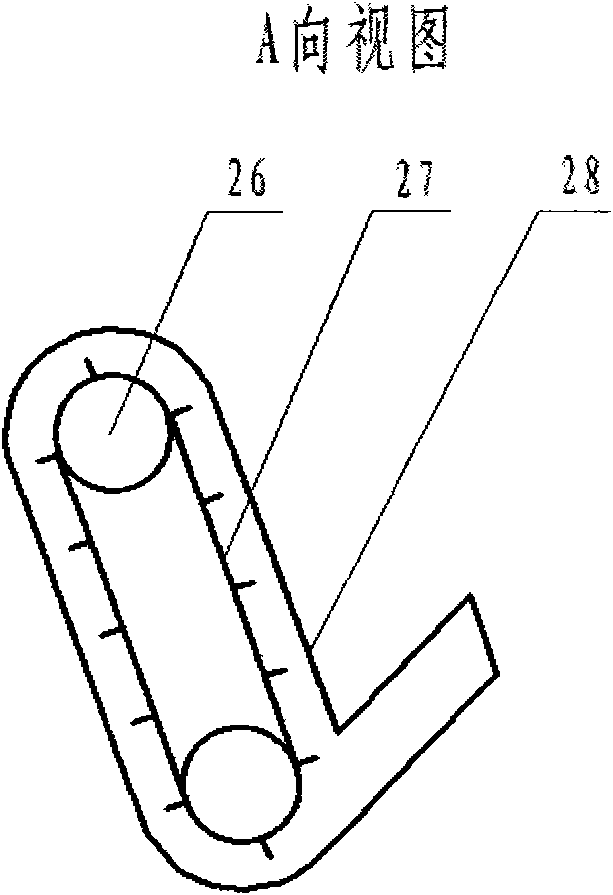

[0014] A kind of plate pressing millet threshing machine, which is composed of frame 1, secondary roller rubbing combination 2, secondary rubbing cover 2-1, secondary rubbing roller 2-2, secondary rubbing concave panel 2-3, secondary Kneading roller shaft 2-4, secondary kneading pulley 2-5, ear code conveyor concave plate 3, ear code conveyor 4, movable grain rubbing plate 5, rocker mechanism 6, arc straight rack 7, connecting rod Mechanism 8, feeding port fan 9, hopper 10, primary roller kneading combination 11, primary kneading roller 11-1, primary kneading roller cutter 11-2, primary kneading concave panel 11-3, primary kneading roller shaft 11-4, primary kneading roller pulley 11-5, ear pusher 12, ear pusher crank linkage mechanism 13, cleaning fan 14, motor 15, grain sieve track 16, right sliding grain plate 17, grain sieve 18, Transmission system 19, fixed grain rubbing plate 20, grain conveyer concave panel 21, grain conveyer 22, left side slides grain plate 23, gathers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com