Silver-based inorganic antibacterial agent and method for producing same, and antibacterial-treated product

A technology of an inorganic antibacterial agent and a manufacturing method, which is applied in the directions of bactericides, inorganic chemistry, antibacterial drugs, etc., can solve the problems of unsustainability and fast dissolution rate of silver ions, and achieve the effect of excellent water resistance and sustainability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

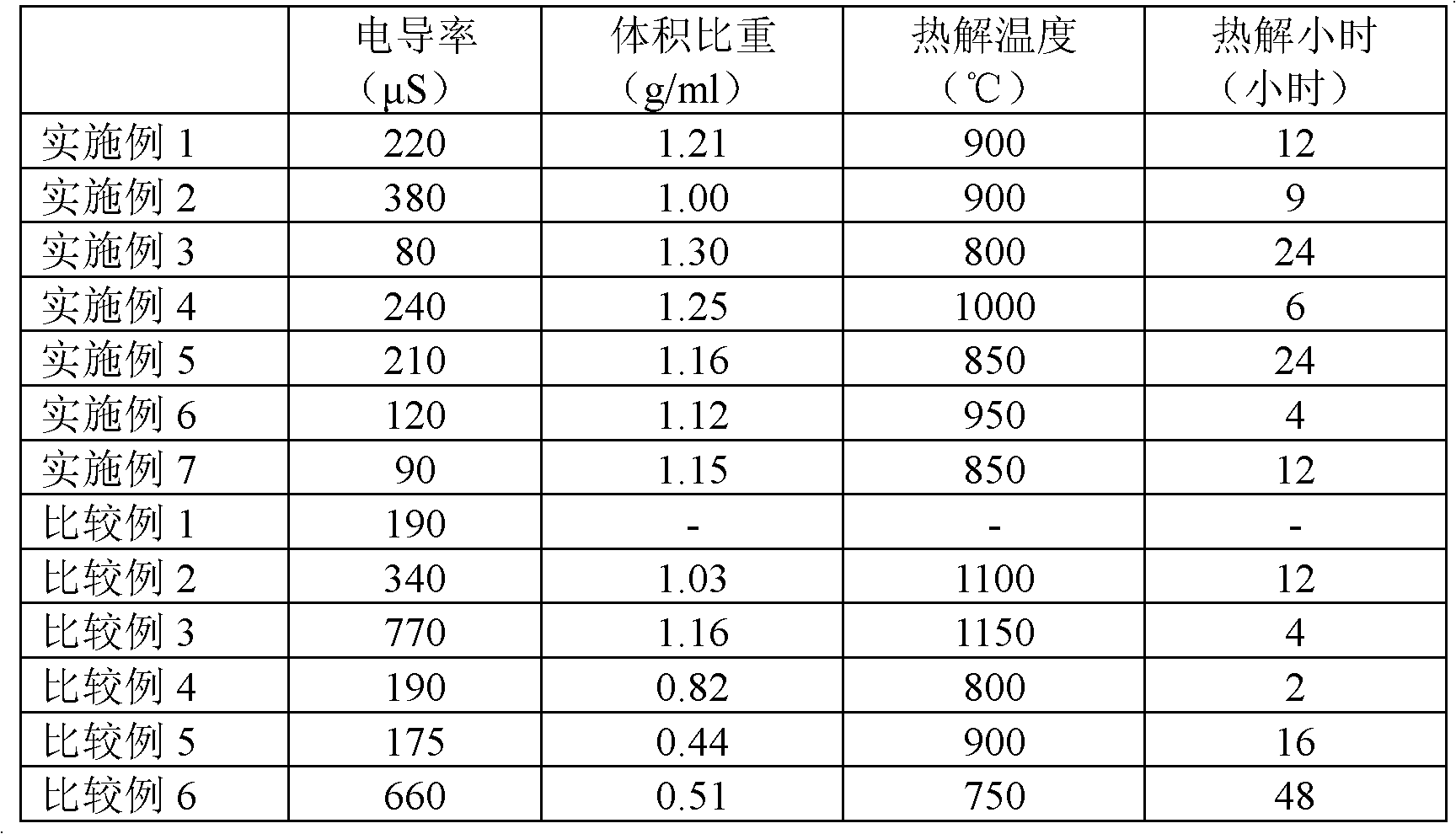

[0130] In 300 ml of deionized water, 0.1 mol of oxalic acid dihydrate, 0.2 mol of zirconium oxychloride octahydrate containing 0.17% hafnium, and 0.05 mol of ammonium chloride were dissolved, and then 0.3 mol of phosphoric acid was added with stirring. After adjusting pH to 2.6 using 20% sodium hydroxide aqueous solution in this solution, it stirred at 98 degreeC for 14 hours. Then, the obtained precipitate was carefully washed and dried at 120° C., whereby a zirconium phosphate compound was synthesized.

[0131] The amount of each component of this zirconium phosphate was measured, and the composition formula was as a result

[0132] Na 0.6 (NH 4 ) 0.4 Zr 1.98 f 0.02 (PO 4 ) 3 0.09H 2 O.

[0133] 450 ml of an aqueous solution of deionized water in which 0.05 mol of silver nitrate was dissolved was added to 0.09 mol of the obtained zirconium phosphate, and silver was supported by stirring at 60° C. for 2 hours. The silver-loaded slurry was filtered and washed with ...

Embodiment 2

[0139] Using zirconium phosphate having the following composition formula obtained in Example 1, the steps after the silver loading treatment step were changed as follows.

[0140] Na 0.6 (NH 4 ) 0.4 Zr 1.98 f 0.02 (PO 4 ) 3 0.09H 2 o

[0141] 450 ml of an aqueous solution in which 0.05 mol of silver nitrate was dissolved in deionized water was added to 0.09 mol of zirconium phosphate, and stirred at 60° C. for 2 hours to support silver. The slurry after carrying the processed silver was filtered and washed until the conductivity of the filtrate was 380 μS, and the solid content was adjusted to a volume specific gravity of 1.00 by drying at 120° C.

[0142] The composition formula obtained by measuring the amount of each component of the dry solid content composed of the silver-loaded zirconium phosphate is as follows.

[0143] Ag 0.55 Na 0.05 h 0.55 Zr 1.98 f 0.02 (PO 4 ) 3 0.14H 2 o

[0144] Furthermore, pyrolysis was performed by treating this dried produc...

Embodiment 3

[0147] Using zirconium phosphate having the following composition formula obtained in Example 1, the steps after the silver loading treatment step were changed as follows.

[0148] Na 0.6 (NH 4 ) 0.4 Zr 1.98 f 0.02 (PO 4 ) 3 0.09H 2 o

[0149] 450 ml of an aqueous solution in which 0.05 mol of silver nitrate was dissolved in deionized water was added to 0.09 mol of zirconium phosphate, and silver was supported by stirring at 60° C. for 2 hours. The slurry after carrying the treated silver was filtered and washed with water until the conductivity of the filtrate was 240 μS, and the solid content was adjusted to a volume specific gravity of 1.25 after drying at 120° C.

[0150] The composition formula obtained by measuring the amount of each component of the dry solid content composed of the silver-loaded zirconium phosphate is as follows.

[0151] Ag 0.55 Na 0.35 h 0.25 Zr 1.98 f 0.02 (PO 4 ) 3 0.11H 2 o

[0152] Furthermore, pyrolysis was performed by treatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com