Highly-accelerated stress screening (HASS) method of anti-skidding brake control box of aircraft

A high-acceleration stress, anti-skid braking technology, applied in measuring devices, instruments, measuring electricity and other directions, can solve the problems of high missed detection rate, unreal data, hidden troubles, etc., to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

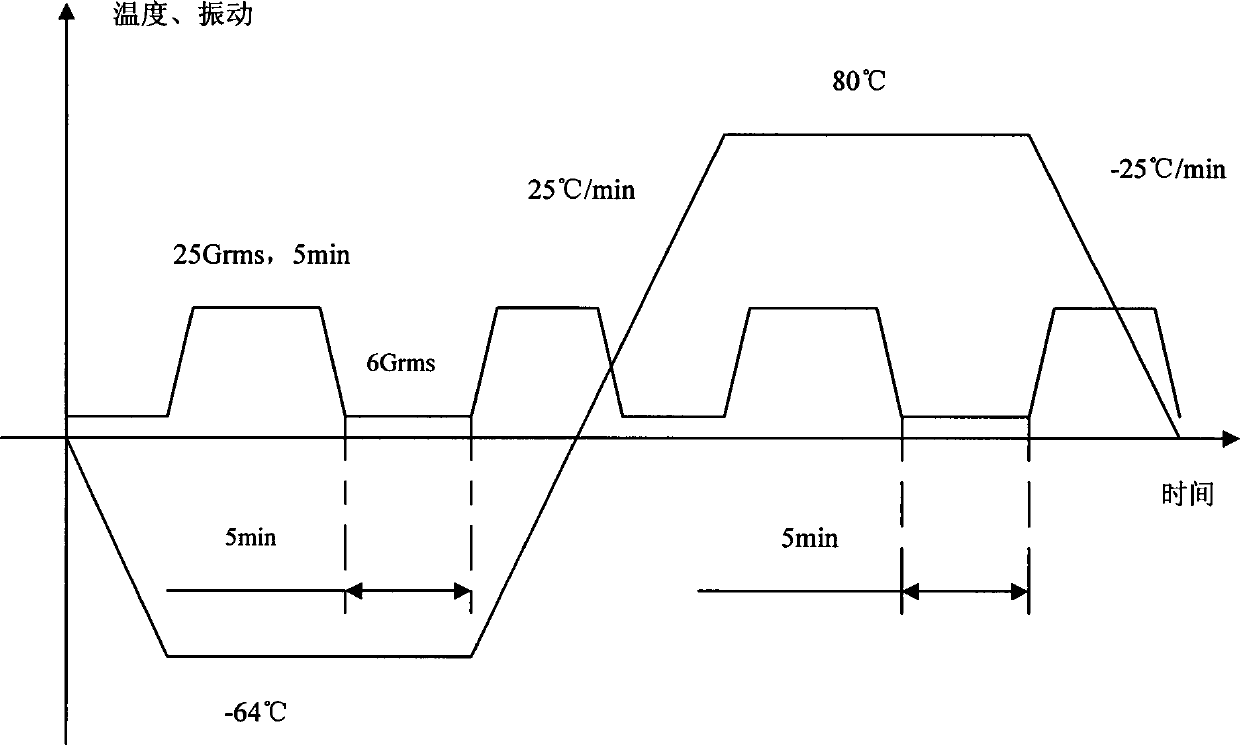

Embodiment 1

[0053] The test of this embodiment uses a reliability enhancement test box model UHS1200, a digital multimeter, a signal source and an oscilloscope. The number of control boxes in this embodiment is 2 sets, one set is used to verify the validity of the test profile, and the other set is used to verify the safety of the test profile.

[0054] This implementation example includes the following steps.

[0055] Step 1, determine the low temperature working stress limit of the control box

[0056] When determining the low temperature working stress limit of the control box, the low temperature stress is applied to the control box step by step from 20°C to determine the low temperature working stress limit of the control box. The step size of applying low temperature stress is 2°C, and the cooling rate is -25°C / min. Each time the temperature reaches the specified value, keep it for 5 minutes. Allow time for the temperature balance of the control box, and then perform the performanc...

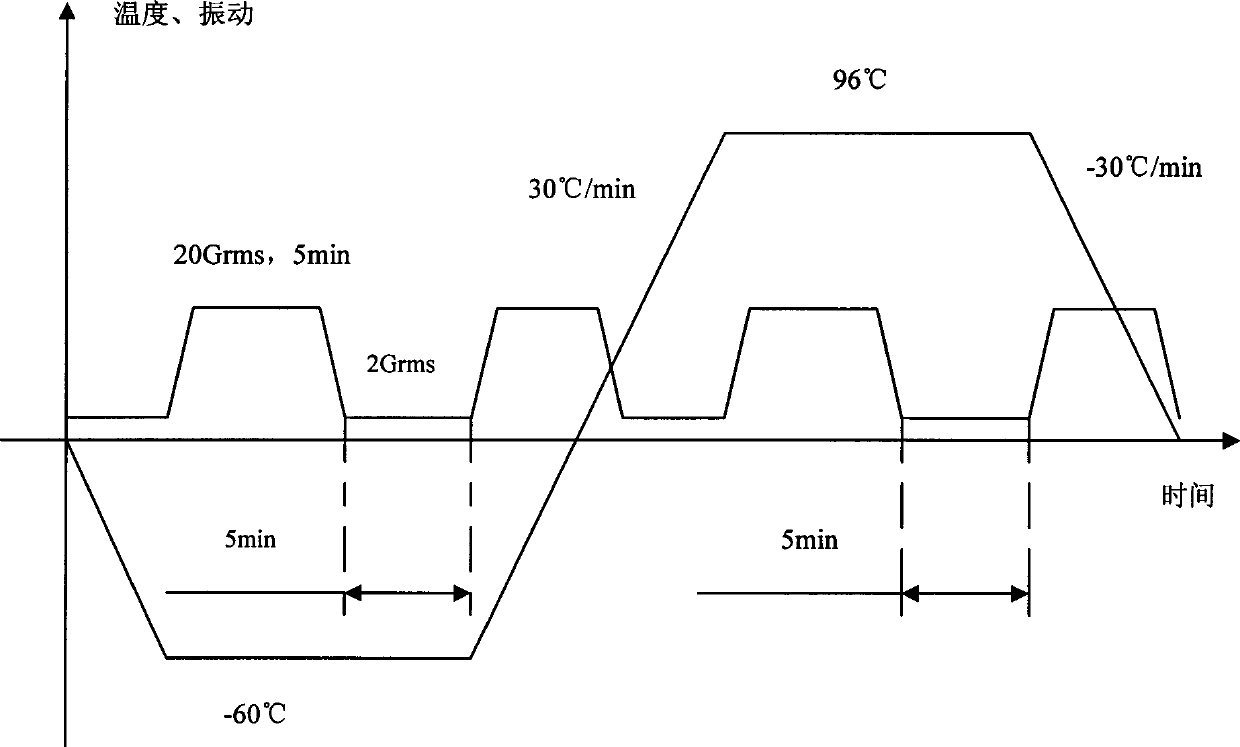

Embodiment 2

[0081] In this embodiment, a UHS1200 reliability strengthening test box, a digital multimeter, a signal source and an oscilloscope are used. The number of control boxes in this embodiment is 6 sets, 3 sets of which are used to verify the validity of the test profile, and the other 3 sets are used to verify the safety of the test profile.

[0082] This implementation example includes the following steps.

[0083] Step 1, determine the low temperature working stress limit of the control box

[0084] When determining the low temperature working stress limit of the control box, low temperature stress is applied to the control box step by step from 30°C to determine the low temperature working stress limit of the control box. The step size of applying low temperature stress is 5°C, and the cooling rate is -40°C / min. Each time the temperature reaches the specified value, keep it for 5 minutes. Allow time for the temperature balance of the control box, and then perform the performan...

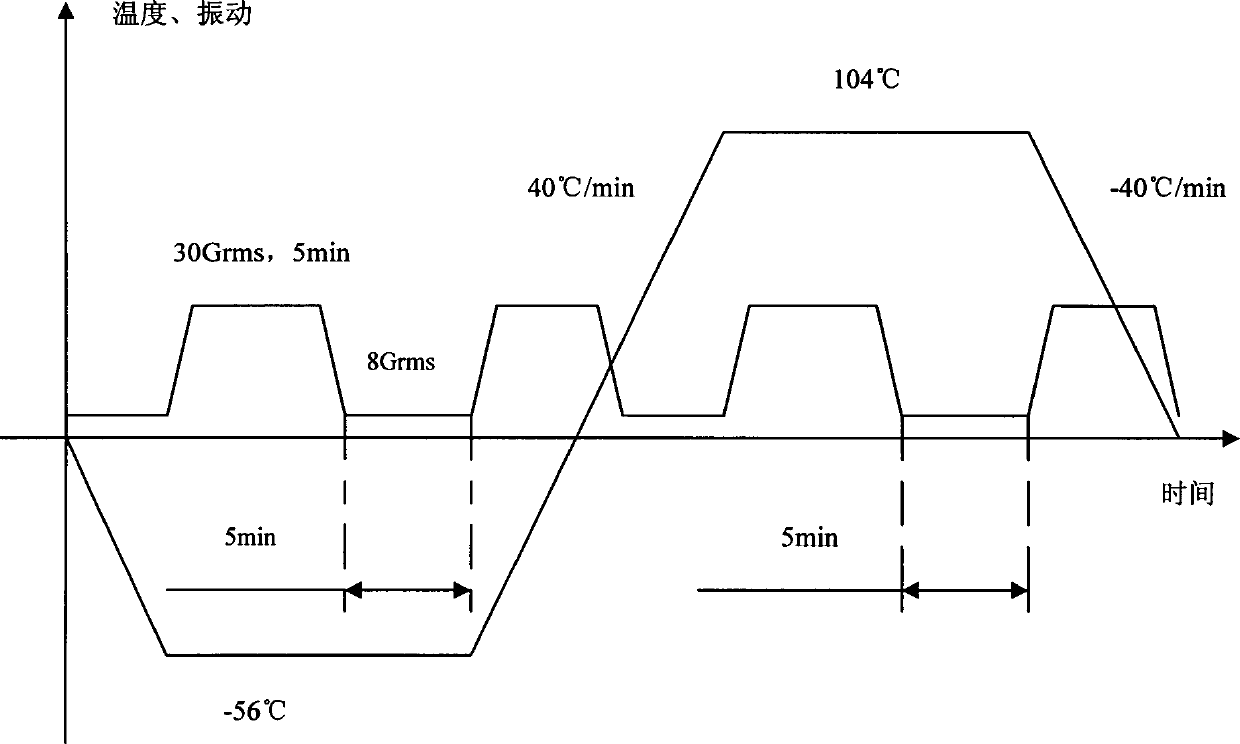

Embodiment 3

[0109] In this embodiment, the high-acceleration stress screening test profile is determined for the third type of control box, and local design improvements have been completed for the problems in the low-temperature working stress limit test, high-temperature working stress limit test, and vibration working stress limit test of the control box. .

[0110] The test of this embodiment uses a reliability enhancement test box model UHS1200, a digital multimeter, a signal source and an oscilloscope. The number of control boxes in this embodiment is 10 sets, of which 5 sets are used to verify the validity of the test profile, and the other 5 sets are used to verify the safety of the test profile.

[0111] This implementation example includes the following steps.

[0112] Step 1, determine the low temperature working stress limit of the control box

[0113] When determining the low temperature working stress limit of the control box, the low temperature stress is applied to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com