Liquid level measurement system for float bowl of hydraulic power floating type ship elevator

A liquid level measurement, floating technology, applied in the field of measurement systems, can solve the problems of unsatisfactory measurement accuracy, unreasonable cable handling, large vertical running distance, etc., to meet the requirements of liquid level measurement, accurately measure water depth, liquid The effect of high bit measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the actual working structure of the present invention is not limited to the following embodiments.

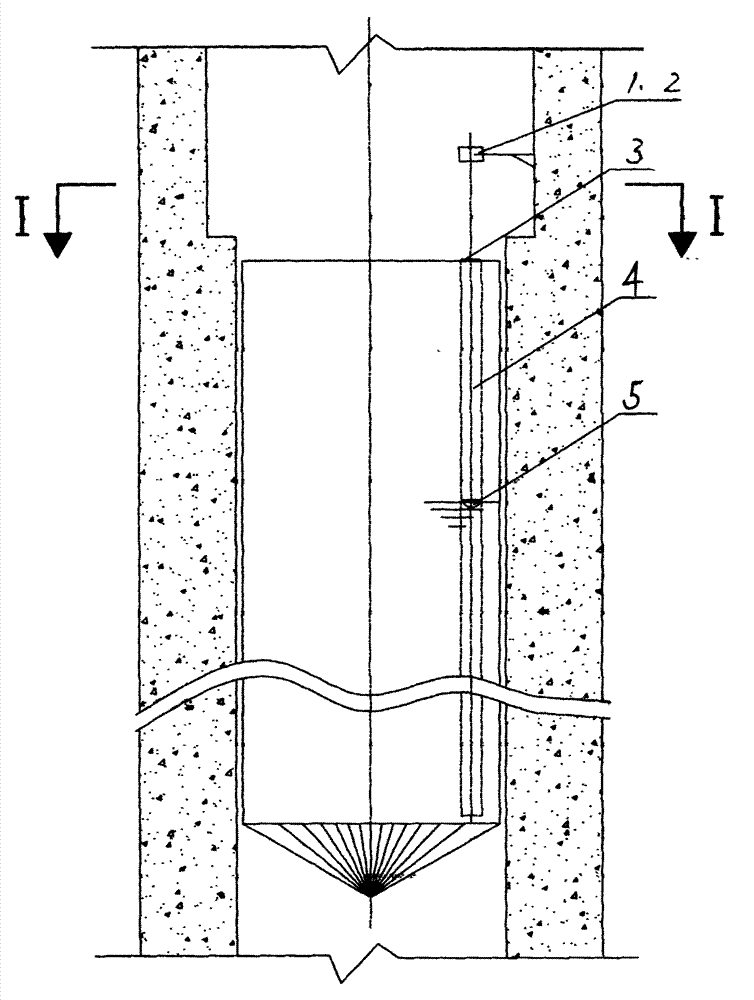

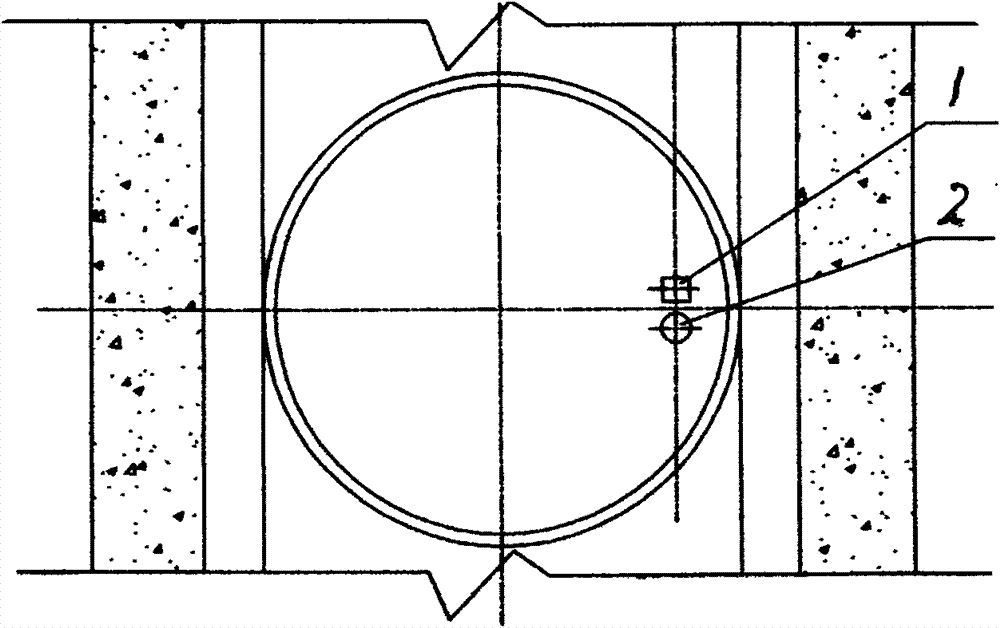

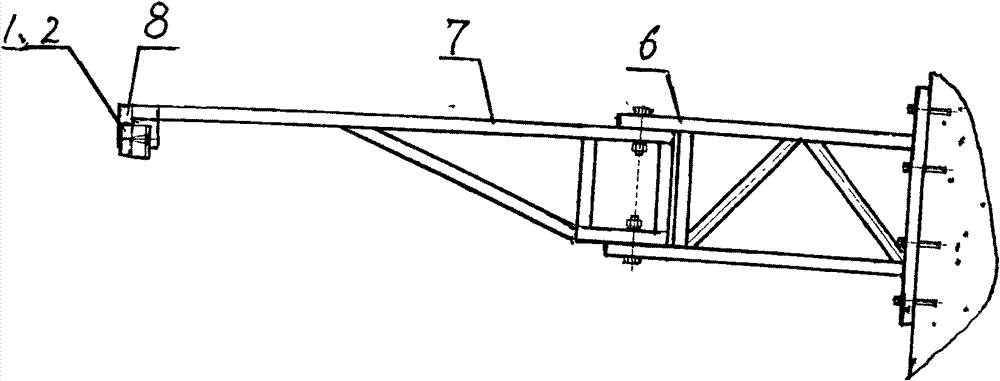

[0017] Referring to the accompanying drawings, the liquid level measurement system in the buoy of the hydraulic floating ship lift according to the present invention consists of two laser range finders 1, 2, a mounting bracket, a conventional reflector 3 and a float reflector 5 and other equipment composed, arranged as figure 1 and figure 2 shown. The two laser range finders 1 and 2 are fixed on the side wall above the buoy at the top of the shaft by means of mounting brackets. A conventional planar reflector 3 is installed on the top of the buoy, and the installation position of this plate corresponds to one of the laser range finders 3 to detect the position of the buoy. The floating ball reflector 5 is a hemispherical shell type floating ball dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com