A methanol storage tank supply and output control device for the manufacture of pharmaceuticals

An output control and storage tank technology, applied in liquid level control, non-electric variable control, control/regulation systems, etc., can solve the problem of inability to measure data quickly, reliably and accurately, to reflect methanol situation information in a timely manner, and to affect pharmaceutical raw materials. It can improve the stability and reliability, avoid irregular floating, and improve the stability of liquid level measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

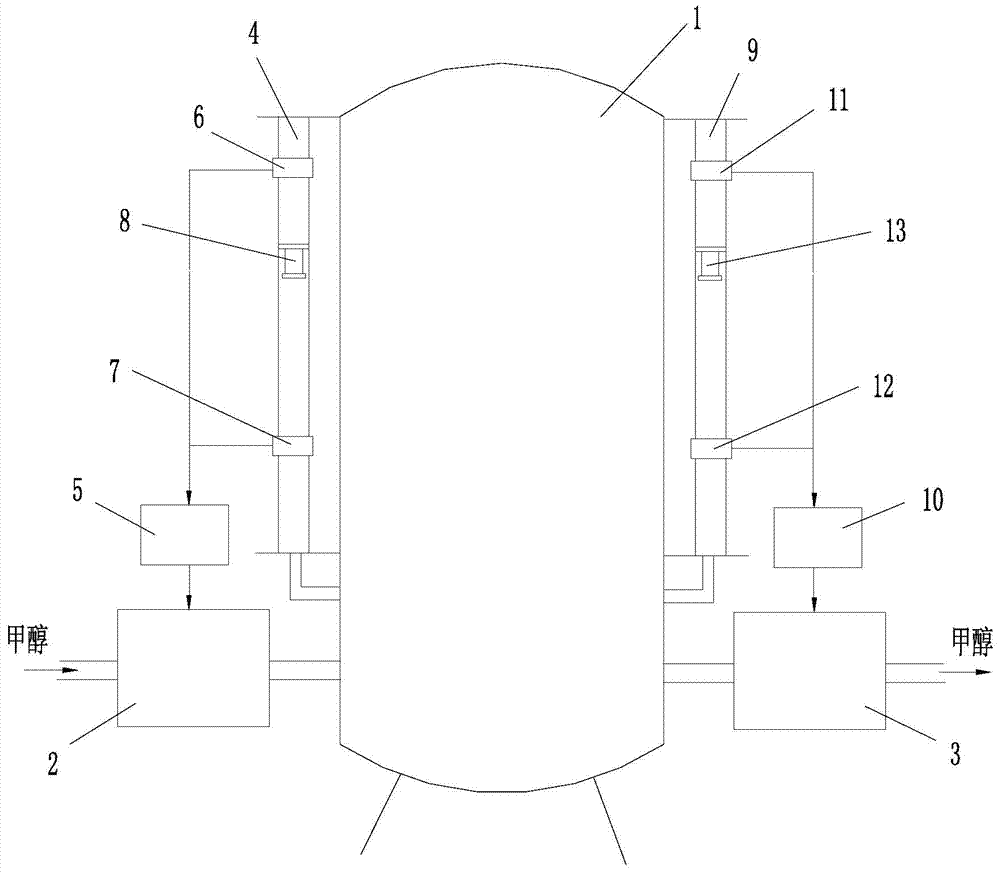

[0039] Such as figure 1 and 2 As shown, a methanol storage tank supply and output control device for the manufacture of medicines of the present invention is communicated with the methanol storage tank 1 for controlling the work of the methanol storage tank 1 supply pump 2 and the output pump 3; A control mechanism 1 for controlling the supply of methanol in the methanol storage tank 1 and a control mechanism 2 for controlling the output of methanol in the methanol storage tank 1 .

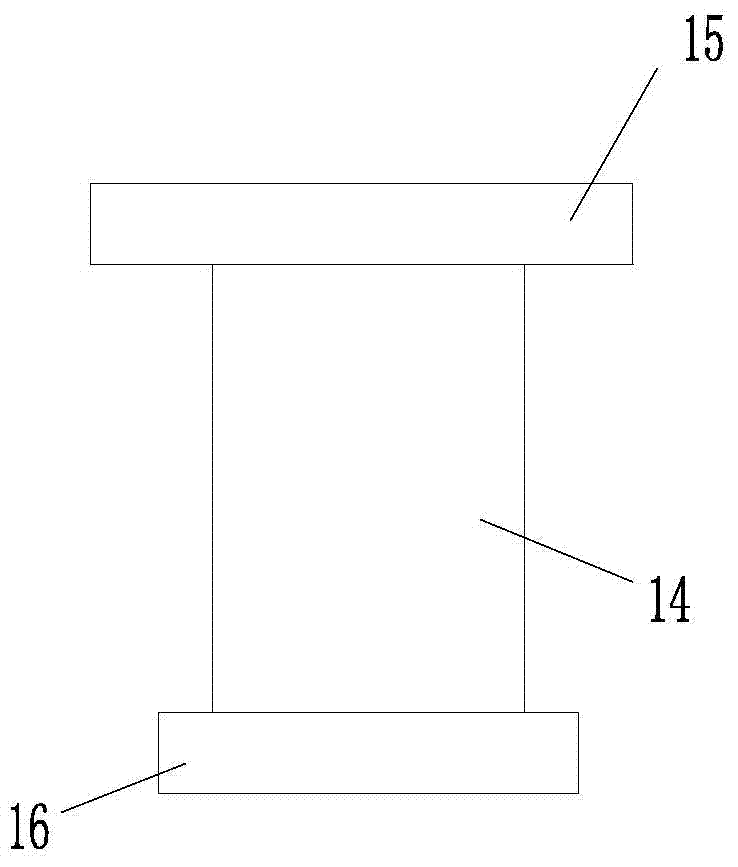

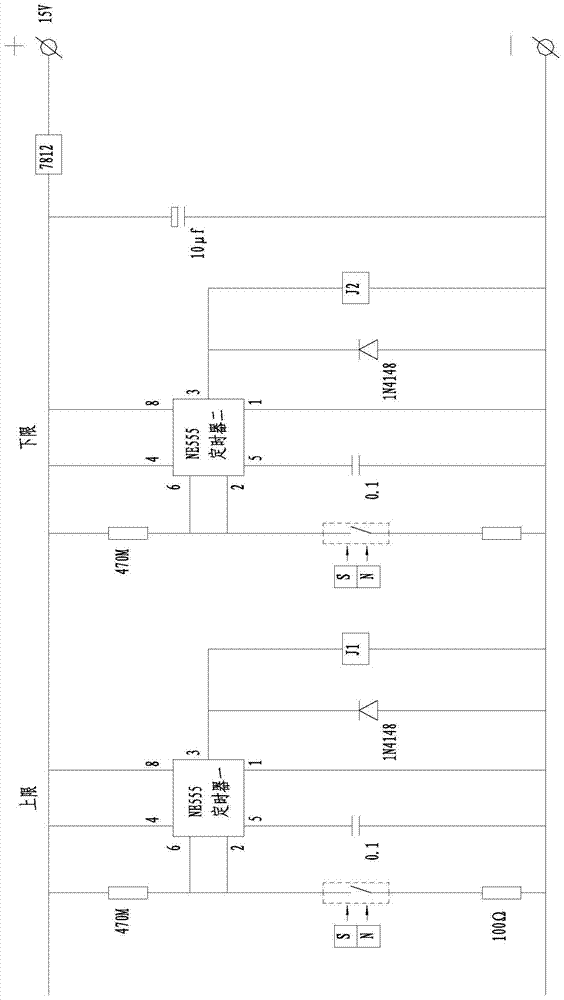

[0040] The control mechanism one includes a liquid level glass tube one 4 arranged on one side of the methanol storage tank 1 and communicated with the methanol storage tank 1 and a controller one 5, wherein two liquid level glass tubes one 4 are sheathed for detecting the liquid level upper limit and Liquid level upper limit sensor one 6 and liquid level lower limit sensor one 7 of liquid level lower limit, liquid level glass tube one 4 is built with float one 8. The input terminals of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com