Preparation method of thermoelectric refrigerator for high orbit space

A technology of thermoelectric refrigeration and thermoelectricity, which is applied to the operation mode of machines, machines using electric/magnetic effects, refrigerators, etc., can solve problems such as the inability to meet the requirements for the use of sensors in high-orbit space, and achieve vibration mechanics The effect of strong performance, high reliability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

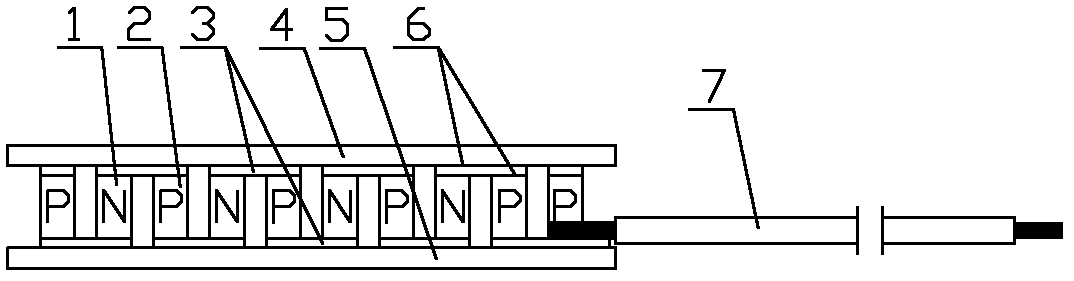

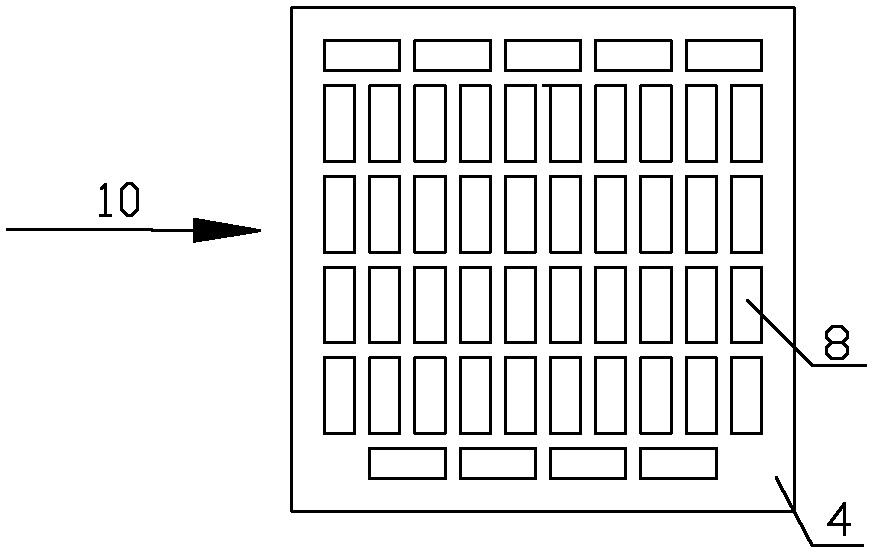

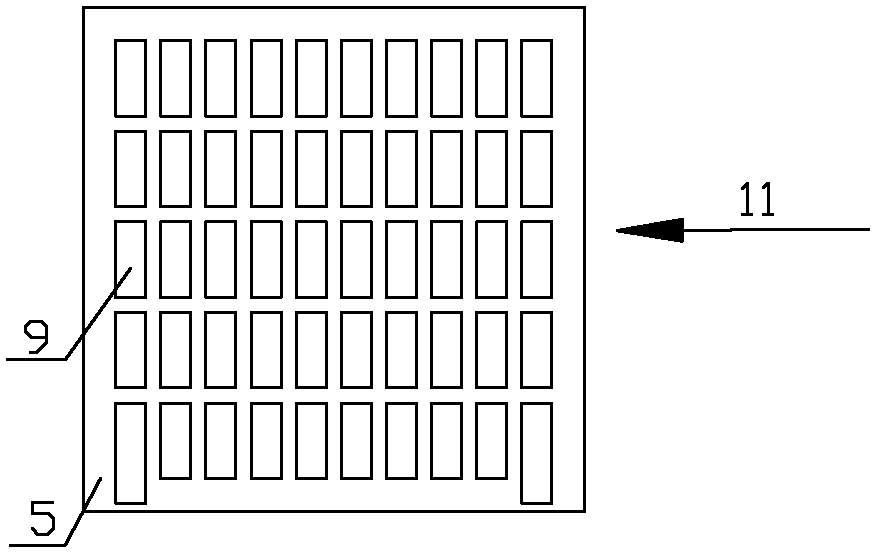

[0021] see figure 1 — image 3 .

[0022] ⑴Preparation of thermoelectric material sheets: "melting-segregation" of Bi, Te, and Sb raw materials is carried out to segregate the oxides on the surface of the raw materials and their internal impurities, and the purity of the raw materials is increased to 99.99% to make Bi 2 Te 3 rods as N-type thermoelectric material rods and Sb 2 Te 3 The rod is used as a P-type thermoelectric material rod; the thermoelectric material rod is regionally smelted, and the crystal structure of the thermoelectric material is oriented to reduce the anisotropic performance of the crystal and improve the thermoelectric performance of the material; a high-precision wire cutting machine is used to Thermoelectric mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com