High-temperature and high-pressure steam pressure reducing ball valve and production technology thereof

A high-temperature, high-pressure, ball valve technology, applied in metal material coating process, valve details, valve devices, etc., can solve the problems that single-seat control valves cannot meet the demand, are not resistant to erosion, and are easy to be damaged, so as to avoid local embrittlement , prolong the service life and reduce the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

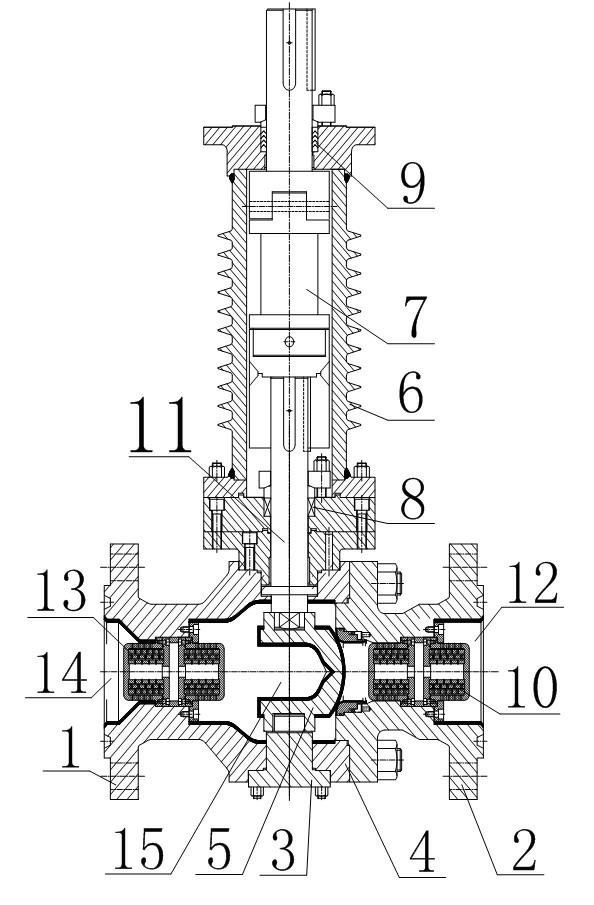

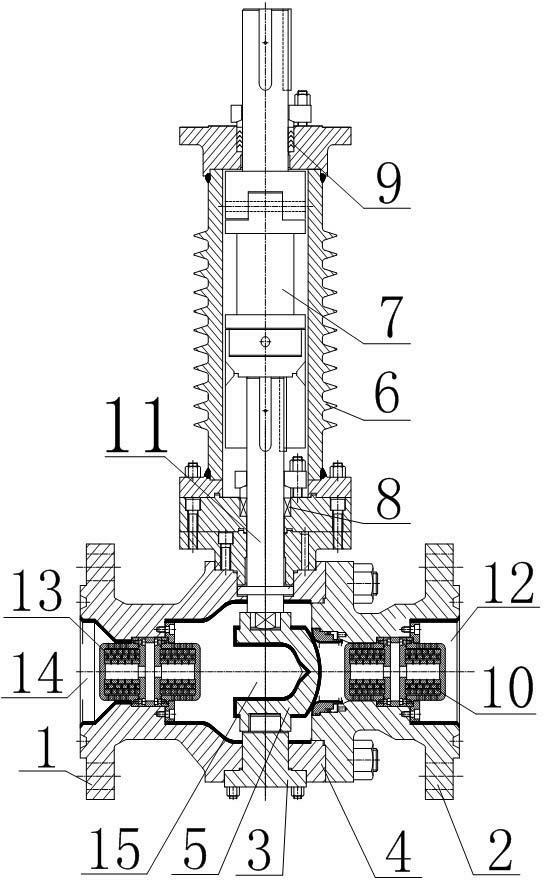

[0021] Such as figure 1 As shown, the high-temperature and high-pressure steam pressure-reducing ball valve includes a valve body 1, a V-shaped ball 5 and a left body 2 connected to the valve body 1. The valve body 1 and the left body 2 form a ball cavity, and the valve body 1 is provided with an outlet 14 and Connect the inner cavity of the outlet 14 and the sphere cavity, the left body 2 is provided with the inlet 12 and the inner cavity connected with the inlet 12 and the spheroid cavity, the inner cavity of the left body 2 is provided with a first pressure reducer 10, the valve body 1 A second pressure reducer 13 is provided in the inner cavity, wherein the first pressure reducer 10 and the second pressure reducer 13 are made of ceramic materials with a cage-type porous structure, that is, the first pressure reducer 10 and the second pressure reducer The side walls of both devices 13 form a structure with multi-layer sleeves, and each layer of sleeves is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com